Basler ElectricDECS-200-1C Digital Excitation Control System

these events occurs, the DECS-200 will log that event with a date

and time stamp. Date and time stamping of the event allows the

user to recreate a chain of events in the sequence in which they

occurred. The DECS-200 can store 127 events in volatile

memory, and those events are retrievable using BESTCOMS.

Oscillography (See Figure 6)

The data recording feature can record up to eight (8) oscillographic records stored in volatile memory. The user can select up

to six (6) variables to be monitored when triggered by the DECS200 BESTCOMS, a Logic Trigger, or a Level Trigger. Variables

that can be selected are: generator voltage, current (single

phase), frequency, kW, Power Factor, exciter field voltage, and

current.

The user can utilize the DECS-200 BESTCOMS to trigger and

save a record of a voltage step response during commissioning.

Once commissioned, a logic trigger or level trigger can be used

to activate the data recorder to capture the occurrence for review

at a later time. DECS-200 alarms can also be used to start the

data recorder. When an alarm condition occurs, an oscillographic

record can be stored. A level trigger will initiate a record to be

saved when a variable exceeds a predetermined setting. An

example of this is when the exciter field current exceeds a

predetermined setting.

The oscillographic records are recorded in accordance with the

IEEE Standard Common Format for Transient Data Exchange

(COMTRADE). Basler Electric can provide BESTWAVE, a

COMTRADE viewer, which is a program that will allow the user to

view the oscillography records saved by the DECS-200.

Communications

DECS-200 comes complete with Windows® based PC software.

This software makes the programming and customization of the

DECS-200 easy and fast. The software comes with a PID

selection program that allows the user to select stability settings

quickly and easily in a user-friendly format. The PC software has a

special monitoring function that allows the user to view all

settings, a metering screen for viewing all machine parameters,

and a control screen for remote control of the excitation system.

The RS-485 port supports Modbus™ communications protocol.

This is an open protocol with all registers and operating instructions available in the instruction manual, to make it simple for the

user to develop custom communications-based interface.

Password Protection

All DECS-200 parameters are viewable via the front panel LCD

display, the PC software or via Modbus™ without the need of a

password. If the user wishes to change a setting, the proper

password must be entered to allow access to the parameter. Two

levels of password protection exist, one for global access of all

parameters and one for a limited amount of access to parameters

normally associated with operator control.

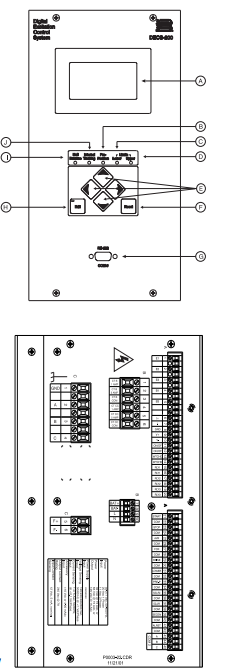

FRONT and SIDE PANEL VIEWS

The front panel HMI (Human Machine Interface) is composed of several elements, including a backlit LCD screen, six (6) pushbuttons and six (6) LEDs. The LCD is the primary interface because it conveys the majority of the information between the DECS-200 and the user/operator. Front panel pushbuttons allow the user to view menu screens and modify the various screen settings and operating conditions. The LEDs annunciate their respective states.

A) 64x128 pixel graphic LCD with backlighting. Primary source for receiving information from the DECS or when locally programming settings. Displays operations, set points, loop gains, metering, protection functions, system parameters and general settings. B) Pre-Position LED – Turns ON at the predefined setting (within the limits of the setpoints) of the current mode. C) Lower Limit LED – Turns ON at the minimum set point value of the current (active) mode. D) Upper Limit LED – Turns ON at the maximum set point value of the current mode. E) Scrolling Pushbuttons – Scrolls UP/DOWN/LEFT/RIGHT through the menu tree or when in the EDIT mode, the LEFT/RIGHT scrolling pushbuttons select the variable to change and the UP/DOWN scrolling pushbuttons change the variable. F) Reset Pushbutton – Cancels editing sessions and can be used as a quick-access to the metering screen. G) Serial Port COM0 – D-type 9 pin connector. This port is dedicated to RS-232 (ASCII commands) communication with a computer terminal or PC running a terminal emulation program such as BESTCOMS™. H) Edit Pushbutton – Enables settings changes. When the EDIT pushbutton is first pushed, an LED on the pushbutton turns ON to indicate the edit mode is active. When changes are complete (using the scrolling pushbuttons) and the EDIT pushbutton is pushed again, the LED turns OFF, indicating the changes are saved. If changes are not completed and saved within five minutes, the edit mode is exited without saving changes. I) Null Balance LED – Turns ON when the inactive modes (AVR, FCR, var, or PF) match the active mode. J) Internal tracking LED – All inactive modes (AVR, FCR, var, or PF) track the active mode to accomplish the bumpless transfer when changing active modes.

.png)

.png)

.png)