HIMA HIMax® Safety System: Technical Summary

HIMA HIMax® Safety System: Technical Summary

Introduction

This document provides a technical overview of the HIMA HIMax® safety system, a platform engineered for nonstop safety and maximum productivity in critical applications. HIMax is designed to prevent unscheduled shutdowns while ensuring the highest level of safety, making it suitable for the world's most demanding process industries. All information is based on the official HIMax product brochure.

Core Philosophy: "Safety. Nonstop."

The fundamental principle of HIMax is to deliver uncompromising safety (up to SIL 3) without interrupting plant operations. This is achieved through a unique combination of fault-tolerant architecture, high performance, and the ability to perform maintenance, modifications, and expansions online without a system shutdown.

XMR Architecture: Scalable Redundancy

At the core of HIMax is the revolutionary XMR architecture, which combines the benefits of various redundancy concepts. The "X" can represent values from 1 to 4, allowing the system to be scaled from a single (1oo1), dual (1oo2), triple (TMR, 1oo3), to a quad (1oo4) configuration. This flexibility allows users to tailor the system's fault tolerance and availability to meet specific application requirements, protecting against both random hardware failures and common-cause failures through physical separation of redundant components.

Key Features for Nonstop Operation

HIMax is engineered from the ground up to maximize uptime and productivity:

Online Modifications: The system allows for hardware and software changes, including operating system updates, to be performed while the system is running, without impacting the process.

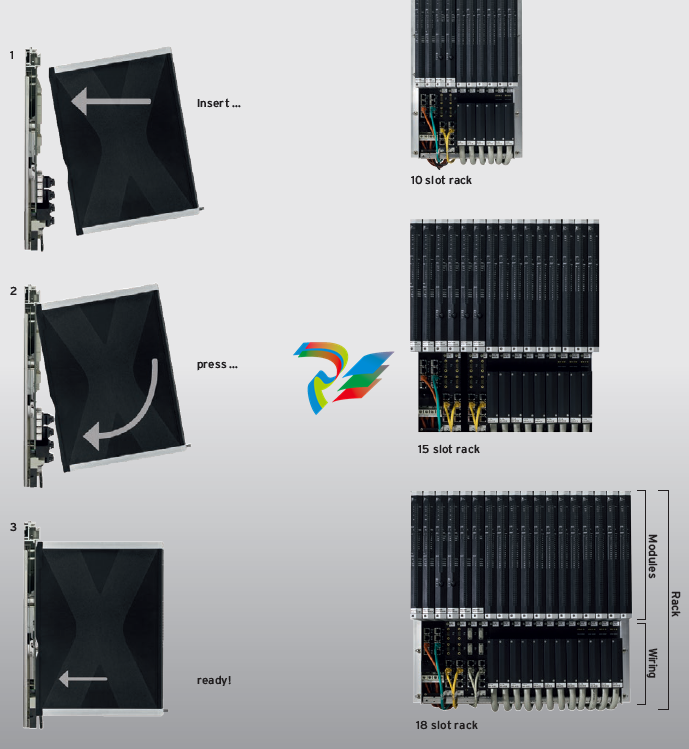

"Self-Education" of Modules: When a faulty module is replaced, the new module is automatically configured and loaded with the correct parameters and user program from the operational modules. This simplifies maintenance and reduces the risk of human error.

Proof Testing without Shutdown: In compliance with IEC 61508 and IEC 61511, required proof tests can be conducted without taking the safety system offline.

Multitasking: The system can simultaneously process up to 32 independent user programs, each with its own defined cycle time. This allows for the consolidation of time-critical and non-time-critical applications (e.g., ESD and Turbine Control) within a single controller.

Performance and Scalability

HIMax is a high-performance platform capable of handling large and complex applications.

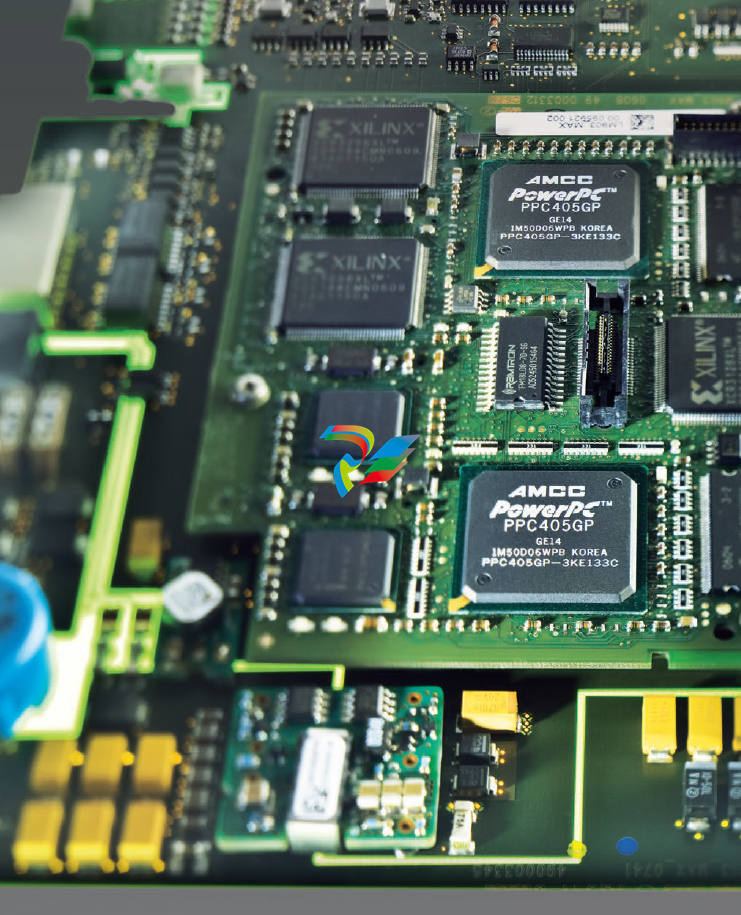

Processing Power: Delivers fast cycle times (e.g., 50 ms for a system with 1,000 I/Os) and can handle complex calculations with minimal impact on performance.

I/O Capacity: Can support up to 2,048 I/Os per cabinet and a total of 12,800 I/Os per system.

Distributed Architecture: Offers extensive networking capabilities:

Remote Racks: Up to 16 remote racks can be distributed over long distances (up to 20 km via fiber optics) using the redundant system bus.

safeethernet: Allows for the networking of up to 255 HIMax systems over any standard Ethernet infrastructure with SIL 3 integrity and 1 GBit/s speed.

SILworX: Integrated Engineering Environment

HIMax is configured, programmed, and diagnosed using SILworX, a unified and intuitive software tool.

IEC 61131-3 Compliant: Supports standard programming languages like Function Block Diagram (FBD), Sequential Function Chart (SFC), and Structured Text (ST). It also allows for the integration of custom C code.

User-Friendly: Features drag-and-drop programming, automatic project saving, comprehensive cross-references, and powerful validation tools including offline simulation and online testing.

Lifecycle Management: Integrated version comparison and maintenance logs provide clear traceability of all changes made to the system.

Applications and Integration

HIMax is designed as a single, flexible platform for a wide range of safety-critical applications, including:

Emergency Shutdown Systems (ESD)

Fire & Gas (F&G) Systems

Burner Management Systems (BMS)

High-Integrity Pressure Protection Systems (HIPPS)

Turbomachinery Control (TMC)

The system integrates seamlessly with all leading Distributed Control Systems (DCS) using standard protocols like OPC, Modbus TCP, and PROFIBUS DP.

Conclusion

The HIMA HIMax system represents the pinnacle of safety automation technology, offering unparalleled performance, flexibility, and availability. Its unique XMR architecture and "nonstop" operational philosophy allow industrial facilities to maximize both safety and productivity, making it the ideal choice for the most critical and demanding applications across the globe.

.png)

.png)

.png)