MOOGUser Manual M3000® Automation System MSC II (Moog Servo Controller)

1 General Information

1.1 About this Manual

This manual is valid only for the M3000 About this Manual ® automation system and M3000®

modules. It contains most important instructions that must be observed in order to operate the M3000® automation system and M3000® modules in a

safe manner.

Every person responsible for machinery planning, mounting, and operation

must read, understand, and follow all points covered in this manual. This applies especially to the safety instructions. Following the safety instructions

helps to avoid accidents, faults, and material damage!

Using M3000® Safely

(Prerequisites)

The following items must be observed as fundamental elements of safety

when using the M3000® automation system and M3000® modules:

• All safety instructions contained in this manual

• All safety instructions contained in the documentation of the M3000®

modules

• All safety instructions contained in the product related hardware and

software documentation required for the relevant application

• All relevant nationally and internationally applicable safety and accident

prevention regulations and standards

1.1.1 Reservation of Changes and Validity

Reservation of Changes

and Validity for this

Manual

The information contained in this manual is valid at the time of this version's

release. See footer for version number and release date of this manual.

Moog reserves the right to make changes to this manual at any time without

specified reasons.

1.1.2 Exclusion of Liability

This manual was prepared with great care and the contents reflect the authors' best knowledge. However, the possibility of error remains and improvements are possible.

Please feel free to submit any comments regarding errors or incomplete information to Moog.

Exclusion of Liability for

this Manual

Moog does not offer any guarantee that the contents conform to applicable

legal regulations nor does Moog accept any liability for incorrect or incomplete information and the consequences thereof.

1.1.3 Completeness

Completeness of this

Manual

This manual is complete only when used in conjunction with the product related hardware and software documentation required for the relevant application.

1.1.4 Place of Storage

Place of Storage

for this Manual

This manual and all other associated documentation for hardware and software must always be kept in a location where they will be readily accessible

and close to the M3000® automation system and M3000® modules or the

equipment in which they are installed

1.2 Selection and Qualification of Personnel

Only qualified users may work with and on the M3000 Qualified Users ® automation system or M3000® modules.

Qualified users are properly trained experts with the required knowledge and

experience. In particular, these experts must have the authorization to bring

into operation, ground, and label devices, systems, and power circuits in accordance with safety engineering standards. Those people working on a

project must be familiar with safety concepts common in automation.

1.3 Proper Use

The M3000 Proper Use ® modular automation system is suitable for control applications in

the medium to high end performance ranges.

M3000® is designed for use within the overvoltage category defined by

IEC 60364-4-44 for controlling machines and industrial processes in low voltage systems in which the rated supply voltage does not exceed 1,000 V alternating current (50/60 Hz) or 1,500 V direct current.

Qualified project planning and design, proper transportation, storage, installation, and use are required to ensure fault-free, reliable, and safe operation of

M3000®.

M3000® and M3000® modules must not be brought into operation until it has

been ensured that the equipment in which they are installed complies with the

current version of the EU machinery directive.

The M3000® automation system and M3000® modules may be used only under the conditions and situations specified in this manual and in the documentation of the M3000® modules.

Any other or more extensive use is not permissible.

The following are also required for proper use:

• Compliance with the requirements detailed in this manual

• Compliance with the requirements of individual M3000® module documentation

• Compliance with all of the product related hardware and software documentation required for the relevant application

• Compliance with the relevant nationally and internationally applicable

regulations, standards, and directives, e.g., the regulations specified by

a professional organization, such as TÜV or VDE

1.3.1 Safety Related Systems

Safety Related Systems

Special measures are required to use control technology in safety related

systems.

When planning to use control technology in a safety related system, the user

should seek detailed advice in addition to any available standards or guidelines for safety installations.

WARNING As with any electronic automation system, the failure of

certain components when using M3000® or M3000® modules might lead to an uncontrolled and/or unpredictable

operational condition. The user should take into consideration the system level effects of all types of failures

and implement corresponding safety measures.

1.4 Warranty and Liability

Moog's standard delivery and payment conditions apply. The owner/operator

will have access to these by the time the contract is closed at the latest.

Exclusion of Warranty and

Liability

Warranty and liability claims for personal and material damage will be excluded when they are the result of the following, among others:

• Improper use of the M3000® automation system or M3000® modules

Ö-"1.3-Proper Use" on page 2

• Use of the M3000® automation system or M3000® modules

in a technically imperfect condition

• Use of the M3000® automation system or M3000® modules

by unqualified users

Ö-"1.2-Selection and Qualification of Personnel" on page 2

• Failure to comply with this manual, the documentation of the

M3000®-modules, or the product related hardware and software

documentation required for the relevant application

• Failure to comply with the relevant nationally and internationally

applicable regulations such as the regulations of a professional

association, the TÜV, or the VDE

• Improper deployment of the M3000® automation system or

M3000®-modules, such as in a potentially explosive, excessively

warm, or excessively cold environment

• Improper storage, transportation, mounting, removing, connection,

bringing into operation, operation, cleaning, or maintenance of the

M3000® automation system or M3000® modules

• Storage or transportation of M3000® modules or accessories

outside of the original packaging

Ö-"9-Transportation and Storage" on page 71

• Unauthorized or improperly executed structural changes to the

M3000® automation system or M3000® modules

• Unauthorized or improperly executed repairs on the M3000® automation

system or M3000® modules

Ö-"8.2.2-Repair" on page 70

• Damage due to the intrusion of foreign objects or acts of God.

1.5 Inspection of Delivery

After receiving the delivery, please check the original packaging and its con- Inspection of Delivery

tents for any damage.

If the packaging or contents exhibit any damage, do not bring the items into

operation. In this case, immediately notify Moog or the responsible supplier.

In addition, the packaging should be retained. The packaging might be

needed to enforce damage compensation claims on the transport company.

After taking the delivery, please check whether all items listed on the delivery

docket are present. If anything is missing, immediately notify Moog or the responsible supplier.

Retain the Original

Packaging

It is advisable to retain the original packaging for any future transport or storage needs.

1.6 Environmental Protection

1.6.1 Emissions

Environmental Protection:

Emissions

M3000® modules do not have any harmful emissions when used properly.

1.6.2 Disposal

Environmental Protection:

Disposal

1.7 Standards

1.7.1 CE Labeling of M3000® Modules

CE Labeling of M3000®

Modules

1.7.2 IEC 61131-2

M3000® and M3000®

Modules Comply with

IEC 61131-2

The M3000® automation system and M3000® modules comply with the requirements of IEC 61131-2.

1.7.3 Electromagnetic Compatibility (EMC)

Electromagnetic

Compatibility (EMC)

M3000® modules comply with the requirements and protection targets of the

EU directive 89/336/EEC “Electromagnetic Compatibility” (EMC directive)

and comply with the harmonized European standards (EN) that were published in the Official Journals of the European Union for programmable controllers.

Especially important are the rules for proper EMC wiring in cabinets and

buildings according to IEC 61131-4. Installation in metal, grounded cabinets

is preferred.

M3000® modules are designed for use under normal operating conditions in

industrial environments and comply with the following standards:

• DIN EN 61000-6-2

• DIN EN 61000-6-4

If suitable additional measures are taken, M3000® modules may also be employed in residential, commercial and light-industrial environments in compliance with the following standards:

• DIN EN 61000-6-1

• DIN EN 61000-6-3

Suitable additional measures:

Ö-"4.2-Use in Special Environments" on page 28

The applicable disposal regulations must be observed when disposing of

M3000® modules!

All M3000® modules comply with the standards specified in

their relevant declaration of conformity.

CE labeling of the M3000® modules is based on proper installation of the automation system with proven electromagnetic compatibility (EMC).

Where technical requirements lead to deviations from the standard,

these are specified in this manual or in the documentation of the relevant

M3000® modules

If the system does not comply with the requirements of DIN EN 61000-6-1

and DIN EN 61000-6-3, despite the additional measures, M3000® modules

must not be used in residential, commercial and light-industrial environments.

EMC conformity may be presumed only under the following conditions:

• Sufficient shielding

• Mounting of the DIN rail module onto a DIN top-hat rail that is attached to

an electrically conductive, grounded mounting plate

Ö figure-17 on page 31

MSC II and extension modules must be powered from a power supply with

SELV (Safety Extra-Low Voltage) according to DIN EN 60950-1. Therefore

the EU low voltage directive is not relevant for the M3000® automation system because the specified voltage levels lie below the limits.

1.8 Trademarks

Moog and Moog Authentic Repair are registered trademarks of Moog Inc. Trademarks

and its subsidiaries.

M3000® is a trademark of Moog GmbH that is registered in the EU.

1.9 Software Copyrights

The software that is installed on M3000 Software Copyrights ® products at the time of delivery is

the property of the manufacturer. At the time of delivery, every piece of installed software is covered by copyright protection. It may be reproduced only

with the approval of the manufacturer or in accordance with the license

agreements.

All product and company names mentioned in this manual might be protected trademarks or brands of the relevant manufacturer.

The absence of the symbols ® or ™ does not indicate that the name is

2 Safety Instructions

This chapter summarizes the most important safety instructions. When handling the M3000® automation system or M3000® modules the safety instructions in the other chapters of this manual must be followed as well as the

safety instructions in the product related hardware and software documentation required for the specific application.

Following the safety instructions helps to avoid accidents, faults, and

material damage!

2.1 Typographical Conventions

Safety Instructions:

Typographical

Conventions

The following symbols and styles are used for identifying the different types of

safety instructions:

Additional typographical conventions:

Ö-"12.1-Typographical Conventions" on page 124

2.2 Safety Instructions

2.2.1 Safety Related Systems

Safety Instructions: Safety

Related Systems

More on this subject: Ö-"1.3.1-Safety Related Systems" on page 2

DANGER Identifies safety instructions that are intended to warn of

an immediate and impending danger to life and limb or

major property damage.

Failure to observe these safety instructions will lead inevitably to death, serious personal injury (disablement)

or major property damage!

WARNING Identifies safety instructions that are intended to warn of

potential danger to life and limb or the potential for major property damage.

Failure to observe these safety instructions might lead

to death, serious personal injury (disablement) or major

property damage!

CAUTION Identifies safety instructions that are intended to warn of

slight personal injury or minor property damage.

Failure to observe these safety instructions might lead to

slight personal injury or minor property damage.

As with any electronic automation system, the failure of

certain components when using M3000® or M3000® modules might lead to an uncontrolled and/or unpredictable

operational condition. The user should take into consideration the system level effects of all types of failures

and implement corresponding safety measures

2.2.2 Environmental Conditions

Safety Instructions:

Environmental Conditions

More on this subject:

Ö-"4-Environmental Conditions" on page 27

Ö-"10.2.2-Environmental Conditions" on page 74

2.2.3 ESD

Safety Instructions: ESD

WARNING Maintain under all circumstances the required environmental conditions specified for the M3000® automation

system or M3000® modules.

This ensures fault-free, reliable, and safe operation.

WARNING The PC on which tools such as MACS development environment are installed must be suitable for the environmental conditions in which it will operate.

This ensures fault-free, reliable, and safe operation.

WARNING It is not permissible to operate the M3000® automation

system or M3000® modules in a potentially explosive

environment.

WARNING The M3000® automation system and M3000® modules

must not come into direct contact with liquids, except

where explicitely specified. Danger of short-circuit!

If they do come into direct contact with a liquid, immediately

disconnect the power supply! Before bringing the system

back into operation, it is essential that all affected components are completely dry and have been inspected by a suitably qualified technician.

WARNING Protect the M3000® automation system, M3000® modules, and the license key from electrostatic discharges!

Electrostatic discharges might damage the device's internal

components or delete the device's internal memory.

2.2.4 Project Planning and Installation

Safety Instructions:

Project Planning and

Installation

WARNING The vent holes of M3000® modules facilitate convection

cooling and must never be covered!

Covered vent holes might result in overheating and fire.

WARNING No work of any kind, such as mounting, removing, wiring, or repairs to the M3000® automation system or

M3000® modules may be performed while the automation system or the modules are in operation!

There is a danger of:

• Uncontrolled movements

• Permanent damage

• Malfunctions

Before performing any work on the M3000® automation system or M3000® modules, it is essential that the system is

stopped and the power supply is disconnected.

Therefore, all power supplies must be switched off, including

those from attached peripherals such as externally supplied

transmitters, programming devices, etc.!

WARNING M3000® modules must be protected from overvoltages

and/or reverse energization from the sensor to the module!

There is a danger of:

• Permanent damage by overheating or fire

• Malfunctions

M3000® modules must have the correct voltage, polarity, and

terminal assignments.

WARNING The internal electronics of M3000® modules and attached sensors must be supplied with power from a permanently connected (unswitched) power supply that

cannot be individually switched off, without switching

off the module's power supply.

If a switched power supply is used, such as when there are

intermediate switching devices (emergency stops, manual

operators, etc.), the following problems might arise, depending on the state of the power supply for the internal electronics of the module and sensors (Ö-table-3 on page 41):

• Reverse energization from sensor to module

• Invalid sensor data

WARNING Sensors that are connected to digital inputs of M3000®

modules with several I/O groups, such as MSC I, QDIO,

or RDIO, must under all conditions be supplied from the

same power supply as the corresponding I/O-group to

which the sensor is connected!

Otherwise, if the power supply for the internal electronics of

the module is switched off, there might be reverse energization from the sensor to the module.

There is a danger of:

• Uncontrolled movements

• Fault or failure of a manual control

• Permanent damage to the module

• Malfunctions

Digital I/Os of MSC II and MSD Motion Controller are protected against reverse energization.

More on these subjects:

Ö-"5-Mechanical Installation" on page 29 or

Ö-"6-Project Planning and Installation" on page 37

To avoid damage to M3000® modules or accessories,

cleaning, maintenance, and repair tasks may be performed only by Moog or Moog's authorized service

agents.

Warranty and liability claims for personal and material damage are excluded when, among other reasons, they are due

to unauthorized repairs or other unauthorized interventions.

Ö-"1.4-Warranty and Liability" on page 3

WARNING No work of any kind, such as mounting, removing, wiring, or repairs to the M3000® automation system or

M3000® modules may be performed while the automation system or the modules are in operation!

There is a danger of:

• Uncontrolled movements

• Permanent damage

• Malfunctions

Before performing any work on the M3000® automation system or M3000® modules, it is essential that the system is

stopped and the power supply is disconnected.

Therefore, all power supplies must be switched off, including

those from attached peripherals such as externally supplied

transmitters, programming devices, etc.!

ARNING The M3000® automation system and M3000® modules

must not come into direct contact with liquids, except

where explicitely specified. Danger of short-circuit!

If they do come into direct contact with a liquid, immediately

disconnect the power supply! Before bringing the system

back into operation, it is essential that all affected components are completely dry and have been inspected by a suitably qualified technician.

WARNING If an M3000® module is to be taken out of operation, the

entire system must always be shut down and disconnected from all power supplies.

Therefore, all power supplies must be switched off, including those from attached peripherals such as externally supplied transmitters, programming devices, etc.!

The M3000® module must be protected against unintentional restarting!

If the M3000® module is connected to other devices and/or

facilities, always consider the full consequences and take appropriate precautions before switching off the module.

Maintain, under all circumstances, the required environmental conditions specified for transportation and storage of the M3000® automation system or M3000® modules.

Ö-"9.1-Environmental Conditions" on page 71

This ensures fault-free, reliable, and safe operation.

2.2.7 Communication Between MSC II and MACS

Safety Instructions:

Communication Between

MSC II and MACS

More on this subject:

Ö-"10.5-Programming and Configuration" on page 84

2.2.8 License Key of the MSC II

Safety Instructions:

License Key of the

MSC II

More on this subject: Ö-"10.6-License Key" on page 85

WARNING The MSC II control module's operational state can be altered with the MACS development environment when the

MSC II control module is connected online with MACS.

This can be done by means of the following actions, for example:

• Stopping or resetting the program

• Setting breakpoints

• Activating the single step mode

• Downloading application programs

• Writing or forcing values

Therefore, the operator must always consider the effects and

take appropriate precautions before altering the operational

state of the MSC II control module with MACS.

The license key of the MSC II control module must be

protected from electrostatic discharges!

Electrical discharges might damage the license key or delete

the contents of the license key's memory.

WARNING The license key may be inserted or removed only when

the MSC II control module is powered down!

Attempting to insert or remove the license key during operation might damage the license key or the MSC II control module permanently.

WARNING The license key must always remain inserted while the

MSC II control module is in operation. Otherwise, the

MSC II control module will not work.

If the license key is removed during operation, the application

program will stop after a few minutes. If the MSC II control

module is connected online to the MACS development environment, a corresponding error message will appear in

MACS.

In addition, the digital output 'Outputs Enabled' will be

switched to the 0 state, thereby disabling all of the MSC II

control module's digital outputs and terminating fieldbus communication and E-bus communication.

Ö-"10.17.2-'Outputs Enabled' Output (LED «OutEN»)" on

page 111

After switching off the MSC II control module and inserting

the license key, the MSC II control module can be brought

back into operation

2.2.9 Run/Stop/Reset

Safety Instructions:

Run/Stop/Reset

More on this subject: Ö-"10.7-Run/Stop/Reset Switch" on page 88

2.2.10 Switching Back on or Resetting the MSC II

Safety Instructions:

Switching Back on or

Resetting the MSC II

More on this subject:

Ö-"10.8.1-Behavior at Switching on and Switching off" on page 89

2.2.11 'Outputs Enabled' Output of the MSC II

Safety Instructions:

'Outputs Enabled' Output

of the MSC II

More on this subject:

Ö-"10.17.2-'Outputs Enabled' Output (LED «OutEN»)" on page 111

WARNING If the most recent status in the online mode (MACS

logged in) was 'Run' before the MSC II control module

was switched off or reset, the boot project will always be

started after the MSC II control module is switched back

on or reset.

This will occur regardless of which application program was

previously running.

In other words, the application program that will be started

automatically after the MSC II control module is switched on

or reset might be different from the application program that

was executing immediately prior.

WARNING If the most recent status in the online mode (MACS

logged in) was 'Run' before the MSC II control module

was switched off or reset, the boot project will always be

started after the MSC II control module is switched back

on or reset.

This will occur regardless of which application program was

previously running.

In other words, the application program that will be started

automatically after the MSC II control module is switched on

or reset might be different from the application program that

was executing immediately prior.

If there is a defect in an output stage, the 'Outputs Enabled' signal will not necessarily shut down all of the

outputs securely

3 Short M3000® System Overview

Short M3000®

System Overview

The M3000® automation system comprises the following hardware and software components:

• MSC II starter kit

Complete package including everything needed to get started with

MSC II

Ö-"3.2-MSC II Starter Kit" on page 15

• M3000® modules

– MSC I (Moog Servo Controller)

Control module for DIN top-hat rail mounting

Ö-"3.3.1-MSC I" on page 16

– MSC II (Moog Servo Controller)

Control module for DIN top-hat rail mounting

Ö-"3.3.2-MSC II" on page 17

– QDIO 16/16

Digital I/O extension module for local extension of the inputs and

outputs of MSC I or MSC II (connection over E-bus)

Ö-"3.3.3.1-QDIO and QAIO" on page 18

– QAIO 2/2

Analog I/O extension module for local extension of the inputs and

outputs of MSC I or MSC II (connection over E-bus)

Ö-"3.3.3.1-QDIO and QAIO" on page 18

– QAIO 16/4

Analog I/O extension module for local extension of the inputs and

outputs of MSC I or MSC II (connection over E-bus)

Ö-"3.3.3.1-QDIO and QAIO" on page 18

– QEBUS-CAN

CAN extension module for MSC II which can be used to make available the LocalCAN bus of an E-bus group for external CAN bus network stations (over a D-sub front panel connector)

Ö-"3.3.3.2-QEBUS-CAN" on page 19

– RDIO

Remote module with digital I/Os and CANopen interface (connection over CAN bus)

Ö-"3.3.4.1-RDIO" on page 20

– RDISP

Display and operating terminal with TIA/EIA 232 and CANopen interface (connection over CAN bus)

Ö-"3.3.4.2-RDISP" on page 20

– DialogController

Displays with TFT technology and touch screen. Programmable

with MACS development environment. Data exchange via Ethernet

with MSC II or MSD Motion Controller.

Ö-"3.3.4.3-DialogController" on page 21

– MSD Motion Controller

Motion control module for MSD Servodrives

Ö-"3.3.5-MSD Motion Controller" on page 22

– MSD Servodrive

Modular Multi-Axis Programmable Motion Control Servodrive

Ö-"3.3.6-MSD Servodrive" on page 23

• License keys

Hardware keys necessary for the operation of the MSC I, MSC II and

MSD Motion Controller.

Ö-"3.4-License Key" on page 24

• MACS (Moog Axis Control Software)

Development environment according to IEC 61131 for solving complex

control tasks

Ö-"3.5-Application Programs" on page 25

• MACS HMI (Moog Axis Control Software Human Machine Interface)

Visualization package which can be run without MACS

Ö-"3.6.1-MACS HMI Visualization Package" on page 26

3.1 M3000® System Architecture

M3000® System

Architecture

The M3000® automation system has the hardware and software structure

necessary for modular and flexible automation solutions with distributed intelligence.

The MSC II control module can use an Ethernet connection (LAN, company Ethernet

network, peer-to-peer connection) to communicate with another controller,

development environment, or visualization package.

Ö-"7.1-Ethernet" on page 47

Ö-"10.5.1-Communication Between MSC II and MACS" on page 84

Ö-"10.5.1.1-Ethernet Communication Interface" on page 84

To create real time capable applications, even in distributed systems and to CAN Bus

give the application a better structure, M3000® can also be divided hierarchically.

Ö-"7.5-CAN Bus and CANopen" on page 55

WideCAN and LocalCAN are two equal, mutually independent CAN bus interfaces. In a typical application they are used as follows:

• WideCAN can be used for networking of individual control groups or re- WideCAN

mote modules. Usually, WideCAN is used for synchronization and data

exchange between the control groups and operating stations of a machine or system.

Ö-"3.3.4-R-Modules (Remote Modules)" on page 19

Ö-"7.7.4-WideCAN Bus Groups" on page 67

In addition, the WideCAN network can integrate other components with

a CAN bus or CANopen interface, such as motor controllers, hydraulic

valves, and radial piston pumps.

• LocalCAN connects the DIN rail modules within a LocalCAN bus group LocalCAN

and, if applicable, the QEBUS-CAN to the connected LocalCAN bus

groups or CAN sensors/actuators.

Ö-"3.3.3.2-QEBUS-CAN" on page 19

Ö-"7.7.3-LocalCAN Bus Groups" on page 66

The M3000® modules mentioned here represent only a part of Moog's

current product range. In addition to other M3000® modules, Moog's

product range includes a large variety of accessories.

Ö-"11-Product Range" on page 114

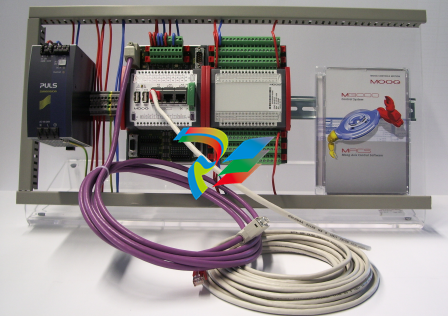

The MSC II starter kit is available in two versions:

• MSC II with Profibus-DP slave

• MSC II with dual EtherCAT master

It includes everything needed to get started:

• MSC II

• Power supply 24 V 10 A

• License key, green

• QDIO 16/16-0,5

• MACS development environment

• Software maintenance contract

• Crossed Ethernet interface cable, 10 m (10.94 yd)

• CAN bus interface cable, 3 m (3.28 yd)

• 6 Plug-in terminal strips with screw terminals, 18 pole

• 2 Plug-in terminal strip with screw terminals, 9 pole

• 4 Plug-in terminal strips with spring power clamp, 10 pole

The included DIN rail modules MSC II and QDIO are mounted (together with

the power supply) on a single mounting plate.

A suitable power cord is the only additional item required to facilitate connection to the power source.

3.3 M3000® Modules

3.3.1 MSC I

MSC I

Figure 2: MSC I Control Module

The MSC I digital control module is a fully programmable multi-axis controller.

The inputs and outputs of the MSC I can be extended locally by attaching

Q-modules. The MSC I and the attached modules then form an E-bus group.

MSC I and Q-modules within E-bus groups communicate over the internal

E-bus.

The MSC I is programmed and configured with the MACS development environment (complies with IEC 61131).

Ö-"3.5-Application Programs" on page 25

The M3000® modules mentioned here represent only a part of Moog's

current product range. In addition to other M3000® modules, Moog's

product range includes a large variety of accessories.

Ö-"11-Product Range" on page 114

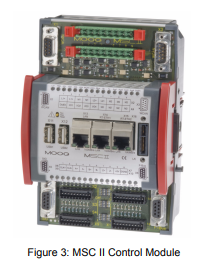

3.3.2 MSC II

The MSC II digital control module is a fully programmable multi-axis controller.

The inputs and outputs of the MSC II can be extended locally by attaching

Q-modules. The MSC II and the attached modules then form an E-bus group.

MSC IIs and Q-modules within E-bus groups communicate over the internal

E-bus.

Ö-"7.7.2-E-Bus Groups" on page 65

The MSC II is programmed and configured with the MACS development environment (complies with IEC 61131).

Ö-"3.5-Application Programs" on page 25

3.3.3 Q-Modules

Q-Modules are I/O extension modules for MSC I and MSC II. Q-Modules

The following Q-modules are available from Moog:

• QDIO 16/16 (digital I/O extension module)

Ö-"3.3.3.1-QDIO and QAIO" on page 18

• QAIO 2/2 (analog I/O extension module)

Ö-"3.3.3.1-QDIO and QAIO" on page 18

• QAIO 16/4 (analog I/O extension module)

Ö-"3.3.3.1-QDIO and QAIO" on page 18

• QEBUS-CAN (CAN extension module)

Ö-"3.3.3.2-QEBUS-CAN" on page 19

Q-modules can be used only as E-bus slaves within E-bus groups.

Ö-"7.7.2-E-Bus Groups" on page 65

When using an RDIO as E-bus master, only QDIOs can be used as E-bus

slaves.

Ö-"7.6.2.1-E-Bus Master and E-Bus Slaves" on page 61

Detailed information about the MSC II:

Ö-"10-MSC II (Moog Servo Controller)" on page 72

Refer to the Q-modules' documentation for more detailed information

3.3.3.1 QDIO and QAIO

QDIO and QAIO I/O extension modules can be used to locally extend the inputs and outputs of an MSC I or MSC II. They have no internal intelligence.

Instead, the MSC I or MSC II actuates them via I/O operation directly over the

internal E-bus.

QDIO 16/16-0,5 is a digital I/O extension module with 16-digital inputs and QDIO 16/16-0,5

16-individually configurable digital I/Os.

QDIO 16/16-0,5 provides positive switching inputs and I/Os.

QDIO 16/16-0,5N provides zero switching inputs and I/Os.

QAIO 2/2 is an analog I/O extension module with 2 analog inputs (each con- QAIO 2/2

figurable as ±10 V, ±10 mA, 4-20 mA) and 2 analog voltage outputs-(±10 V

additionally each configurable as ±10 mA, 4-20 mA, ±50 mA).

QAIO 16/4 is an analog I/O extension module with 16-analog inputs and QAIO 16/4

4-analog voltage outputs-(±10 V).

QAIO 16/4-V provides 16-voltage inputs (±10 V).

QAIO 16/4-A provides 16-current inputs (0–20 mA).

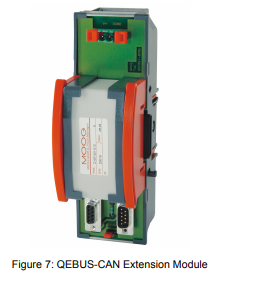

3.3.3.2 QEBUS-CAN

QEBUS-CAN is a CAN extension module which can be used to make the

LocalCAN bus of an E-bus group available for external CAN bus network stations (over a D-sub front panel connector).

3.3.4 R-Modules (Remote Modules)

R-Modules

(Remote Modules)

R-Modules are extension modules with CANopen interface.

The following R-modules are available from Moog:

• RDIO (remote module with digital I/Os and CANopen interface)

Ö-"3.3.4.1-RDIO" on page 20

• RDISP (display and operating terminal)

Ö-"3.3.4.2-RDISP" on page 20

IEC 61131 application programs cannot run on R-modules.

R-modules connect to other network stations over the CAN bus.

Ö-"7.4.1-TIA/EIA 232 Interface Cables" on page 54

Refer to the R-modules' documentation for more detailed information.

3.3.4.1 RDIO

RDIO is a remote module with digital I/Os and CANopen interface. RDIOs

can be parameterized as a CANopen slave according to CiA DS 401.

RDIO 16/16-0,5 provides 16-positive switching digital inputs and 16 positive RDIO 16/16-0,5

switching digital I/Os.

RDIO is a remote module with digital I/Os and CANopen interface. RDIOs

can be parameterized as a CANopen slave according to CiA DS 401.

RDIO 16/16-0,5 provides 16-positive switching digital inputs and 16 positive RDIO 16/16-0,5

switching digital I/Os.

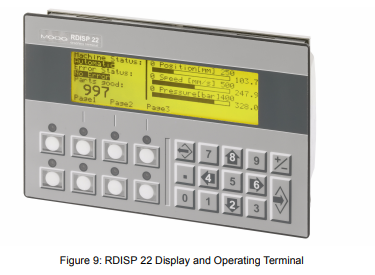

RDISP is a versatile display and operating terminal with TIA/EIA 232 and

CANopen interface as well as a graphical LCD display and function keys

which can be labelled. A slip of paper can be inserted below the keys for labeling purposes.

RDISP 22 provides 22-function keys and a display with max. 8 lines of RDISP 22

40-characters each or random graphics.

Dimensions of RDISP 22:

187 mm × 120 mm × 56 mm (7.36 in × 4.72 in × 2.2 in)

The CPRDISP software (needed to program and configure the RDISP) CPRDISP

is not included with RDISP. CPRDISP is available from Moog as an accessory.

3.3.4.3 DialogController

The DialogController is freely programmable with the Moog Axis Control Software (MACS) development environment. The predefined visualization elements such as buttons, bar graphs, meters, tables and histograms makes it

easy to create visualization screens.

In addition it offers TFT technology for brilliant colors, fanless operation,

Ethernet communication for programming and operation.

It is available in three sizes:

• DialogController 5.7 "

Color TFT, ¼ VGA resolution, 320 x 240 pixels with touch screen

Dimensions: W x D x H: 194 x 172 x 52 mm / 7.6 x 6.8 x 2.0 inch

• DialogController 10.4 "

Color TFT, VGA resolution, 640 x 480 pixels with touch screen

Dimensions: W x D x H: 360 x 260 x 77 mm / 14.2 x 10.2 x 3.0 inch

• Display 12.1 "

Color TFT, SVGA resolution, 800 x 600 pixels with touch screen

Dimensions: W x D x H: 440 x 300 x 77 mm / 17.3 x 11.8 x 3.0 inch

.png)

.png)

.png)