WATLOWCAS200 User’s GuideSystem Overview

regulations require that you use independent external

safety devices to prevent potentially dangerous or unsafe

conditions. Assume that the CAS200 can fail or that other

unexpected conditions can occur.

Install high or low temperature protection in systems

where an overtemperature or undertemperature fault

condition could present a fire hazard or other hazard.

Failure to install temperature control protection where a

potential hazard exists could result in damage to

equipment and property, and injury to personnel.

For additional process safety, program a computer or other

host device to automatically reload your desired operating

parameters after a power failure. However, this safety

feature does not eliminate the need for other external,

independent safety devices in dangerous conditions.

The CAS200 should never be used as a safety

shutdown device. It should only be used with

other approved independent safety shutdown

devices.

Contact Watlow Anafaze immediately if you have any

questions about system safety or system operation.

This chapter describes how to install the CAS200 series

scanner and its peripherals. Installation of the scanner

involves the following procedures:

• Determining the best location for the scanner

• Mounting the scanner and TB50

• Power Connection

• Input Wiring

• Communications Wiring (EIA/TIA-232 or EIA/TIA485)

• Output Wiring

Typical Installation

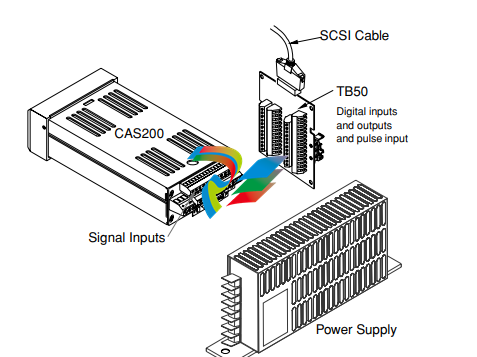

The illustrations below show typical installations of the

scanner with the TB50 terminal block. Observe the

illustration below to determine potential space

requirements.

We recommend that you read this entire chapter first

before beginning the installation procedure. This will help

you to carefully plan and assess the installation.

Figure 2.1 System Components

Safety

∫

WARNING! Ensure that power has been shut off to your entire

process before you begin installation of the

scanner

Watlow Anafaze has made every effort to ensure the

reliability and safety of this product. In addition, we have

provided recommendations that will allow you to safely

install and maintain this scanner.

∫

WARNING! In any application, failures can occur. These

failures can result in full control output (100%

power), or the occurrence of other output failures

which can cause damage to the scanner, or to the

equipment or process connected to the scanner.

Therefore, always follow good engineering

practices, electrical codes, and insurance

regulations when installing and operating this

equipment.

External Safety Devices

External safety devices should be used to prevent

potentially dangerous and unsafe conditions upon

equipment failure. Always assume that this device can fail

with outputs full-On, or full-Off, by the occurrence of an

unexpected external condition.

∫

WARNING! Always install high or low temperature protection

in installations where an overtemperature or

undertemperature fault will present a potential

hazard. Failure to install external protection

devices where hazards exist can result in damage

to equipment, property, or human life.

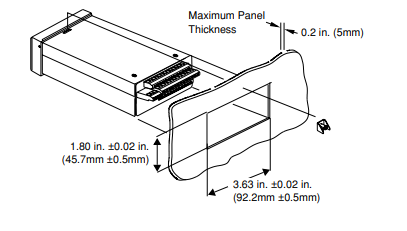

Mounting

We recommend you mount the scanner in a panel not more

than 0.2 inches thick.

∫

WARNING! To reduce the risk of fire or electric shock, install

the CAS200 in a controlled environment,

relatively free of contaminants.

Location

Install the scanner in a location free from excessive (>50°C)

heat, dust, and unauthorized handling.

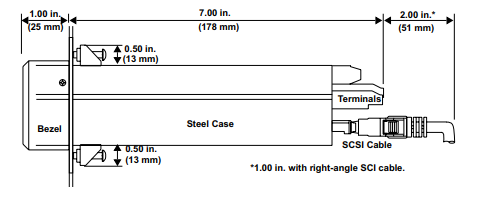

Ensure there is enough clearance for mounting brackets,

terminal blocks, and cable and wire connections; the

scanner extends 7.0 in. behind the panel face and the screw

brackets extend 0.5 in. above and below it. Allow an

additional 1 to 3 inches for the SCSI cable.

Figure 2.2 Clearance Recommendations

Other Tools:

You will also need these tools:

• Phillips head screwdriver

• Flathead screwdriver for wiring

• Multimeter

Mounting the Scanner

Mount the scanner before you mount the TB50 or do any

wiring. The scanner's placement affects placement and

wiring considerations for the other components of your

system.

You receive one of two types of mounting brackets with

your scanner, the mini-bracket or the collar bracket. Refer

to the corresponding sections below for instructions.

Steps Using the Mini-Bracket

1. Cut a hole in the panel to the dimensions shown in the

illustration below. To do this, use a punch, nibbler, or

jigsaw, and file the edges of the hole.

2. Insert the scanner into the hole through the front of

the panel.

3. Screw the top and bottom clips in place: insert the

clip’s lip into the cutout in the scanner’s metal housing

just behind the front panel. Tighten the screws.

4. If you expect much panel vibration, use a rear support

for the scanner and its interconnecting cables.

Figure 2.3 Mounting with the Mini-Bracket

Steps Using the Collar Bracket

Installing and mounting requires access to the back of the

.png)

.png)

.png)