Woodward 723PLUS Digital Control

723PLUS Digital Control

9906-619. 9906-620. 9906-700

This manual describes the Woodward 723PLUS Digital Control hardware,

9906-619 (low voltage), 9906-620 (high voltage), and 9906-700 (modified

actuator filtering, low voltage).

Application

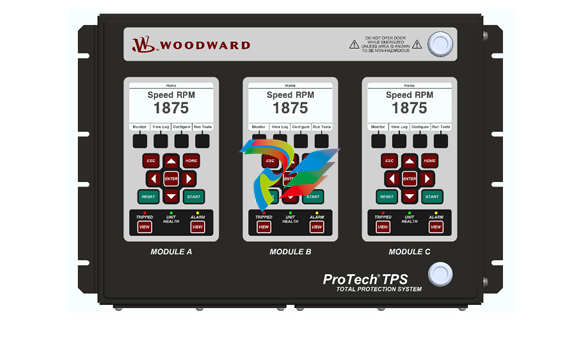

The 723PLUS Digital Control can be programmed to suit applications requiring

two magnetic pickups (MPUs) or proximity switches (e.g. for torsional filtering) as

the hardware includes two speed inputs. It also includes four analog inputs, three

analog outputs, eight discrete inputs and three discrete outputs, all of which can

be programmed to satisfy the application. The control can be used in load

sharing systems as it contains circuitry and connections to support this.

The two LON®* channels can be used to support Woodward LonTalk®* or

LinkNet® input/output nodes control functions.

*—LON and LonTalk are trademarks of Echelon Corporation.

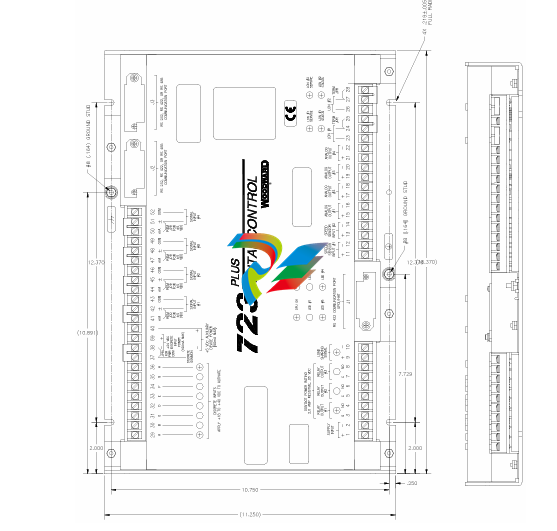

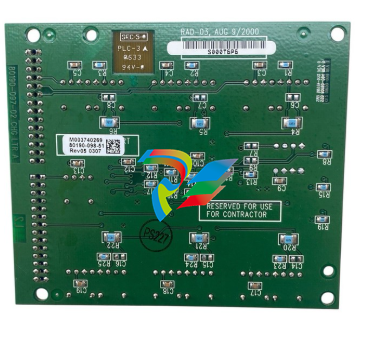

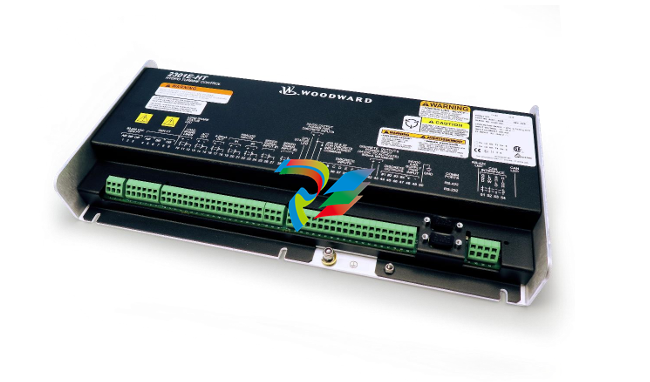

The 723PLUS control (Figure 1-1) consists of a single printed circuit board in a

sheet-metal chassis. Connections are via three terminal strips and three 9-pin

subminiature D connectors.

Control Options

The 723PLUS control requires the following power supply input voltages, with 40

watts as the nominal power consumption at rated voltage:

18–40 Vdc (24 or 32 Vdc nominal)

90–150 Vdc (125 Vdc nominal)

Discrete input voltages provide on/off command signals to the electronic control.

Each discrete input requires 10 mA at its 24 Vdc nominal voltage rating (for 24

volt switching logic).

Other control options are:

proximity switch input for speed signal frequencies below 100 Hz (see

NOTE)

0–1 mA for meter drivers

tandem actuator outputs

dual actuator outputs (0–200 mA)

The control may be used with either proximity switches (see NOTE) or magnetic

pickups. The minimum frequency for steady state speed control is 30 Hz. For

more information see Control Specifications (inside back cover).

723PLUS Digital Control Accessories

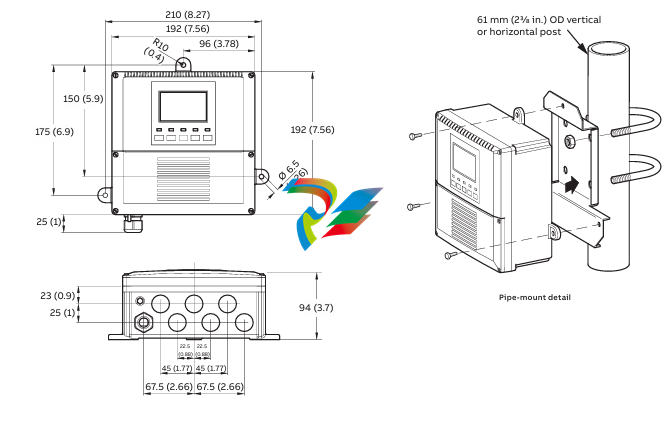

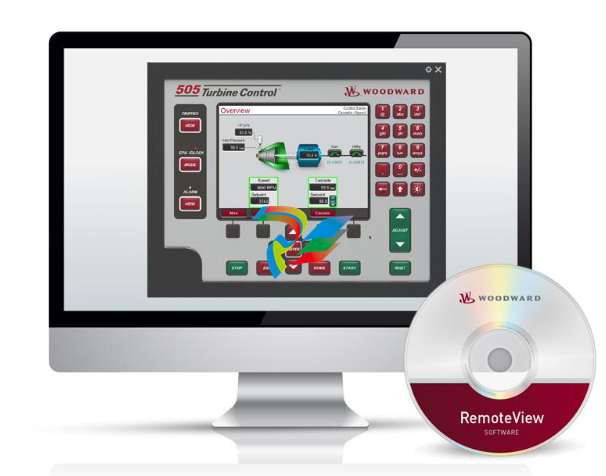

Hand Held Programmer (Figure 1-2), part number 9907-205. can be used

for adjusting the 723PLUS control. It plugs into serial port J1 of the control.

This part is EU Directive compliant.

SPM-A Synchronizer, for synchronizing the generator phase to that of the

power bus. The synchronizer generates a close generator breaker signal to

parallel the generator with the power bus.

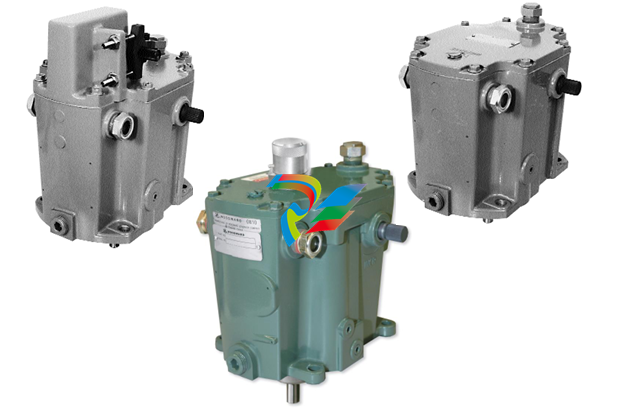

Power Output Sensor, for load sharing or droop operation in mechanical

load applications.

Real Power Sensor, for load sharing or droop-parallel generator

applications.

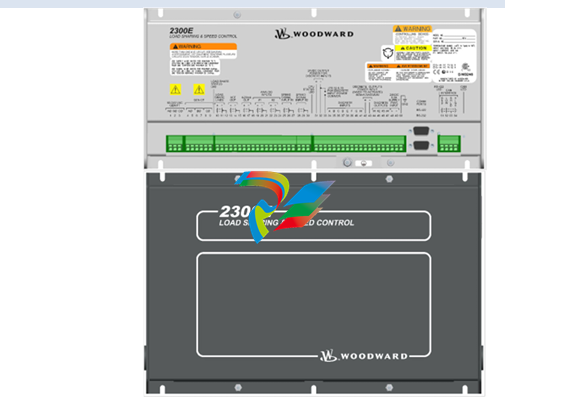

Digital Synchronizer and Load Control (DSLC™) for generator load

management.

Rack Position Sensor, for mechanical load sharing.

Load Pulse Unit, for improved system load transient response.

LinkNet nodes for additional input/output control functions.

Scope

This chapter contains general installation instructions for the 723PLUS control.

Power requirements, environmental precautions, and location considerations are

included to help you determine the best location for the control. Additional

information includes unpacking instructions, electrical connections, and

installation checkout procedures.

Unpacking

Before handling the control, read page v, Electrostatic Discharge Awareness. Be

careful when unpacking the electronic control. Check the control for signs of

damage such as bent panels, scratches, and loose or broken parts. If any

damage is found, immediately notify the shipper.

Power Requirements

The high-voltage versions of the 723PLUS Digital Speed Control require a

voltage source of 90 to 150 Vdc. The low-voltage versions require a voltage

source of 18 to 40 Vdc

Location Considerations

Consider these requirements when selecting the mounting location:

adequate ventilation for cooling

space for servicing and repair

protection from direct exposure to water or to a condensation-prone

environment

protection from high-voltage or high-current devices, or devices which

produce electromagnetic interference in excess of levels defined in

EN50082–2

avoidance of vibration

selection of a location that will provide an operating temperature range of

40 to +70 °C (–40 to +158 °F)

Specific Marine Installation Requirements

Marine Type approval requirements change over time. In recent years, there has

been at least the addition of a stricter emission limit. A 156–165 MHz band notch

has been added and referred to here as the “Marine Notch”. To address the

Marine Notch, additional installation limitations are required for new installations

under the updated Marine Type approvals.

All wiring, except for the last 12 inches (305 mm) adjacent to the control

connection terminals must be inside a metal conduit, metal cable armoring,

enclosed metal cable way, or similar metal acting as a secondary shield. The

metal acting as the secondary shield must be grounded to the same reference

ground as the control chassis. In some cases, the chassis reference ground is

also referred to as Protective Earth (PE). All wiring must also follow the wiring

and shielding requirements given in the specific, separate software manual.

The control must be mounted on a metal mounting plate that is grounded to the

same reference ground potential as the control’s chassis.

Alternatively, if the installation is limited to areas of the ship where at least 6 dB

.png)

.png)