AlstomT1693EN Technical Manual Rev. 09

Care has been taken with the design of this product to ensure that it is safe. However, in common with all

products of this type, misuse can result in injury or death. Therefore, it is very important that the

instructions in this manual and on the product are observed during transportation, commissioning,

operation, maintenance and disposal.

This technical manual must be regarded as part of the product. It should be stored with the product and

must be passed on to any subsequent owner or user.

Local safety laws and regulations must always be observed.

Persons working on the product must be suitably skilled and should have been trained in that work for

these products.

The product is a component designed for incorporation in installations, apparatus and machines.

The product must not be used as a single item safety system. In applications where maloperation of the

product could cause danger, additional means must be used to prevent danger to persons.

Product approvals and certifications will be invalidated if the product is transported, used or stored outside

its ratings or if the instructions in this manual are not observed.

Third party approvals to safety standards UL508C and CSA C22.2 No 14 are marked on the product.

In the European Union

• Products within the scope of the Low Voltage Directive, 2014/35/EU are CE marked.

• The product complies with the essential requirements of the EMC directive 2014/30/EU, when

installed and used as described in this manual. The requirements of the EMC Directive should

be established before any installation, apparatus or machine which incorporates the product

is taken into service.

• A machine must not be taken into service until the machine has been declared in conformity

with the provisions of the Machinery Directive, 2006/42/EC.

INTRODUCTION

1.1 GENERAL DESCRIPTION

An MV3000e DELTA a.c. drive is used to control a motor, generator, or power conditioning application.

It uses a modular approach which allows the use of a small number of common components to create a

large number of system variants

Advantages Of The Modular System

• The DELTA transistor and rectifier modules are of a standard mechanical design, using the

same mounting method and dimensions;

• DELTA rectifier and transistor modules can be connected in parallel to provide a wide range of

power levels;

• Modular construction makes maintenance and repair work simple, and enables rapid module

replacement;

• DELTA transistor and rectifier modules can be withdrawn on a simple slide system for ease of

assembly and maintenance.

• Ease of handling – smaller, lighter modules are assembled to form large drives.

DELTA Product Range

• Rectifier module;

• Transistor modules;

• MV3000e Controller

• SMPS (Switch Mode Power Supply) units;

• User I/O termination panel;

• MVM (Mains Voltage Monitor);

• DDM (Drive Data ManagerTM)– Keypad;

• Reactors and transformers;

• Installation accessories (mounting kits and control cables).

ASSOCIATED MANUALS

• T1676 – MV3000e Getting Started Manual (for rectifier fed systems);

• T1679 – MV3000e Software Manual (and Firmware Supplement T2154);

• T2002 – MV3000e Getting Started Manual (for AEM systems).

The T1676 and T2002 manuals include commissioning and operating details for the complete MV3000e

DELTA drive.

The T1676, T1679 and T2002 manuals should be regarded as part of the DELTA product. Individual DELTA

component instructions sheets that may also be required are shown below:

• T1694 MVS3007-4002 - Profibus Field Coupler 12 Mb/s;

• T1915 MVS3000-4001 – Drive Data Manager TM (keypad);

• T1916 MVS3001-4001 - Keypad mounting kit;

• T1930 MVC3006-4003 – Mains Voltage Monitor (MVM);

• T1968 MVS3011-4001 - CANbus communications module;

• T1973 MVC3003-40xx – Switch Mode Power Supply (SMPS) Module;

• T2034 MVS3012-400x - Ethernet interface;

• T2100 MVDL800 DELTA Transistor Module;

• T2101 MVDL1000 DELTA Transistor Module;

• T2112 MVC3001-400x – DELTA Controller

Section 1 – Introduction

• Overview of the main concepts used in DELTA drives;

Section 2 – Specifications

• Common environmental data for the DELTA product range;

• Gives individual DELTA component data.

Section 3 – Complete Drive Module (CDM) Design

• Guidance for component selection;

• Enclosure design;

• Cooling system design;

Section 4 – Power Drive System (PDS) Design

• Motor requirements;

• Motor and supply cable selection;

• Encoder details.

Section 5 – Complete Drive Module (CDM) Assembly

• Guidance for assembly of DELTA components into an enclosure.

Section 6 – CDM Commissioning

• Guidance for commissioning the CDM, including electrical safety checks and functional

testing.

Section 7 – PDS Commissioning

• Guidance for commissioning the CDM in the final location.

Section 8 – Maintenance

• Diagnostic information;

• Preventative maintenance;

• Module replacement.

Section 9 – Disposal

Appendices

• Mechanical drawings of DELTA components;

• Electrical connection diagrams

• Torque values.

DRIVE CONFIGURATIONS

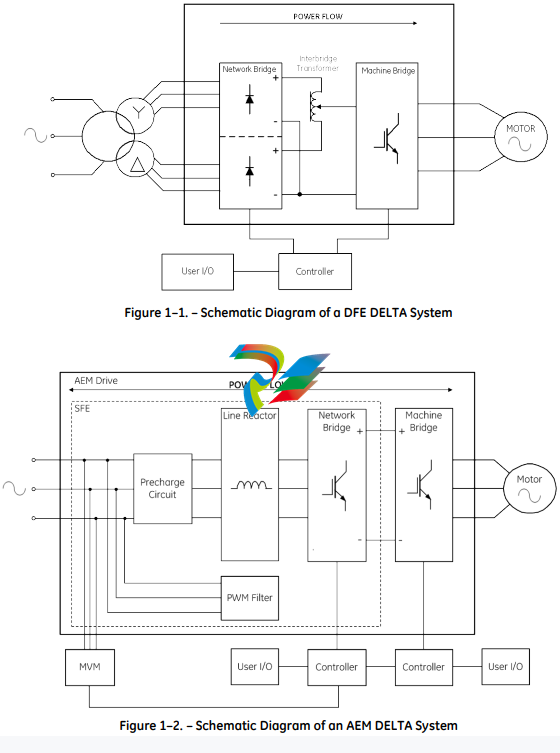

A DELTA drive consists of two ‘bridges’ – the network bridge and the machine bridge.

Two generic configurations are available, each with a different network topology:

• Diode Front End (DFE) – power transfer from the network to the load only;

• Active Energy Management (AEM) – power transfer to and from the network.

Both the DFE and AEM drives share the same machine bridge topology.

Figure 1–1 is a simplified schematic diagram of a DFE system. Figure 1–2 is a simplified schematic diagram

of an AEM system.

Circuit diagrams for the various drive configurations are included in Appendix B: Electrical Connection

Diagrams.

1.4.1 DFE Network Bridge

A DFE network bridge comprises of one or more diode rectifier modules, plus ancillary components, which

could include:

• Line reactor;

• Fusing;

• Pre-charge circuit;

• Interbridge transformer;

• D.C. Link inductor.

The network bridge converts the a.c. supply to an unsmoothed d.c. voltage. Power flow is from the network

supply only.

Harmonic currents produced in the supply system by variable speed drives with uncontrolled rectifier inputs

may be reduced by changing from 6 pulse to 12 pulse (6 phase) input.

In the case of a 12 pulse input:

• A phase shifting transformer is used to produce the additional 3 phases which are phase

shifted by 30° as shown in Figure 1–1. These two sets of three phase supplies are rectified by

two rectifier bridges.

• Instantaneous voltage differences, between the outputs of the two rectifiers, are absorbed by

an interbridge transformer connected between the two positive outputs of the rectifiers. The

output to the d.c. link is taken from the centre-tap of the interbridge transformer.

1.4.2 Sinusoidal Front End (AEM Network Bridge)

The network bridge of an AEM drive comprises of one to six DELTA transistor modules. The network bridge

is combined with the following ancillary components to form a Sinusoidal Front End (SFE):

• Line reactor;

• Fusing;

• PWM filter;

• MVM unit;

• Sharing reactors;

• MV3000e Controller.

The SFE bridge can be used to convert the a.c. supply to a d.c. voltage, but also has the capability to allow

regeneration of energy back into the network, and as such is required for power generation applications

(e.g. wind turbines).

The AEM network bridge provides a very clean voltage waveform, but the harmonic content will require

filtering.

1.4.3 Machine Bridge

The machine bridge converts between a d.c. and an a.c. voltage of variable frequency and amplitude.

Generally in a DFE system, the power flows from the d.c. link, out into the a.c. load. In an AEM system, power

flow is bi-directional.

The machine bridge comprises of one to six DELTA transistor modules and the following ancillary

components:

• Sharing reactors;

• Fusing;

• MV3000e Controller.

2.7.1 Electrical Connections

The connections from the SMPS unit to other equipment in the DELTA drive are as follows:

• One 40 way ribbon cable, supplied as part of the DELTA transistor module;

• A two pin connector plugs into the d.c. link of the associated DELTA transistor module.

2.8 MV3000E DRIVE DATA MANAGERTM (KEYPAD)

Units covered: MVS3000-4001 (DDM)

MVS3001-4001 (Installation kit)

The Drive Data ManagerTM, shown in Figure 2–6, is an ergonomically designed keypad which provides the

functionality to configure a drive system. It also provides motor control and diagnostic functions.

The Drive Data ManagerTM derives its power supply from the MV3000e Controller

An installation kit containing a waterproof gasket and a lead is available separately. The lead for

connection from the Keypad to the MV3000e controller has a maximum length of 3 m (9.8 ft.). This lead

length determines the relative positions of the Drive Data ManagerTM and the controller. When supplied

with a waterproof gasket, it can be mounted on an enclosure door to meet IP 65 enclosure protection.

The specification for the Drive Data ManagerTM and its electrical connections, are included in the T1915

Instruction Sheet which is supplied with the Drive Data ManagerTM.

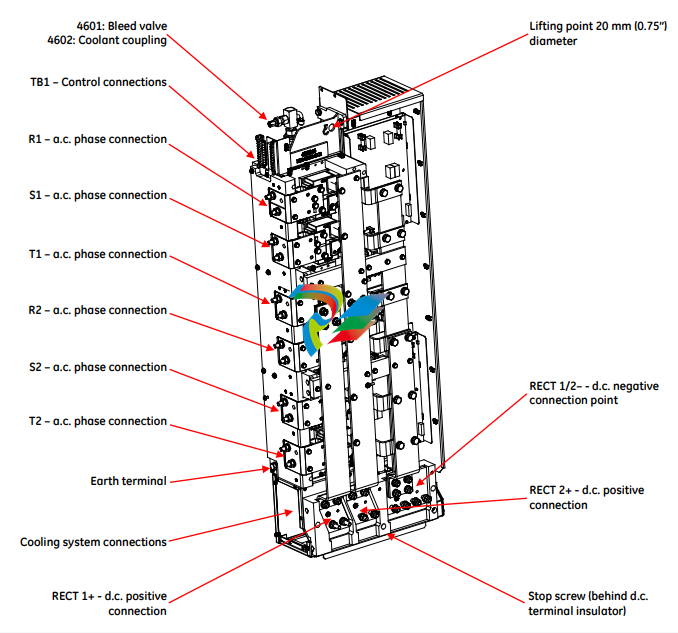

2.9 DELTA RECTIFIER MODULE

Unit covered: MVRL2100-4601.

MVRL2100-4602.

In a DELTA drive system, rectifier modules shown in Figure 2–7, are used in network bridges to convert an

a.c. supply into a rectified, unsmoothed d.c. supply.

The rectifier module is available in a single rating. Larger rectifier power ratings can be achieved by

connecting the modules in parallel (derating will be necessary, see Section 2.9.4.1: Parallel Ratings).

Each module has a pair of three-phase, six pulse rectifiers, with individual a.c. input terminals. Two d.c.

positive terminals and a single d.c. negative output terminal are provided.

The rectifier module may be operated as a 12-pulse network bridge. This configuration is achieved by

connecting the d.c. positive outputs together through an interbridge transformer and one a.c. input being

phase-shifted in relation to the other by an external supply transformer.

.png)

.png)

.png)