ABB Ability™ Symphony® Plus HR Series Control and I/O

5.Secure user management The simple and intuitive workbench interface allows engineers to configure user information for the Windows and Engineering databases. It allows and secures the creation of user profiles along with their roles and project access permissions through Role Based Access Control (RBAC). Audit trail functionality tracks and archives user actions including system changes made at any engineering workstation onto a central database. These events can then be archived in the system’s historian for long term security audit purposes.

6.In addition to function blocks, S+ Engineering supports batch or sequential programming via the Batch Data Manager (BDM). BDM is a family of engineering tools used for creating, editing, managing, downloading, and debugging Batch 90, sequential, and user-defined function code configurations.

1.Reusable standard solutions S+ Engineering improves the quality of control strategy software by minimizing the risk of errors of starting from scratch. S+ Engineering allows users to define and maintain their field proven control logic through the use of it Control Logic Templates (CLT) and Configurable Function Codes (CFC).

2.CLTs are thought of as control strategy blueprints. Its linking functionality allows users to define logic that is controlled by the template or can be modified on each configured instance. Any subsequent changes made to a template can be propagated to all linked instances.

3.CFCs allow engineers to create specific control logic using standard Harmony function codes and then save it as a package which can then be used as a standard Harmony function code in control logic design. This simplifies the control logic design and documentation by eliminating the need to re-write the entire CFC logic contents in every instance it is used in the control scheme. The CFC can be represented by a custom shape, control logic, defined inputs, defined outputs, defined specifications and tag mapping. Black box options secure user intellectual investments in their control solutions.

4.Device management HART and PROFIBUS devices are fully integrated with Symphony Plus, yielding benefits far beyond reduced footprint and cable costs. The engineering suite supports configuration, commissioning and maintenance of HART and PROFIBUS devices using device type manager (DTM) technology. For field devices that have conventional device description files (GSD), a basic PROFIBUS DTM is available to allow standardized configuration. HART devices are integrated, configured and parameterized via standard HART protocol without the need for additional tools by using a standard HART DTM. Individual DTMs can be accessed from the engineering tool’s multiple data views, such as the system or location overview and others. S+ Engineering includes automatic net calculation and loading of process items by using the device specific channel configuration generated from the DTM.

5.On-line features allow for proactive device monitoring and notification of problems with quick access to device alerts and high priority conditions. A built-in web view provides a Device Status Dashboard, as well as an Event Viewer and Device Details pages, allow for quick drill-down to identify device root problems and corresponding resolution. This enables to users to take decisive action to increase plant reliability while lowering maintenance costs.

HR Series Field tested, field proven

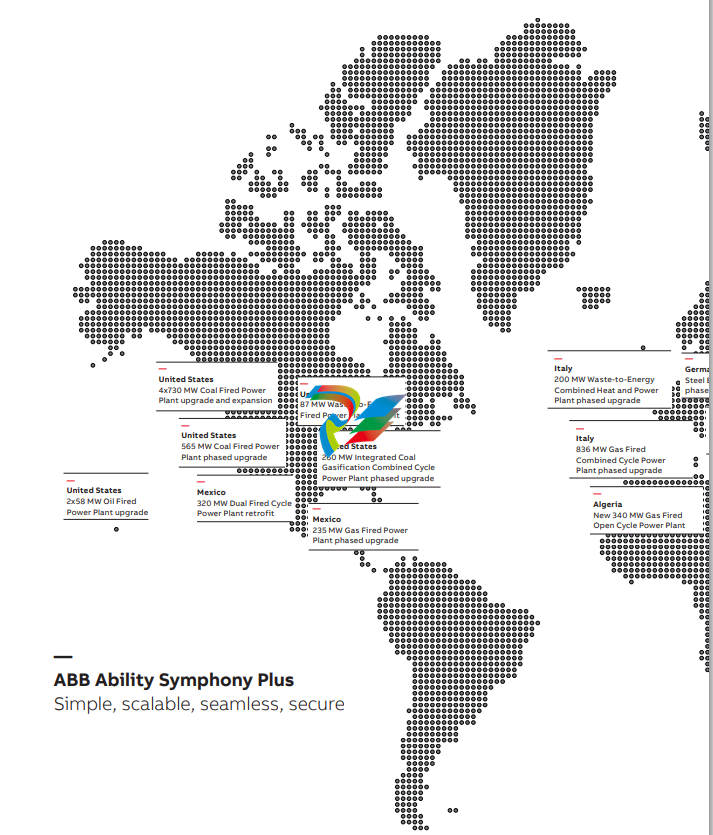

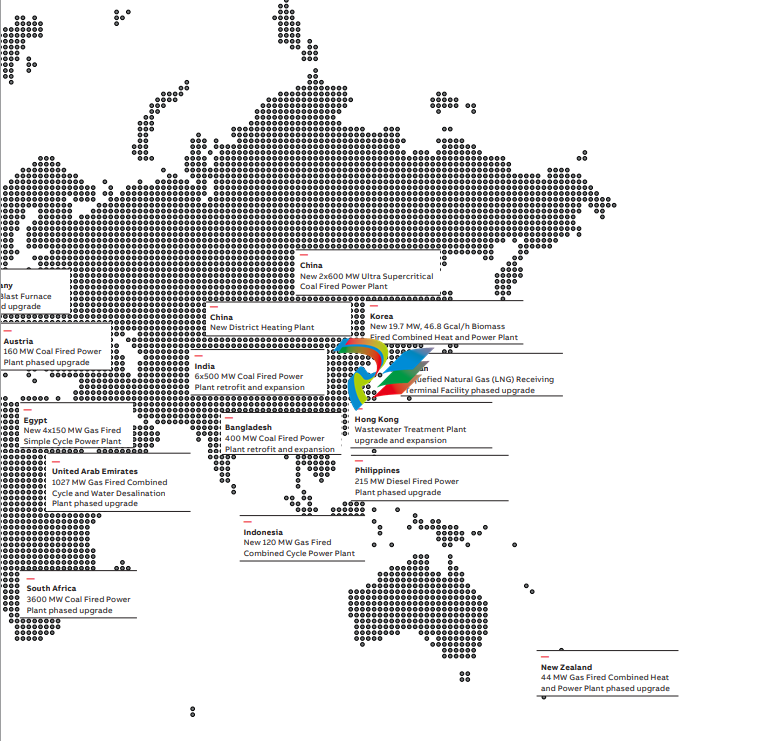

Since its introduction in 2011, ABB has delivered or is delivering Symphony Plus solutions that control more than 70,000 MW of additional power generation. These solutions range in complexity from the simplest to the most challenging of automation requirements, and for power and water facilities of all sizes. Below is a sample of the breadth of Symphony Plus HR Series based solutions selected for power generation and water from installations around the world.

.png)

.png)

.png)