MOOGM-DRIVEINSTALLATION/START-UP GUIDE

M-DRIVE INSTALLATION/START-UP GUIDE

CAUTION

Hazardous Voltages. Can cause severe injury, death or damage to

equipment. The M-Drive should only be installed by a qualified

electrician.

Proper earth grounding of all electronic equipment is required for

successful operation. Connect a low impedance earth ground to

terminal 7 of connector J2.

Separate all logic and signal level wiring (J1, J3 and J4) from all

motor armature and AC power wiring (J2).

Shield all logic and signal wiring (J1, J3 and J4) and terminate to

earth ground at one point only

SCALING

After completing the required wiring of the M-Drive, follow the procedure below to scale the M-Drive for Master

format RPM operation. Complete this procedure before scaling the M-Drive for engineering units.

1. While pressing the ìCLEARî and ì7î keys on the keypad, apply AC power to the M-Drive

(loads factory default parameters).

2. Enter the pulses-per-revolution of the feedback sensor into CP-31. The keypad sequence for a 60 tooth gear

sensor is ìCode Selectî, ì3î, ì1î, ìEnterî, ì6î, ì0î, ìEnterî.

3. Enter the maximum system operating RPM into CP-20, CP-22, CP-34 and CP-37. If the feedback sensor is not

directly connected to the motor shaft, enter the maximum feedback sensor shaft RPM.

4. Press the ìSETSPEEDî key and enter ½ of the RPM entered in Step 3.

5. Press the RUN pushbutton.

6. Verify the motor direction is forward (exchange A1 and A2 if not forward).

7. Press the ìTACHî key. Verify an RPM reading appropriate to the motor setpoint speed.

8. Press the R-Stop pushbutton.

The M-Drive is now properly scaled in RPMs. If engineering unit setpoints and/or displays other than RPMs are

desired, refer to Chapter 5 of the ìM-Drive User Manualî .

TUNING

If the drive system acts unstable or sluggish in response to setpoint or load changes, it may be necessary to tune the

M-Drive. Follow the procedure below to improve system performance:

1. Set CP-66 (Integral) and CP-67 (Derivative) to zero.

2. Reduce CP-65 (Gain) until the system goes unstable (erratic). Stability can be tested by moving between two

wide spread setpoint values. When instability is reached, increase the CP-65 number slightly until the system

stabilizes (larger values reduce the system gain).

3. Using only Gain, the system setpoint value may never be reached due to system losses. Reduce CP-66 (Integral)

until the system becomes unstable, then increase the Integral number slightly until the system stabilizes and the

desired setpoint value is reached.

4. Derivative (CP-67) is only required if the system is too sluggish after setting the Gain and Integral terms. The

Derivative value, like Gain, should be reduced to the point of instability, then increased slightly until the system

regains stability

FOLLOWER OPERATION

Complete the ìScalingî and ìTuningî procedures for Master mode (Page 2) before proceeding with Follower opera

tion. To enable Follower operation, follow the procedure below:

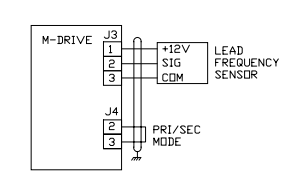

1. Wiring additions:

2. Enter the pulses-per-revolution of the lead (External Reference) sensor into CP-30 (PPR Ext Ref).

3. Enter the maximum system operating RPM of the lead motor (or sensor shaft if not directly connected to the

motor) into CP-36 (RPM Ref Secondary Max).

4. The M-Drive is now scaled for ratio follower operation. Setpoint and display values are in ratio of follower/lead.

If engineering unit setpoints and/or displays other than ratio are desired, refer to Chapter 5 of the ìM-Drive User

Manualî.

5. Enter the desired operating ratio into CP-3 (Follower Setpoint).

TROUBLE-SHOOTING

Master Mode: Motor Will Not Run

Step 1: Check MV-53 (Control State).

a) Should be ì32î (Run).

b) If not ì32î, check the Run, R-Stop and F-Stop wiring.

Step 2: Check MV-45 (Scaled Reference).

a) Should not be zero.

b) Press ìSETSPEEDî and enter a midrange value setpoint.

c) Enter a value greater than max motor speed (CP-34) into CP11 (Maximum Limit).

d) Enter a ì1î into CP-61 (Scaling Mode Pri) and CP-63 (Display Mode Pri).

Step 3: Check MV-46 (Ramped Reference).

a) Should not be zero.

b) If MV-46 is zero, check MV-54 for a value of 247 or 255.

c) If MV-54 is not 247 or 255, check wiring according to Chapter 3 of the ìM-Drive User Manualî.

Step 4: Check MV-47 (Output).

a) Should not be ì0î or ì100î.

b) If ì0î, then return to step 1 of ìScalingî.

c) If ì100î, check wiring to motor.

Step 5: If armature contactor is used, make sure it is energized.

Master Mode: Motor At Full Speed

Step 1: Press ìSETSPEEDî and enter midrange setpoint.

Step 2: Check MV-43 (Feedback Frequency).

a) Should not be zero.

b) Check that signal is present at feedback input (J3 Pins 5 and 6).

c) Check the feedback configuration jumpers per Chapter 2 of the ìM-Drive User Manualî.

Step 3: Stop the M-Drive.

Step 4: If motor does not stop, check MV-47 (Output).

a) Should be zero.

b) Check MV-53: Should be ì64î or ì128î.

c) If not, check R-Stop and F-Stop wiring.

Step 5: If motor is still running, suspect false-fired or bad SCRís.

Follower Mode: Motor Will Not Run

Step 1: Check unit out in Master Mode first.

Step 2: Check MV-54 (Control Mode)

a) Should be less than 128.

b) If not, check wiring to verify that Follower mode has been selected.

.png)

.png)

.png)