ABB Ability™ Symphony® Plus HR Series Control and I/O

2.HR Series controller features include: • Enhanced controller reliability • More than 10x performance of previous generation controllers • Simultaneous support for all HR Series I/O, SD Series I/O and S800 I/O subsystems • Intelligent device integration via HART I/O and PROFIBUS DP V0, V1, V2 • Downloadable firmware • BRC400 / BRC410 specific enhancements: – Extended user configuration memory (2 MB NVRAM) – Support for 30,000 function blocks – Flexible online configuration capability – Modbus TCP device integration via 100 MB Ethernet port (BRC410 only)

3.High reliability and availability With redundant controller, communication, I/O and power options such as the recently released MPS IV (Modular Power System), HR Series controller subsystems provide the highest level of availability. Compliance with international standards assures the highest level of reliability and quality needed to meet the most rigorous global specifications and requirements. Backward compatibility through ABB’s ‘Evolution without obsolescence’ life cycle program ensures protection of installed investments while providing the most cost-effective and seamless way of introducing new functions and technology into a running plant. Together, the HR Series provides users with fast, accurate, uninterrupted control of their process, resulting in greater production efficiency, increased availability, and lower maintenance costs.

4.Soft controller reduces commissioning times For new plant, upgrade, or expansion projects, HR Series soft controllers can dramatically reduce commissioning and start-up time and costs by permitting thorough testing and pre-tuning of control loops prior to its implementation in the field. The HR Series soft controller uses the same control logic (ie, function block configuration) as the physical HR Series controllers. Coupled with virtual communication devices, the entire HR Series control-based system can be implemented within one or more PCs which allow for testing results made in the virtual environment to be directly transferable to the operating system environment.

1.Comprehensive I/O product portfolio S+ I/O, available for local and remote mounting, provides a wide variety of input/output and signal conditioning capabilities. In combination, these rack and DIN I/O modules can be combined to form the optimal automation solution

2.HR Series controllers can communicate with up to 64 rack I/O modules locally with additional remote rack I/O modules connected via the RIO22 module. Use of rack sequence of events (SOE) I/O modules provides one millisecond timestamp resolution across the entire rack system

3.HR Series I/O module types include:

• Analog input (ASI, FEC)

• Analog output (ASO)

• Control input/output (CIS, QRS)

• Digital input (DSI)

• Digital output (DSO)

• Pulse input (DSM)

• SOE digital input (SED)

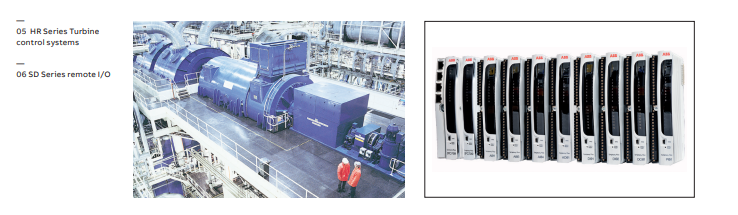

4.Turbine control In addition to traditional signal-type I/O, HR Series provides for integrated turbine control via a series of turbine control-specific modules, including: • Hydraulic servo module (HSS) • Turbine protection module (TPS) • Turbine auto synchronization module (TAS) • Condition monitoring module (CMM)

5.These unique modules make it possible to provide a fully integrated single-vendor solution for all aspects of turbine automation. HR Series turbine modules are based on proven technology that controls steam turbines, gas turbines and hydroelectric turbines in more than 15 different countries around the world, and have been tested, accepted, and used by several major global turbine manufacturers as part of their standard offering. The combination of HR Series controllers and turbine I/O results in a powerful governor control system solution.

6.SD Series remote I/O option HR Series remote I/O capabilities are further expanded with use of the SD Series DIN rail mounted I/O products. Compatible with all HR Series controllers, BRC300 / 400 / 410, SD Series I/O connects directly to the controller via the HN800 I/O network without the need for an intermediate interface or gateway. SD Series I/O is configured using standard function blocks and includes traditional analog and digital I/O as well as integration with intelligent field devices via PROFIBUS DP and HART. 24 VDC power requirements, low module power consumption, and a module temperature rating of 70 DEGC (ambient) makes SD Series I/O the optimal choice for remote I/O applications. G3 coating makes SD Series I/O suitable for use in corrosive environments without requiring costly sealed cabinets or purging systems.

HR Series Integrating field devices seamlessly

1.Device integration capability In today’s power generation and process industries, only about 10% of field instruments have a digital pathway back to the control system. This reduces smart devices to underutilized assets where the existing diagnostic and connection information residing in the field instruments is not utilized in system operations.

2.The HR Series seamlessly integrates intelligent field devices and protocols using PROFIBUS DP, HART, and Modbus TCP and RTU. This provides access to a wide range of intelligent field devices from both ABB and other third-party vendors including transmitters, actuators, motor control centers (MCC) and flame scanners. Each device’s resident information can then be used in control strategies and higher level applications. In addition to producing tighter and more reliable process control solutions, these solutions lower installation costs by reducing wiring and system footprint.

.png)

.png)

.png)