HoneywellEXPERION PKSSeries C I/O User's Guide EPDOC-X126-en-A November 2019

ABOUT THIS GUIDE

The procedures in this guide are intended to give you the ability to perform basic tasks with the

Series C I/O such as configuring hardware devices, continuous control strategies. Respective

forms are displayed to illustrate a procedure/concept only.

1.1 Revision History

Revision Date Description

A November 2019 Initial release of the document.

l Intended audience

l Prerequisite Skills

l References

l Terms and acronyms

1.2 Intended audience

This guide is intended for the following users:

l Persons responsible for system planning, initial hardware installation, and control strategy

configuration

l Operators who help to maintain control system operations on a day-by-day basis

l Service persons responsible for routine maintenance of control hardware, and who diagnose

and repair faults.

1.3 Prerequisite Skills

It is assumed that you should have some knowledge of Experion control systems and experience

of working in a Microsoft Windows environment.

1.4 References

Listed here are the documents that contain general information for planning and implementing

control hardware and network communications in your Experion system:

Control Hardware Planning Guide - Provides general information to assist you in planning

and design of control hardware in an Experion system. Control hardware includes C200

Controllers, Series A Chassis I/O and FIMs, also, all I/O families, (except Series C I/O). It

includes some supervisory network considerations for general reference.

l C300 Controller Guide - This guide provides information that will assist you in planning and

designing activities, as well as the installation, operation, and troubleshooting of Series C300

Controllers in an Experion system.

l Series C Fieldbus Interface Module (FIM) User Guide - Provides planning and implementation

guide for the Series C Fieldbus Interface Module.

l Fault Tolerant Ethernet Overview and Implementation Guide - Provides basic installation

instructions and configuration requirements for a Fault Tolerant Ethernet (FTE) network and

its components.

l Fault Tolerant Ethernet Installation and Service Guide - Contains instructions for installing

and configuring a Fault Tolerant Ethernet (FTE) node. The guide includes troubleshooting

and service information for an FTE node.

l Fault Tolerant Ethernet Bridge Implementation Guide - Provides information for

implementing a Fault Tolerant Ethernet supervisory network through the FTE Bridge module.

It includes module installation, configuration, operation and service data.

l Process Manager I/O Troubleshooting and Maintenance Guide - Guide features notification

messages (soft fail codes and hard fail codes), service procedures and parts lists for PM I/O

control hardware.

1.5 Terms and acronyms

The following table summarizes the terms and type representation conventions used in this guide.

Term/conventions Meaning Example

Click Click left mouse button once. (Assumes cursor is

positioned on object or selection.)

Click the Browse

button.

Double-click Click left mouse button twice in quick succession.

(Assumes cursor is positioned on object or selection.)

Double click the

Station icon.

Drag Press and hold left mouse button while dragging cursor to

new screen location and then release the button.

(Assumes cursor is positioned on object or selection to be

moved.)

Drag the PID

function block

onto the Control

Drawing.

Right-click Click right mouse button once. (Assumes cursor is

positioned on object or selection.)

Right-click the

AND function

block.

<F1> Keys to be pressed are displayed in angle brackets. Press <F1> to view

the online Help.

<Ctrl>+<C> Keys to be pressed together are displayed with a plus sign. Press <Ctrl>+<C> to

close the window.

File->New Shows menu selection as menu name followed by menu

selection

Click File->New to

start new drawing.

>D:setup.exe< Data to be keyed in at prompt or in an entry field. Key in this path

location

>D:setup.exe<.

SERIES C I/O PURPOSE

Series C I/O Modules, along with I/O Termination Assemblies (IOTAs), perform module diagnostics

input and output scanning and processing on all field I/O data and events. To allow a more

efficient use of Controller resources, I/O processing is performed separately from control

processing functions so that:

l I/O sample rates are completely independent of I/O quantity, controller loading, processing,

and alarming

l allows more efficient use of advanced Control Processor capability, and

l provides for future I/O expansion.

l Comparing Process Manager I/O and Series C I/O

l What is Series C I/O?

l Series C Pulse Input Module (SCPIM)

l What is Universal Input/Output (UIO) Module?

l What is Low Level Analog Input (LLAI) Module

l Overview of the Universal Horizontal Input/Output (UHIO)

2.1 Comparing Process Manager I/O and Series C I/O

The following list compares previous features of the Process Manager I/O and the Series C I/O:

l Non-Volatile Memory:

o In the PM, memory was maintained over a power cycle within the I/O card itself.

o With the Series C I/O, the configuration memory information is restored from the

C300 controller at power-up of the I/O Module.

l IOL - The Series C I/O link runs at twice the speed of the PMIO I/O Link. Each C300 I/O Link

can be configured to provide Series-C or PMIO link speeds.

l Series C I/O fully supports HART I/O. This includes the use of Secondary HART Variables as

control parameters.

l Separation of Primary from Secondary modules:

o In the PM, the Primary and Secondary I/O Electronics modules could be separated,

placed in different cabinets, and/or powered by different power systems.

o Series C I/O does not have this capability.

l Series C permits Zone 2 mounting of the Controller and I/O

l In PMIO, the configuration memory is maintained only if a battery backup is installed.

2.2 What is Series C I/O?

The Experion Series C I/O modules are an expanding family of traditional and special functio

input/output signal interface devices. They supports local software configuration. These I/O

modules share the same form factor as the C300 Controller and reside on the same type of

common mounting system as other Series C components.

2.2.1 What is Series C I/O Mark II?

Series C Mark II is an enhancement to the existing Series C platform in terms of IO modules,

related IOTAs, IO link, power supply, power distribution, and cabinet infrastructure, making it a

more cost-effective solution than the earlier version. The design style continues to be the same.

2.2.2 Supported Series C Mark II I/O modules

ATTENTION

Series C Mark II cannot support any PM I/Os.

C300 IOLINK block parameter IOLINKTYPE is used to determine if the IOLINK supports

Series C Mark II I/O.

IOM model

names

IOM block

name

Description No. of channels

supported

CC-PAIH01 AI-HART High Level Analog Input with HART (4)

IOM

16

CC-PAOH01 AO-HART Analog Output with HART (4) IOM 16

DC-PDIL51 DI-24 Digital Input 24V IOM w/o OWD 32

DC-PDIS51 DI-SOE Digital Input SOE IOM 32

DC-PDOD51 DO-24B Digital Output 24V Bussed Out IOM w/o

RB

32

DC-PDIS51 DI-SOE Digital Input SOE IOM 32

CC-PAIM51 AI-LLAI Low Level Analog Input Mux 16

CC-PAIH51 AI-HART AI HART IOM , R2 16

CC-PAIN01 AI-NON-HART AI IOM NON-HART 16

CC-PAOH51 AO HART AO HART IOM, R2 16

CC-PAON01 AO-NON-HART AO NON-HART IOM 16

Series C Pulse Input Module (SCPIM)

The Experion Series C PIM is an interface between C300/CN100 Controller that enables highaccuracy pulse counting of pulse streams from rotating machinery such as turbines, flow meters,

and densitometers. High-accuracy and repeatable measurement capability make the PIM well

suited for metering and custody transfer applications.

The PIM has eight input channels. Out of the eight channels, some may be single consuming one

channel or dual consuming 2 adjacent channels. The last 2 channels (channel 7 and channel 8)

can also be configured as distinct Fast Cutoff using the two output channels on the module.

Each input channel has a 32-bit counter to perform pulse counting and frequency calculation. In

addition, when these channels are configured as single input channels, these eight channels also

have a second 32-bit timer for pulse period and pulse width measurement.

Features of SCPIM

The following are some of key the features of SCPIM.

l Supports IOM redundancy.

l Supports redundant module communications with the controller via IO link.

l Supports simulation with SIM-C300/SIM-CN100 – The input value can be substituted by a

program and/or UniSim using the SIMVALUE parameter.

l Supports high accuracy frequency, period, and pulse width measurement.

l Provides hardware support for Meter Suite applications.

l Provides connections to power field devices or pulse pre-amplifiers.

l Supports pulse multiplexing that enables good pulses from a dual pulse input pair to be copied

to the Prover output interface.

l Supports Dual Pulse Integrity in accordance with ISO6551:1996 Level A, which is required to

support interfacing of custody transfer meters with pulse outputs.

l Provides the flexibility of configuring the eight input channels as single input, dual input, or a

combination of both single and dual input channels . For example you can configure the

channels as;

o 2 single input channels, 3 dual input channels or

o 6 single input channels, 1 dual input channels.

For information on PIM specifications, refer to the Specifications document available on the

Honeywell Online Support site.

Comparison between Series A and Series C PIM

The following table lists some of the differences between the Series A and Series C pulse input

modules.

Series C PIM Series A PIM

Shares the same form factor as the Series

C I/O family.

Requires two form factors to use with C300

controller; series A for the Pulse Input and the series

C form factor for the controller and other I/O

modules.

Supports IOM redundancy. Does not support IOM redundancy.

Supports Dual Pulse Integrity to support

interfacing of custody transfer meters with

pulse outputs.

Does not support Dual Pulse Integrity.

Supports pulse multiplexing that enables

good pulses from a dual pulse input pair to

be copied to the Prover output interface.

Does not support pulse multiplexing.

Supports pulse length measurement in all

channels.

Does not support pulse length measurement in the

last two channels.

Supports configuration of all eight

channels through use of PICHANNEL

block.

Needs two blocks for configuring channels:

l Pulse Input Channel block for configuring the

first six channels.

l Pulse Input Channel with Fast Cutoff block for

configuring the last two channels.

The last two channels can be configured as

Pulse Input channel types or Pulse Input

with Fast Cutoff channel types.

The last two channels can be configured only as

Pulse Input with Fast Cutoff channel types.

2.4 What is Universal Input/Output (UIO) Module?

With R410, an Universal Input/Output (UIO) module is introduced that enables you to configure

the input/output channels within a single IOM. The UIO module supports 32 channels. Each

channel can independently be configured as one of the following types.

l Analog Input channel (0-20mA or 4-20mA)

l Analog Output channel (4-20mA)

l Digital Input channel (with or without broke-wire detection)

l Digital Output channel (with or without broke-wire detection)

The UIO channels and device blocks are compatible with existing Series C AI, AO, DI, and DO

channels and blocks. In addition, each analog channel in the UIO module can be configured to

support HART input/output functionality.

l Features of UIO

l UIO features

l Differences between UIO channels and existing Series C AI, AO, DI, and DO modules

Features of UIO

The following list illustrates the key features of the UIO module

l Supports optional IOM redundancy.

l Supports simulation with SIM-C300/SIM-CN100.

l Supports HART functionality for AI and AO channel types.

l Supports multiple channel type configurations.

l Operates in an extended temperature range (-40 degree Celsius to +70 degree Celsius).

l Supports the ability to monitor the current, minimum, and maximum temperatures.

l Supports remote control when it is located within 10 kilometers from the controller.

l Supports open wire detection.

l Supports DO channel ganging from R430 onwards.

l Supports pulse counting functionality from R430 onwards.

NOTE

To use an AI HART channel in conjunction with the analog mode, it must be used on

channels 13 through 20 only. If HART is used on any of the voltage inputs, it can cause an

unstable analog PV value. The HART digital value will be unaffected.

NOTE

For information about UIO specification, refer to the latest Specification and Technical

document available on the Honeywell Online Support site.

UIO features

Support for DO channel ganging

The UIO-DO channel is now enhanced to support ganging for enabling the delivery of more

current output to the field (maximum current output of up to 2.0 Amperes). This is accomplished

using the existing UIO hardware. DO channel ganging simply requires software configuration of

up to four adjacent DO channels of the UIO module and appropriate channel wiring accordingly.

ATTENTION

l Up to four DO channels can be ganged at a time.

l UIO-channel 32 cannot be ganged with channel 1.

Support for pulse counting functionality

The UIO module DI channel is capable of providing pulse counting functionality. However, only

four DI channels (channels 15, 16, 17 and 18) support pulse counting functionality.

The UIO-DI channel pulse counting supports counting up to 10 KHz of input pulse frequency.

The UIO DI channel configuration consists of simply setting the Digital Input Type parameter to

“Accum” from the Configuration tab of the DI channel.

Differences between UIO channels and existing Series C AI, AO,

DI, and DO modules

The following table lists some of the differences between the UIO and the existing Series C AI, AO,

DI, and DO modules.

UIO module Series C AI, AO, DI, and DO modules

Supports temperature range between -40

degree Celsius to +70 degree Celsius

Supports temperature range between 0 degree

Celsius to +50 degree Celsius

Supports multiple channel type configuration Supports unique channel type configuration

2.5 What is Low Level Analog Input (LLAI) Module

Starting with R430, a new Series C compliant Low Level Analog Input (LLAI) Module is introduced

and designed to operate with the low voltage devices such as Thermocouples and RTDs. The AILLAI module supports 16 channels and accepts temperature inputs in the range of millivolts (mV).

This AI-LLAI module is identical to the existing Series C AI-LLMUX module except that the number

of channels supported by the AI-LLAI module is reduced to 16 channels. Unlike the AI-LLMUX

module, the field inputs can be directly connected to the AI-LLAI IOTA since it has its own IOTA. In

addition, the AI-LLAI module supports a new RTD input type, that is, CU50Rtd. A new library is

introduced in the standard library as "AI-LLAI."

2.5.1 Features of AI-LLAI

The following are some of the key features of AI-LLAI.

l Supports up to 16 RTDs or Thermocouple inputs.

l Operates in an extended temperature range (-40 degree Celsius to +70 degree Celsius).

l Supports a new RTD input type, CU50Rtd.

l Supports configurable Open Thermocouple Detection (OTD).

l Supports 1 second PV scanning with OTD protection.

l Supports N type thermocouple.

NOTE

AI-LLAI module does not support the following features.

l Remote cold junction capability

l User defined table

Overview of the Universal Horizontal Input/Output

(UHIO)

The Universal Horizontal Input/Output (UHIO) enables the replacement of the TDC 2000 Basic

Controllers (CB) and Extended Controllers (EC) with the Experion Series C controllers and

Universal I/Os. To enable mounting in the existing cabinets, new IOTAs are designed for the C300

Controller, Control Firewall, and the Universal I/O module such that it can fit into the space of the

CB and EC modules. However, the existing TCBxx terminal panel, and the field wiring to the TCBs

are retained. Note that different IOTAs are required for the UIO and UIO-2 modules. Either IOTA

will screw onto the back panel.

The introduction of the UHIO hardware allows customers to migrate their Hiway-based control

system to the FTE-based Experion Series C control system.

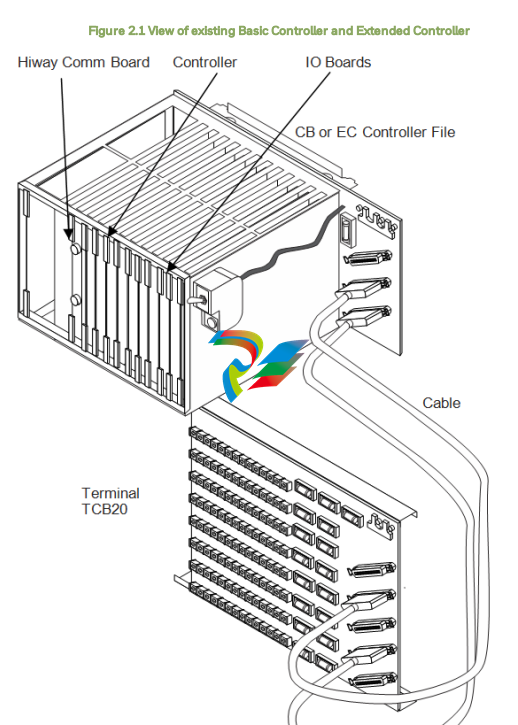

The following figure is an example of CB/EC rack that is replaced with the Experion Series C

controllers and Universal I/Os.

In these figures, the following components are shown.

l Control Firewall

l C300 Controller

l Universal I/Os

l Mapping the CB/EC racks with UHIO components

l Features of UHIO

l UHIO hardware

l Differences between the Series C IOTA and the UHIO IOTA

l About UHIO certification

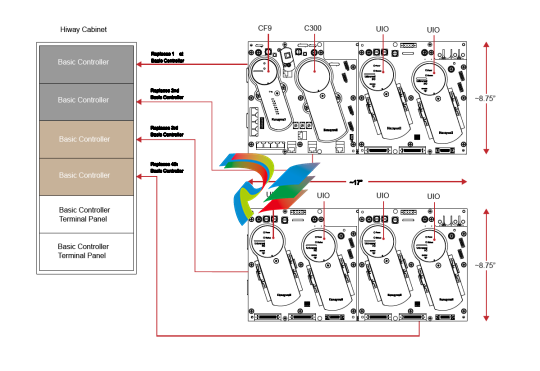

2.6.1 Mapping the CB/EC racks with UHIO components

The following figure illustrates how to map the CB/EC with the UHIO components.

ATTENTION

Note that you can increase the number of input/outputs by adding the Universal

Input/Output (UIO) modules.

2.6.2 Features of UHIO

The key features of the UHIO are:

l Supports both redundant and non-redundant configuration for C300 Controller, UIO module,

and CF9.

l Supports interchangeability of Series C components.

l Minimizes the effort for rewiring.

The UHIO also supports the following features.

l Provides mechanical connection to the TDC 2000 cabinet Backplane.

l Supports cabinet ground connections through the IOTA mounting screws.

l Provides electrical-mechanical connection to the IOM.

l Provides electrical-mechanical connection to the redundant IOL cable pair.

l Supports 24V fused electrical connections to the IOM(s) - Series C 24V and COM power supply.

l Supports a signal common ground.

l Supports precision resistors for measuring analog inputs

ATTENTION Note that you can increase the number of input/outputs by adding the Universal Input/Output (UIO) modules. 2.6.2 Features of UHIO The key features of the UHIO are: l Supports both redundant and non-redundant configuration for C300 Controller, UIO module, and CF9. l Supports interchangeability of Series C components. l Minimizes the effort for rewiring. The UHIO also supports the following features. l Provides mechanical connection to the TDC 2000 cabinet Backplane. l Supports cabinet ground connections through the IOTA mounting screws. l Provides electrical-mechanical connection to the IOM. l Provides electrical-mechanical connection to the redundant IOL cable pair. l Supports 24V fused electrical connections to the IOM(s) - Series C 24V and COM power supply. l Supports a signal common ground. l Supports precision resistors for measuring analog inputs

l Supports connection for up to 24 IO channels on the existing TCBs.

l Supports connection for up to 8 additional IO channels at a location.

l Supports manual reset input(s) for restarting a stopped UIO module.

l Supports voltage or current inputs.

l Supports hot-insertion of C300, CF9, and UIO modules.

2.6.3 UHIO hardware

The UHIO uses the following Series C IO components.

l Plug-in modules such as C300, CF9, and UIO.

l FTE network communications between the controller and Experion Station.

l I/O Link between the controller and all I/O modules.

l Series C cabinet power supply.

l Experion Station and Control Builder as operator and engineering interfaces.

ATTENTION

You cannot differentiate the appearance of the UHIO components from other Series C

components in the Control Builder or the Station though the UHIO components are

horizontally-oriented.

2.6.4 Differences between the Series C IOTA and the UHIO IOTA

The following table lists the differences between the Series C IOTA and the UHIO IOTA.

Series C IOTA UHIO IOTA

C300, CF9, and the UIO IOTA is mounted on

the Series C cabinet.

New IOTA developed for C300/CF9 IOTA and UHIO

cannot be mounted on the Series C CCA’s. It can be

mounted in a TDC 2000 basic cabinet (not a Series C

cabinet) or in a PMIO cabinet using a special

mounting bracket.

Series C UIO IOTA does not interface UIO

module to Basic Controller Terminal Panels

(TCBxx). Instead, Series C UIO IOTA is

designed to directly interface with the field

sensors/actuators.

UHIO IOTA is designed to interface the UIO module

to the Basic Controller Terminal Panels (TCBxx).

Series C IOTA is vertically mounted on the

cabinet.

UHIO IOTA is horizontally mounted on the cabinet.

Table 2.2 Differences between the Series C IOTA and the UHIO IOTA

ATTENTION

Series C Hazardous Certifications are not applicable to the UHIO components.

For more information about the C300/CF9/UHIO IOTA, see Series C Universal Horizontal

Input/Output (UHIO) components.

About UHIO certification

General Purpose Certification

The UHIO’s CSA General Purpose certification is applicable within Data Hiway (TDC 2000) cabinets

with the Series C Power supply SPS5792-142935 (HPN 51454517-100). If any modifications have

occurred since first installation, the UHIO’s CSA General Purpose certification is voided and it is

the responsibility of the end user to ensure they are still conforming to all applicable agency rules

and regulations. The original TDC Basic Power Supplies do not support the UHIO CSA General

Purpose Certification.

CE Mark certification

The UHIO's CE Mark is only applicable for installations within Data Hiway (TDC 2000) cabinets with

the Series C Power supply SPS5792-142935 (HPN 51454517-100). It is assumed that the state of

as shipped and as first installed has been maintained for all applicable installations. For

installations that do not satisfy the previously mentioned conditions, the end user is responsible to

ensure that they conform to all applicable agency rules and regulations.

CC-HUIO12

The above constraints also apply to the CC-HUIO12 IOTA. Note that the CC-HUIO12 was tested

with TCB cable 51192054 only. Using the original TCB cable 30731611 with adaptor cable 51202979

may not pass CE Mark tests. For the conducted immunity test between 150kHZ and 250kHz, the AI

accuracy was 4.3% instead of its normal 0.1% at room temperature.

SERIES C I/O PLANNING AND DESIGN

This guide is intended to provide general information to assist you in planning and designing the

installation of your Experion Series C I/O.

l General Planning References

l Series C I/O and C300 topology

l Supported Series C I/O modules

l Supported Series C I/O options

l I/O Link performance specifications

l Universal Input/Output Module-2 (UIO-2)

3.1 General Planning References

Refer to the following documents for planning and design details for the Experion system in

general and the Fault Tolerant Ethernet supervisory network. For the sake of brevity, this Guide

does not repeat the applicable general guidelines, considerations, and cautions that are covered

in these other Guides.

l Control Hardware Planning Guide

l Server and Client Planning Guide

l Fault Tolerant Ethernet Overview and Implementation Guide

TIP

For complete Series C Control System Hardware Configuration planning information, refer

to the Control Hardware Planning Guide.

l Series C I/O appearance

l Series C I/O features

3.1.1 Series C I/O appearance

The layout of Series C components supports enhanced heat management and provides a 30%

reduction in overall size (space required to mount the hardware) versus the equivalent Process

Manger set.

3.1.2 Series C I/O features

The features of Series C I/O include:

l IO Module design - tilted 18 degrees off center:

o provides for better heat distribution

o allows for efficient field wiring

l Combination of I/O Module and Field terminations in the same area. The I/O Module is

mounted on the IOTA, which reduces cabinet space and eliminates items such as FTA

connection cables.

l Redundancy is done directly on the IOTA by simply adding a second IOM to the IOTA (with the

exception of the C300 controller).

For complete feature/functions for the following modules/IOTAs, refer to the Experion Series C

I/O Specifications document.

I/O

module/IOTA

Feature/function

Analog Input

w/HART

l Extensive self-diagnostics

l Optional redundancy

l HART capable, multi-variable instruments

l Fast (50ms) loop scan

l PV protection through a broken-wire detection diagnostic

l All channels configured for 4-20 mA inputs can detect broken

field wires. A soft failure alerts the maintenance staff for

corrective action.

l Non-incendive field power

l Non-incendive power for 4-20 mA loops is provided with no

external marshalling.

Analog Input

non-HART

l Extensive self-diagnostics

l Optional redundancy

l Fast (50ms) loop scan

l Non-incendive field power

Analog Output

w/HART

l Extensive self-diagnostics

l Optional redundancy

l HART capable, multivariable instruments

l Safe-state (FAILOPT) behaviors

l Each channel can be configured to HOLD, LAST, VALUE, or

SHED to a SAFE VALUE.

l Output read back checking of current delivered to the field

l PV protection through a broken-wire detection diagnostic

l Each channel can detect broken field wire. A soft failure alerts

the maintenance staff for corrective action.

l Non-incendive output

l No external marshalling required to support the 4-20ma loop,

and still provides for channel power protection.

Analog Output

non-HART

l Extensive self-diagnostics

l Optional redundancy

I/O

module/IOTA

Feature/function

l Safe-state (FAILOPT) behaviors

l Each channel can be configured to HOLD, LAST, VALUE, or

SHED to a SAFE VALUE.

l Output read back checking of current delivered to the field

l Non-incendive output

Digital Input

24VDC

l Extensive self-diagnostics

l IOM redundancy

l Input direct/reverse

l Internal or external field power selections

l Galvanic isolation

l PV protection through a broken-wire detection diagnostic

l Each channel can detect broken field wire. A soft failure alerts

the maintenance staff for corrective action.

l Non-incendive output

l No external marshalling required to support the 4-20ma loop,

and still provides for channel power protection.

Direct Input

High Voltage

l Extensive self-diagnostics

l Optional redundancy

l Input direct/reverse

l Galvanic isolation

Digital Input

High Voltage

PROX

l Extensive self-diagnostics

l Input direct/reverse

l Galvanic isolation

Direct Input -

Sequence of

Events

DI-SOE

l Extensive self-diagnostics

l Optional redundancy

l 1ms Sequence of Events for Discrete Inputs

l Low Latency / High Speed Scanning mode

l Broken wire detection

l Supplies non-incendive field power

l On board excitation power (no need for marshalling power)

l Direct / Reverse Input Indication

Galvanic isolation

Direct Output

bussed 24Vdc

l Extensive self-diagnostics

l Functional redundancy

l Output direct/reverse

l Safe-state (FAILOPT) behaviors

l Each channel can be configured to HOLD, LAST, VALUE, or

SHED to a SAFE VALUE.

l Fuse-less short circuit protection

allows a short circuit to exist without blowing any fuses. When a particular

channel is shorted, internal circuits detect this and remove power to the

I/O

module/IOTA

Feature/function

field connection. The channel remains de-energized until the short circuit

is repaired

l Latched, pulsed or pulse-width modulated output

l Galvanic isolation

l Output read back checking to screw terminal

Digital Output -

Relay IOTA

l Galvanic isolation

l Counter EMF snubbing circuit

l Isolated dry contact (Form A or B)

l Output read back checking on system side of driver

Low Level

Analog

(temperature)

Input - LLMUX

l TC and RTD operation

l Remote cold junction capability

l 1 Second PV scanning with OTD protection

l Configurable OTD protection (See below)

l Temperature points can be added in 16 point increments

Low Level

Analog

(temperature)

Input - LLAI

l Thermocouple (TC) and RTD operation

l 1 Second PV scanning with Open Thermocouple Detection (OTD)

protection

l Configurable OTD protection

Speed

Protection

Module - SP

l Supports 2/3 voting logic for speed and acceleration.

l Supports multiple configurable trip limits for speed and acceleration.

Servo Valve

Positioner

Module - SVPM

l Supports PID execution and position calibration.

l Computes valve position from LVDT/RVDT input signal and controls valve

by signaling the Servo coil.

l Provides current modulation to avoid stiction in controlled device (servo

valve).

Pulse Input

Module - PIM

l Highly accurate frequency/period calculations.

l Supports Dual Pulse Integrity in accordance with ISO6551:1996 Level A for

custody transfer applications.

l Extensive self-diagnostics.

l Functional redundancy.

l Provides channel-to-channel and terminal block to backplane voltage

isolation.

Universal

Input/Output

Module - UIOM

l Extensive self-diagnostics

l Optional redundancy

l Independently configurable I/O channels

l controls DI, AI, DO, AO

l HART capable, multivariable instruments

l PV protection through a broken-wire detection diagnostic

l Safe-state (FAILOPT) behaviors

l Supports multiple channel configurations

UIO-2

I/O

module/IOTA

Feature/function

In addition to all features supported by UIO, the UIO-2 supports the folowing

additional features:

l Provides one HART modem per I/O channel

l Supports pulse counting on up to four of any of the 32 channels

configured as DI

l Supports DO ganging within the following eight channel number groups: 1

- 4, 5 - 8, 9 - 12, 13 - 16, 17 - 20, 21 - 24, 25 - 28, and 29 – 32. However,

ganging across these groups is NOT possible

Beginning with ExperionR501, the following new features are available:

l Supports SOE on any channel

l Supports NAMUR inputs. This function, however, will require external

voltag

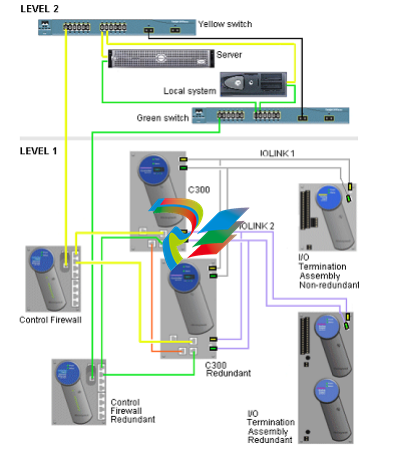

Series C I/O and C300/CN100 topology

ATTENTION

Topology for the Series C I/O and C300 - 20mS CEE Controller is similar to the Series C I/O

and C300 - 50ms Controller, with the exception that the C300 - 20mS CEE Controller does

not support the PMI/Os. CN100 supports all the Series C family of I/Os with the exception of

SPM and SVPM.

Series C I/O is attached to an IOLINK that is being mastered by a C300 controller. It is important to

note that:

l IOLINK - Serves as data repository for IOM function blocks in Control Builder to provide

communications interface with Series C I/O.

l Series C I/O cannot reside on an IOLINK mastered by an IOLIM or xPM.

Examining the topology rules

The following are the topology rules relating to the Series CI/O environment.

Refer to the following document for graphical representations of cabinet layouts depicting Series

C, PMIO, FIM, and LLMUX hardware configurations. Control Hardware Planning Guide

Item Impact Description

Redundancy None Redundancy capacity and performance is displayed while

redundancy is present.

Switchover Same as PM

I/O

Series C I/O hardware and/or software can switchover, recover,

and resume full view in a timeframe no greater than PM I/O.

Initialization All Series C I/O

per

C300/CN100

Can be initialized in 60 seconds (+/- 25%) after cabinet-level loss

power loss.

I/O module Can be initialized in 10 seconds (+/- 25%) after IOM level loss

power loss.

Multiple I/O

Links

2 Design allows the use of multiple Series C I/O Links in the same

cabinet.

tem Impact Description

I/O Link

performance

None I/O Link networks perform at the current distance and IOP count

specifications.

I/O Link

capacity

40 max Maximum of 40 redundant IOMs per link

(for either Series C I/O or PM I/O).

IOMs / C300 64 max Maximum of 64 redundant IOMs per C300 (for PM I/O).

80 max Maximum of 80 redundant IOMs per C300 (for Series C I/O).

Series C and

PM I/O -

combined

64 Design supports Series C and PM I/O FTAs in the same side of the

cabinet. Current configuration prevents IOTA and FTAs in the

same column.

I/OMs/CN100 40 Max Maximum of 40 redundant I/OMs per CN100

3.3 Supported Series C I/O modules

The list of I/O modules below can be used on a Series C IOLINK. The IOLINK contains a function

that enables programming and reprogramming the executable image (rather than substitution of

a removable hardware component). The preferred method of delivery of the image is over the

IOLINK.

Refer to Life Cycle changes for Series C IO modules and IOTAs section for life cycle update.

TIP

Series C IOLINK cannot contain any PM I/O IOPs.

C300 IOLINK block parameter IOLINKTYPE is used to determine if the IOLINK supports

either Series C I/O or PM I/O.

IOM

model

names

IOM block

name

Description # of

chnls

Similar to

PMIO type

IOP

model

names

CUPAIH01

CCPAIH01

AI-HART High Level Analog Input with HART

(supports differential inputs on only

channel 13 through channel 16)

Refer to Attention

16 HLAIHART

CCPAIH02

AI-HART2 High Level Analog Input with HART

((supports differential inputs on all 16

channel)

16 HLAIHART

CCPAIX02

AI-HART2 High Level Analog Input with

Differential/Single-ended non-HART

(supports differential inputs on all 16

channels)

16 HLAI

CCPAIX01

AI-HL1 High Level Analog Input with Differential

non-HART

(supports differential inputs on only

channel 13 through channel 16)

16 HLAI

NOTES:

1. There are two models of High Level Analog Input such as, CU-PAIX01 and CU-PAIN01. The

Module Hardware and the corresponding IOTAs are different and CU-PAIN01 is a new model.

From the perspective of configuration and implementation, both High Level Analog Input

models use the same IOM Block such as, AI-HL. It must be noted that the two models utilize

the same configuration; online migration is not possible as mixed redundant pair is not

possible. There are two models of Analog Output such as, CU-PAOX01 and CU-PAON01.

Hence, similarly configuration, implementation, and interoperability constraints apply and CUPAON01 is the new model.

2. Two new models of AI-HART (CC-PAIH02) and AI-HL (CC-PAIX02) modules are introduced to

replace the older models of the AI-HART (CC-PAIH01) and AI-HL (CC-PAIX01) modules. The

new models support both single-ended and differential inputs.

3. With R410, a new model of HART Analog Input CC-PAIH51 is introduced. The HART Analog

nput CC-PAIH51 and Cx-PAIH01 use the same IOM block, that is, AI-HART. The configuration

and implementation mentioned in note 1 applies to the HART Analog Input module.

4. With R410, a new model of HART Analog Output CC-PAOH51 is introduced. The HART Analog

Output CC-PAOH51 and Cx-PAOH01 use the same IOM block, that is., AO-HART. The

configuration and implementation mentioned in note 1 applies to the HART Analog Output

module.

5. With R410, a new model of Digital Input 24V DC CC-PDIL51 is introduced. The Digital Input

24V DC CC-PDIL51 and Cx-PDIL01 use the same IOM block, that is, DI-24. The configuration

and implementation mentioned in note 1 applies to the Digital Input 24V module.

6. With R410, a new model of Digital Output 24V DC CC-PDOD51 is introduced. The Digital

Output 24V DC CC-PDOD51 and Cx-PDOB01 use the same IOM block, that is, DO-24B. . The

configuration and implementation mentioned in note 1 applies to the Digital Output 24V

module.

7. Starting with R430, a new model of Low Level Analog Input Mux CC-PAIM51 is introduced.

8. The UIO (CC-PUIO01) has 32 configurable input or output channels. Each channel can be

configured as one of the following:

l Analog Input (0-20mA or 4-20mA active)

l Analog Output (4-20mA active)

l Digital Input (with or without line monitoring)

l Digital Output (with or without line monitoring)

9. The UIO (CC-PUIO31) module is introduced with R432 and has 32 configurable input or output

channels that are identical to the UIO (CC-PUIO01) module.

ATTENTION

Series C IO modules introduced in ExperionPKS R410.x release should not be used

with its prior ExperionPKS releases R400.x. Do not try to downgrade the firmware of

Series C IO Modules introduced in ExperionPKS R410.x release, as IOM will not

work and it is difficult to recover as well.

l Compatibility matrix between AI modules and differential AI modules

l Compatibility matrix between AO modules and differential AO modules

l Difference between AI-HART modules Cx-PAIH01 and Cx-PAIH51

l Difference between AO-HART modules Cx-PAOH01 and Cx-PAOH51

l Difference between bussed low voltage Digital Input modules Cx-PDIL01 and Cx-PDIL51

l Difference between low voltage Digital Output modules Cx-PDOB01 and Cx-PDOD51

l Difference between AI-LLMUX and CC-PAIL51 modules Cx-PAIM01 and Cx-PAIM51

l Identifying supported Series C I/O modules

l Considerations for replacing or pairing Series C Analog I/O modules in a redundant

configuration

3.3.1 Compatibility matrix between AI modules and differential AI

modules

You can choose the AI modules based on your functionality requirements. The following table lists

the functionalities and the respective AI modules.

.png)

.png)

.png)