SAM Lyngsø MarineDMS2100i Bridge Manoeuvring System MAN B&W ME/ME-C Engines User Manual

Diesel Manoeuvring System, DMS2100i Page 10 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

2. DMS2100i System Overview

The DMS2100i control functions for a Propulsion Line existing of a MAN B&W two-stroke

low speed ME-Engine with Fixed Pitch Propeller are handled by one DMS2100i Gamma PLC

mounted in the DMS control cabinet, together with the units for a DPS2100 Engine Safety System.

The Main Engine Safety System is completely independent of the DMS. The Main Engine may

be equipped with a standard Safety System from the Main Engine manufacturer. If the Main Engine manufacturer supply does not include a Safety System, the DMS can be delivered together

with an independent Diesel Protection System, DPS2100 Safety System.

Other Gamma PLC's in the UMS/UCS2100 Alarm and Control System handles the alarm and

monitoring part of the machinery components controlled by the DMS2100i.

In case that alarms from the Main Engine are connected to the DMS Gamma, it must be alarms

relevant for the Main Engine controlled by that particular DMS Gamma only, because they will

be displayed as DMS alarms on the DMS Panels, such as e.g. alarms initiating a Slowdown/load reduction, startblockings etc.

The DMS2100i and the UCS2100 Alarm and Control system are independent systems, each

with its own Gamma PLC’s, only connected by a network to transfer alarms and information to

the GOS and printers (Manoeuvring Order Printer). The network will also be used for automatic operation of the Power Management System (PMS) e.g. in case of mode change to/from a

mode where the SG is connected to a Bow Thruster (BT) and/or Stern Thruster (ST).

Slowdowns for the Main Engine and optional RPM up/down signals from the Power Management System (for frequency control, load sharing and synchronising purposes) are transferred as

hardwired signal lines for safety reasons. The Slowdown inputs to the DMS2100i are defined

as supervised inputs, i.e. cable break can be detected.

All hardware component and logic circuitry of the DMS2100i and the UCS2100 Alarm and

Control System is independent. That means it will still be possible to control the propulsion

machinery even in case of a total breakdown of the Alarm and Monitoring System.

The power supply for the DMS2100i as well as the DPS2100 and UCS2100 must be Uninterruptible Power Supply (UPS) protected. There must be a separate fuse for the DMS2100i

Gamma, the DPS PLC and the remaining hardware connected to this system.

The following part of the remote control system are described in this section:

· DMS2100i Main Cabinet (Gamma PLC, I/O Modules etc.)

· DMS Panels for remote control of the propulsion machinery

· ECR Components for Manual ECR Control of the propulsion machinery

· Local Operator Panel for Local Control of the propulsion machinery

· DPS2100 Engine Safety System

· Telegraph Lever System

· Electric Shaft for Bridge Wings control

· Communication Telegraph System

· Main Engine Speed Measurement

Diesel Manoeuvring System, DMS2100i Page 11 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

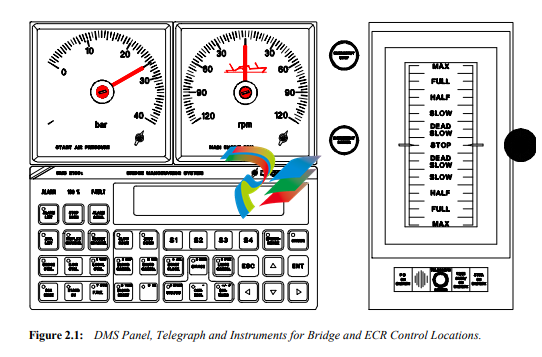

2.1 DMS Panels for Remote Control

For operation of a ship’s Propulsion Line, the DMS is connected with DMS operator panels on

all control locations, including instruments for RPM and Start air pressure indication and a

pushbutton for Emergency stop:

· one in the Engine Control Room (ECR)

· one on the Bridge

· two panels on the Bridge starboard and Port Wings (optional)

· a fifth panel can be mounted on an Aft Bridge (optional)

The DMS Panel is mounted together with a Setpoint Lever on all Control Locations with DMS

Control, i.e. normally Bridge and ECR, and optionally on the Bridge Wings.

Diesel Manoeuvring System, DMS2100i Page 12 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

2.1.1 DMS Panel Functions

The following main functions are available on each control location for the Main Engine/Propulsion Line:

Analog instruments for indication of ME RPM

Analog instruments for indication of ME Start Air pressure

Dimmer potentiometer for illumination of the analog instruments (Bridge only)

Emergency stop push-button with cover

DMS2100i Operator Panel with the following functions:

ME: <Runstat> 100.0 RPM, StAir 30.00

BAR

LIMITER:<Indic1>

TLG BC: ±120.0 ECR: ±120.0 EGS: 20.0

RPM

<Oldest unacknowledged alarm/Alarm

stat>

Four lines display with 40 characters on each line

Softkeys [ S1 ] - [ S4 ] for operation of DMS functions

Six selection keys: [ ESC ], [ ENT ]

and four [ Arrow ] keys

[ Select ] of DMS control functions of

[ Status ], [ Control ] and [ Settings ]

Diesel Manoeuvring System, DMS2100i Page 13 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

Control location selection and indication for:

[ Bridge Ctrl. ] key for indication and Request / Acknowledge of Automatic

Bridge.

References: Chapter 3.1.

[ E.C.R. Control ] key for indication and Request / Acknowledge of ECR

.png)

.png)

.png)