Woodward 723PLUS Digital Control

attenuation of the RF signals from the control can be guaranteed, no additional

special measures are needed. The signals in the 156–165 MHz range must be

attenuated by 6 dB before they reach the receiver antenna or receiver

(interference point), and the control must be >3 m away from the antenna or

receiver. This is a specific installation dependency, and some examples may

include:

A grounded, metal, IP rated cabinet with all cabling staying inside it for more

than 2 m length, with any shield terminations at the cabinet exit/entry point

and all unshielded cable routed directly against the metal cabinet.

A below-deck metal engine room where none of the cabling, including power,

leaves the engine room.

If using a specific installation location or method as a means to meet the Marine

Notch requirements, instead of a secondary metal shield for cabling, consult the

ship builder. Acceptability of the installation for obtaining 6 dB of RF attenuation

in the 156–165 MHz range must be provided by the ship builder. Woodward will

not know the ship installation application or requirements to provide guidance.

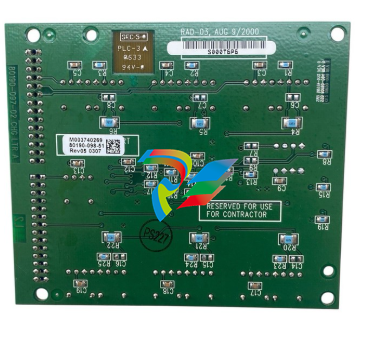

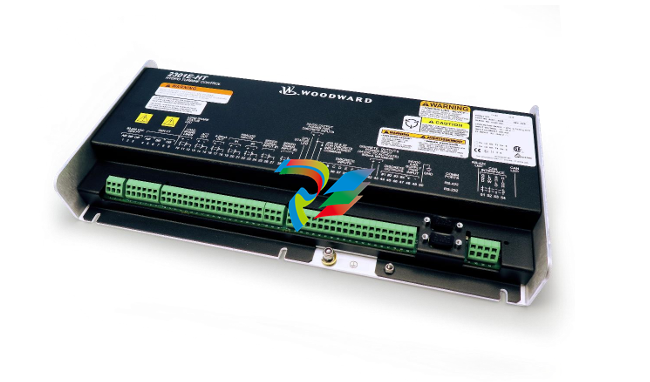

Internal Jumpers

The 723PLUS control has ten, two-position internal jumpers (JPR1 through

JPR20) located on the top of the printed circuit board. If it is necessary to change

any jumper to match your control requirements, and this suits the nature of the

software, be sure to read page v, Electrostatic Discharge Awareness.

Remove power and all inputs. Wait 45 seconds, then remove cover. With your

fingers or a small pair of tweezers, carefully remove the appropriate jumper and

replace it securely over the proper two connectors (see Figure 2-1).

Notes for Figure 2-2

Shielded wires are twisted pairs, with shield grounded at one end only. When

mounting control to bulkhead, use the grounding stud and hardware supplied with

the chassis to ensure proper grounding.

Shields must not be grounded at any external point unless otherwise noted.

All shields must be carried continuously through all terminal blocks and must not be

tied to other shields except at the common ground point. Tie all shields together at

ground stud located near connector J1.

Remove jumper for voltage input.

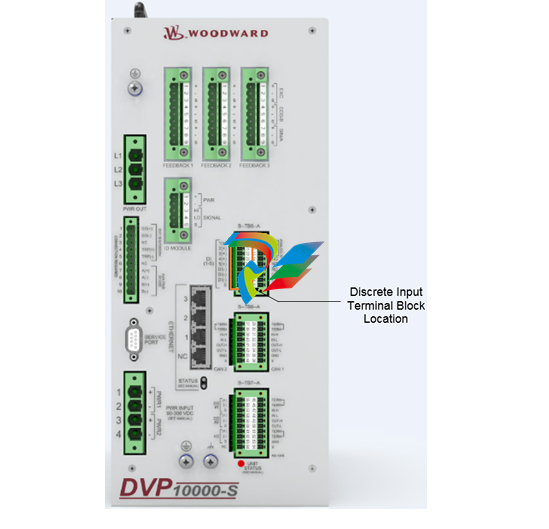

Remove jumper if using external discrete input power.

Discrete inputs are isolated from other circuits and intended to be powered by

TB1-39 (+24) leaving the jumper in place. Input current is nominally 10 mA input into

2210 Ω.

7. Unless otherwise specified:

A. Relays shown de-energized

B. Relays energize for function

C. Relay contact ratings for minimum 100 000 operations:

Resistive— 2.0 A at 28 Vdc

0.1 A at 115 Vac 50 to 400 Hz

Inductive— 0.75 A at 28 Vdc 0.2 Henry

0.1 A at 28 Vdc lamp

Analog output signals to other systems must be isolated from ground either by

design or employment of isolation amplifiers.

Analog input signals to other systems must be isolated from ground either by design

or employment of isolation amplifiers.

10. Factory set for MPU input.

11. Factory set for 20–160 mA output.

12. Factory set for 4–20 mA output.

13. Internal power supply provides dc isolation between the power source and all other

inputs and outputs.

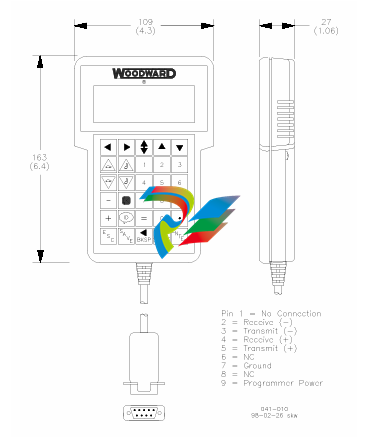

14. Communication port J1 can be used with the Woodward ST2000 Hand Held

Programmer or PC Interface using Watch Window/Servlink software.

15. Communication port J2 or J3 can be configured as an RS-232. RS-422. or RS-485

serial interface. Port configuration can be done in the application software only. For

the pin assignment of J2 and J3. see later in this chapter.

16. This analog output may connect to a metering/controlling device. The shield should

be continuous between all connected devices with a single shield termination point to

ground.

17. Use twisted pair shielded wires only.

18. Remove jumper if used with the gas engine I/O node.

Termination is accomplished using a three-resistor voltage divider between a

positive voltage and ground. The impedance of the resistor network should be

equal to the characteristic impedance of the cable. This is usually about 100 to

120 ohms. The purpose is to maintain a voltage level between the two differential

lines so that the receiver will be in a stable condition. The differential voltage can

range between 0.2 and 6 volts; but the maximum voltage between either receiver

input and circuit ground must be less than 10 volts. There is one termination

resistor network for each port located on the 723PLUS board. Connection to this

resistor network is made through the 9-pin connectors on pins 6 and 9. See

Figures 2-5 through 2-8 for termination and cable connection examples.

Due to the variety of installations, plus system and component tolerances, the

723PLUS control must be tuned to each system for optimum performance.

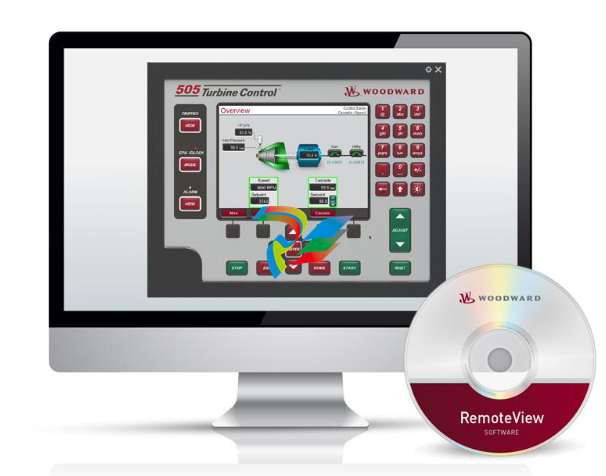

This chapter contains information on how to enter control set points through the

control's menu system using the Hand Held Programmer. If you have access to

the Watch Window software tool and Servlink software, you can set up and tune

the 723PLUS control from a PC (personal computer) using the instructions in

Chapter 5 of this manual.

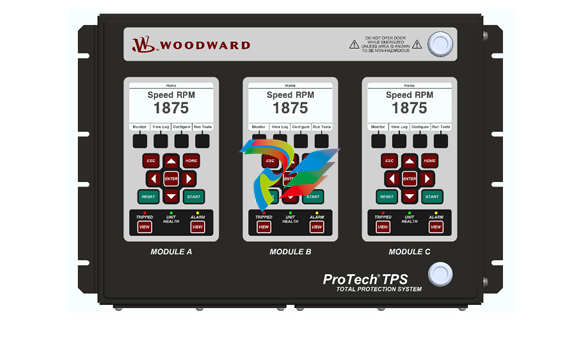

Hand Held Programmer and Menus

The Hand Held Programmer is a hand-held computer terminal that gets its power

from the 723PLUS control. The terminal connects to the RS-422 communication

.png)

.png)