FUJICommunication Unit SpecificationDeviceNet

Notes on Safe Usage

In this manual, you will find various notes categorized under the following levels with the signal words “DANGER,” and

“CAUTION.”

Note that there is a possibility that the item listed with may have serious ramifications.

[General Notes]

• Never bundle control cables and input/output cables with high-voltage and large-current carrying cables such as

power supply cables. Keep these cables at least 200 mm away from the high-voltage and large-current carrying

cables. Otherwise, malfunction may occur due to noise.

• Plug connectors or sockets of the unit in the correct orientation. Otherwise, it may cause a malfunction.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

CAUTION Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury and could cause property damage.

• Turn off the power supply when you set up the unit, connect cables or perform maintenance and inspection.

Otherwise, electrical shock or damage may occur.

• Never touch any terminals while the power is on. Electric shock hazard.

• Check the appearance of the unit when it is unpacked. Do not use the unit if any damage or deformation is found.

Failure to do so may lead to fire, damage or malfunction.

• For use in a facility or for a system related to nuclear energy, aerospace, medical, traffic equipment, or mobile

installations, please consult your local distributor.

• Operate (or store) the unit under the conditions indicated in this manual and related manuals. Failure to do so

could cause fire, malfunction, physical damage or deterioration.

• Understand the following environmental limits for use and storage of the unit. Otherwise, fire or damage to the unit

may result.

- Avoid locations where there is a possibility that water, corrosive gas, flammable gas, solvents, grinding fluids or

cutting oil can come into contact with the unit.

- Avoid high temperature, high humidity, and outside weather conditions, such as wind, rain or direct sunlight.

- Avoid locations where excessive dust, salt, and metallic particles are present.

- Avoid installing the unit in a location where vibration or physical shock may be transmitted.

• Tighten mounting screws equally to a torque of 0.5 to 0.7 N•

m. Improper tightening of screws may result in fire,

malfunction, or trouble.

• Do not attempt to repair, overhaul or modify the unit at your site. Ask Hakko Electronics or the designated

contractor for repair. Otherwise, it may cause a malfunction.

• Hakko Electronics Co., Ltd. is not responsible for any damages resulting from repair, overhaul or modification of

the unit that was performed by an unauthorized person.

• Only experts are authorized to set up the unit, connect the cables or perform maintenance and inspection.

• At the time of disposal, the unit must be treated as industrial waste.

• Before touching the unit, discharge static electricity from your body by touching grounded metal. Excessive static

electricity may cause malfunction or trouble.

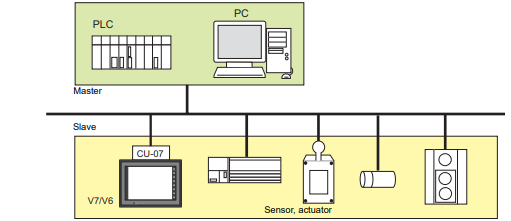

• DeviceNet is an open field network that aids in interconnecting individual control devices, such as

PLCs, computers, sensors, or actuators.

For more information on the DeviceNet, refer to the DeviceNet Specification issued by ODVA*.

* Open DeviceNet Vendor Association, Inc.

ODVA, Open DeviceNet Vendor Association, Inc., is an independent organization that controls

the DeviceNet specifications. ODVA is formed by vendors with the objective of achieving

widespread use of its DeviceNet globally

• With a communication interface unit CU-07 installed on the V series, it can communicate with other

components as a slave of the DeviceNet.

• The CU-07 supports the I/O message polling function.

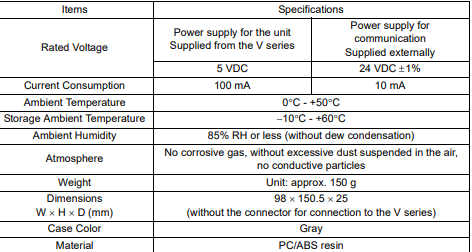

Specifications

This chapter describes the specifications for the communication interface unit CU-07.

General Specifications

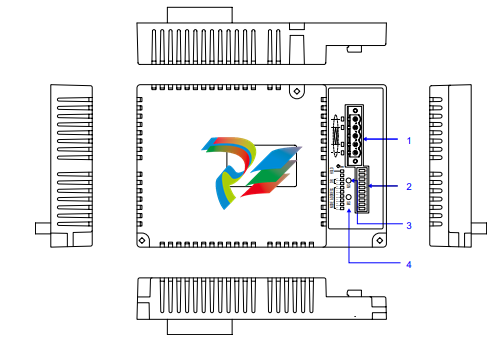

1. DeviceNet connector

This connector is used to connect the communication cable.

2. DIP switch

Choose a node address and baud rate. For more information, refer to page 7.

3. LED: NS

This LED indicates the network status. For more information, refer to page 8.

4. LED: MS

This LED indicates the node status. For more information, refer to page 8.

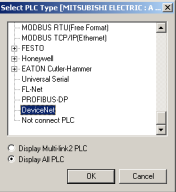

PLC Model Selection

1. Select [PLC Type] from the [System Setting] menu. The [Select PLC Type] dialog is displayed.

2. Select [DeviceNet].

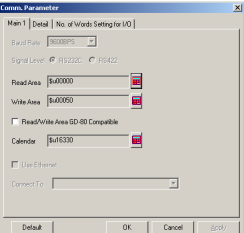

Communication Parameter

1. Select [Comm. Parameter] from the [System Setting] menu. The [Comm. Parameter] dialog is

displayed.

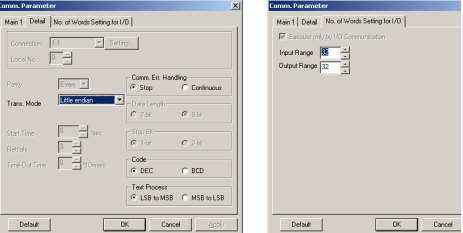

2. In the [Detail] tab window, check the desired option under [Comm. Err. Handling]. In the [No. of

Words Setting for I/O] tab window, enter desired values for [Input Range] and [Output Range].

*1 Baud rate and node address settings are made on the CU-07.

• Comm. Err. Handling

[Stop]: If any communication error has arisen, the communications are stopped. When

restoring, use the RETRY switch.

[Continuous]: If any communication error has arisen, it is indicated at the top left corner on the

screen. The V series conducts polling of the PLC, and if OK, the error state is

.png)

.png)

.png)