Woodward 85018V2 505E Digital Governor for Extraction Steam Turbines

and should be used to sense generator power output. Many different real power

sensors of this type exist. Some of the optional RPS features include VAR

sensing, Loadsharing, 0–1 A CT current sensing, and multiple combinations of

these. Please consult a Woodward certified distributor or a Woodward factory for

the recommended RPS for your application.

The second type of RPS manufactured by Woodward is designed to sense

power flow through a bus-to-bus tie line. This RPS (8272-726) senses –5A to

+5A CT current to allow its output to represent power flow in both directions. This

RPS provides a 4–20 mA power indication output signal where 12 mA represents

0 power flow. It is recommended that this RPS be used to sense power flow

through a tie line only. This RPS or equivalent is required to sense plant Import

and Export power.

Woodward Real Power Sensors have terminals labeled “Output” and terminals

labeled “KW Readout”. The “KW Readout” terminals provide a 4–20 mA signal

proportional to real power which is used by and compatible with the 505E control.

Thus the RPS terminals labeled “Output” are designed and typically compatible

only to Woodward’s 2301 type of control

Woodward manufactured Real Power Sensors have a 2.5 Hz Low pass filter (400

ms lag time) on their output to filter out the high frequency noise typically created

in a switch gear type environment. Thus if another vendor’s watt transducer is

used, verification that it has similar filtering criteria should be performed before it

is applied with the 505E. For more information on Woodward Real Power

Sensors, please refer to Woodward manual 82018.

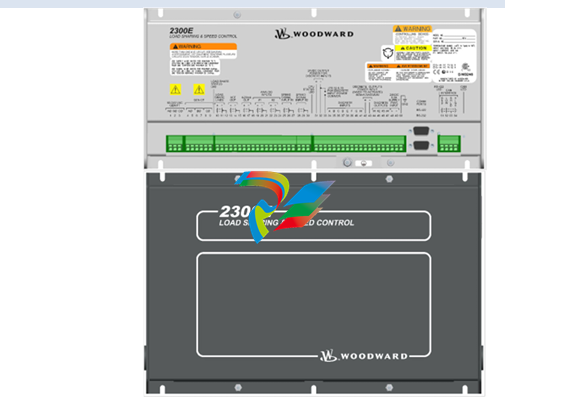

Digital Synchronizer and Load Control (DSLC™)

The Woodward DSLC™ is a microprocessor based generator load control

designed for use on three-phase AC generators with Woodward speed controls

and automatic voltage regulators. The DSLC is a synchronizer, a load control, a

dead bus closing system, a VAR/PF control, and a process control, integrated

into one package.

The 505E can be programmed to use the DSLC as a synchronizer only, or as a

synchronizer and load control. The DSLC provides either phase match or slip

frequency synchronizing, and ties into the unit automatic voltage regulator to

match voltages before paralleling. It interfaces with the 505E via a Speed bias

signal to control generator frequency and phase. When configured to use the

DSLC as a synchronizer only, the 505E must be programmed to receive the

DSLC Speed Bias signal through an analog input and have this input enabled

through a contact input or function key.

The DSLC communicates over a LAN using a digital Echelon network with other

system DSLCs to enable it to perform safe deadbus closings. Because the DSLC

performs all synchronizing functions simultaneously, synchronization typically

takes only a few seconds.

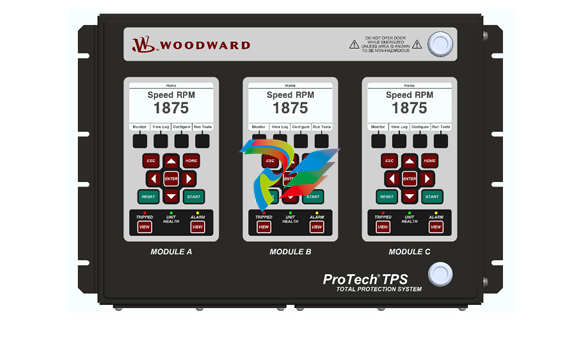

When used as a synchronizer and load control, the DSLC performs automatic

synchronization, and controls unit load based on the DSLCs mode of operation.

The DSLC can be in a base-load, loadsharing, remote load setting, or Process

control mode, depending on configuration and system conditions.

The DSLC’s baseload mode of operation allows an operator to set the unit to a

specified load. A proportional or integrating control action can be used with this

mode of operation. The integrating mode of operation can be used with systems

tying to an unstable grid to allow the unit to control at a constant load and not

vary based on grid frequency.

The DSLC’s loadsharing mode is used to share load with any other units using a

DSLC and tied to the same isolated bus. This mode is used in conjunction with a

Master Synchronizer & Load Control when paralleled to a utility to allow the

MSLC to control plant frequency or load depending on its state of operation.

The DSLC’s remote load setting mode allows load to be set by a remote 4–20

mA signal. The DSLC’s Process control mode allows any process directly related

to generator load to be controlled.

When using the DSLC as both a synchronizer and load control, the 505E control

must be programmed to receive the DSLC Speed Bias signal through an analog

input and have this input enabled through a contact input or function key.

After synchronization, unit load can be controlled by the DSLC (through the 505E

Sync/Ld input) or by the 505E’s internal speed/load setpoint. When the Sync/Ld

Share input is programmed, the position of the Utility Tie Breaker Contact selects

unit load control through the DSLC or through the 505E’s internal load setpoint.

The DSLC interfaces to the 505E via a Speed Bias signal. From the many

different types of DSLCs manufactured by Woodward only a few have a Speed

Bias output (1–5 Vdc) compatible with the 505E control. The 505E’s isolated

analog #6 input is the only analog input that is directly compatible with the DSLC.

Thus the DSLC’s speed bias output should only be connected to the # 6 analog

input. The DSLC’s speed bias output is designed to drive into the 505E’s low

impedance input.

Once the generator is synchronized the DSLC soft-loads the unit to the load

setting determined by the mode of operation (base load, loadsharing, Process

control). When commanded the DSLC can also soft-unload the unit and issue a

.png)

.png)