ABB Ability™ Symphony® Plus HR Series Control and I/O

3.Intelligent Hart I/O HR Series controllers seamlessly integrate HART field devices through a variety of SD Series HART analog input and output modules. Besides the 4-20 mA primary variable, all secondary, tertiary and quaternary variables in a HART device can be accessed by Function Code control applications in the HR Series controller. Data can be calculated, used as part of a control strategy, or for display and alarm purposes at the system's HMI console

4.SD Series HART I/O features include:

• Each channel’s secondary/tertiary/quaternary variables are available for use in control applications

• Update rate of secondary/tertiary/quaternary variables is less than one second (AI05 and AO05)

HR Series Securing your control investments

1.Protecting the integrity and confidentiality of system data The process and power industries face intensifying cyber security risks. In order to increase stability, security and robustness in its solutions, ABB has established an independent Device Security Assurance Center (DSAC) where cyber security robustness is tested as part of the product development process. The DSAC test facility uses state-of-the-art open source, commercial and proprietary robustness and vulnerability analysis tools. All Symphony Plus Ethernet-based devices - including HR Series products such as the BRC410, ICI800, and IEB800 - are continually tested at the DSAC center in different configurations and with an explicit focus on operational performance. This ensures that all Symphony Plus products are robust, secure and of the highest quality

2.Seamless upgrade path protects investments True to ABB’s ‘Evolution without obsolescence’ commitment, HR Series products provide backward compatibility to previous generation Network 90, INFI 90, INFI 90 Open and Harmony hardware and software, including support for existing function code executions, custom user programs, and all foreign device interfaces. ABB's 'Evolution without obsolescence' ensures the protection of installed investments while providing the most predictable, cost-effective, risk-averse, and seamless way of introducing new functions and technology into a running plant.

3.Specifically, HR Series products:

• Replace previous generation rack products on a form/fit/function basis

• Preserve installed I/O through simultaneous connection to HR Series I/O, previous generation rack and block I/O, SD Series I/O and S800 I/O

• Use the same field-proven INFI 90 function code algorithms as previous generation controllers (ie, MFCxx and MFPxx controllers)

• Enhance existing Composer engineering tools with device management capabilities

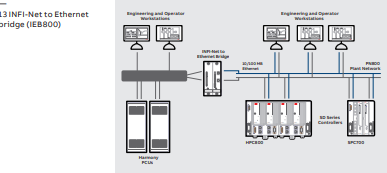

4.Further, HR Series and SD Series control networks, INFI-Net and PN800 (INFI-Net over Ethernet) respectively can be connected via a self-configuring INFI-Net to Ethernet bridge (IEB800 module). This allows for the easy expansion of existing INFI-Net communication networks with INFI-Net on Ethernet technology and SD Series DIN rail mounted products. Additionally, resident data from either network is available for use in control applications or for display in applications connected to the other.

HR Series Efficient engineering tools for design and maintenance

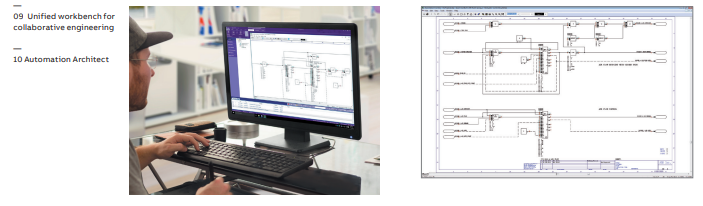

1.Robust – efficient – comprehensive S+ Engineering is the comprehensive engineering tool set for HR Series based systems. The unified workbench offers all the necessary functionality needed to engineer, configure, administrate, secure, commission and maintain every component in your Symphony Plus Control System - from control and I/O, field instrumentation and electrical devices to network architecture, and operations, engineering, and advanced system applications.

2.Integrated control engineering S+ Engineering allows for easy reuse and upgrade of previous generation Symphony, INFI 90 OPEN, INFI 90, and Network 90 control applications. In addition, the extensive reuse concept of S+ Engineering allows users to optimize plant design with field-proven solutions based on ABB’s in-depth experience in the power and water industries.

3.S+ Engineering’s seamless tool integration, powerful workflow automation, multi-user and remote access capabilities and comprehensive bulk import/export functions improve overall engineering efficiency. Integrated version control, version comparison and rollback framework offer progress tracking and significantly reduce commissioning time. Using intelligent bulk interfaces, S+ Engineering allows for full control of engineering data consistency in each phase of the project life cycle.

4.S+ Engineering’s Automation Architect provides for visual creation, editing, monitoring and tuning of control logic. Rather than textually programming strategies, the Automation Architect represents pre-defined control strategies as function blocks. By connecting function blocks, users are able to easily specify the signal flow of a control strategy and visually define the control strategy. Monitoring and tuning capabilities provide the ability to troubleshoot and maintain an operational system using the same information used to create the system

.png)

.png)

.png)