GEFanuc Automation Programmable Control Products

(IC670ALG240), the Thermocouple Input module (IC670ALG630), and the RTD Input module

(IC670ALG620).

LEDs

I/O Module LEDs are easily visible through the transparent central portion of the label. All

modules have an LED that indicates the presence of module power. Discrete modules also have

individual circuit LEDs that show the on/off status of each input or output circuit.

Front Label

The module's front label, shown above, has space for writing circuit identifications.

Module Keying

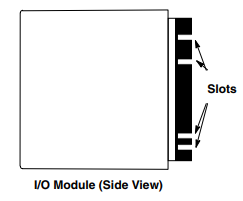

Each type of I/O module is slotted to allow keying. Small key clips (provided) can be inserted into

corresponding slots in the I/O base to assure that the module installed in that location will not cause

damage or unexpected machine operation. Actual keying slots are the same for some types of

modules.

For More Information About I/O Modules, See:

• Chapter 2, Installation.

• The I/O module datasheets in this manual.

• Configuration instructions in the Bus Interface Unit User's Manual.

Environmental Specifications

Vibration Modules perform well where vibration is a factor. Designs are shock and

vibration tested to meet the following specifications when installed on a panelmounted DIN rail using the clamp supplied, and with the panel-mounting feet

secured:

IEC68-2-6: 10 to 57 Hz 0.012 in displacement (peak to peak)

57 to 500 Hz at 2 g (unless otherwise specified)

IEC68-2-27: Shock: 15G, 11 milliseconds, half sine wave

Noise Modules are resistant to noise levels found in most industrial applications

when installed according to accepted practices, including proper separation of

wiring by voltage and power levels, on a conductive (unpainted) DIN rail. The

DIN rail is an integral part of the grounding system.

Modules are tested to the specifications listed in the Conformance to Standards

document (GFK-1079).

Temperature Modules operate reliably in ambient air temperatures from 0°C (32°F) up to

55°C (131°F).

Storage temperatures are -40°C (-40°F) to +85°C (185°F).

Humidity 5% to 95%, non-condensing

I/O Terminal Blocks

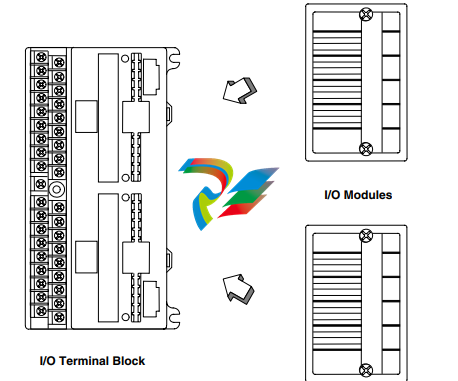

I/O Terminal Blocks are generic wiring bases for Field Control I/O modules. They provide I/O

module mounting, backplane communications, and terminals for user connections.

Two I/O modules can be installed on an I/O Terminal Block. Modules screw onto the terminal

block for vibration resistance.

I/O modules can be removed from the I/O Terminal Block without disturbing field wiring

O Terminal Block General Description

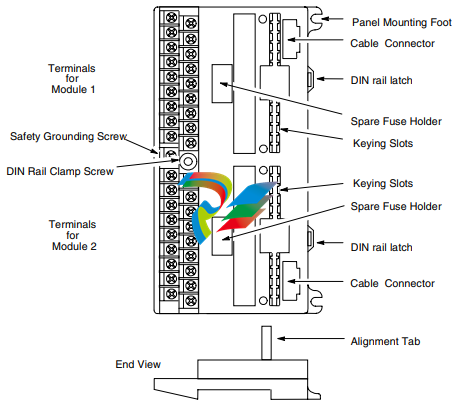

The following illustration shows the basic parts of an I/O Terminal Block.

The I/O Terminal Block has two separate sets of module terminals. Each set corresponds to a

“slot” in a conventional rack-type PLC. Terminal wiring assignments depend on the I/O module

type installed in that location.

The grounding screw is used to attach a ground wire to the terminal block.

The cable connectors provide easy attachment of the cable that carries communications signals

between terminal blocks and the Bus Interface Unit.

The spare fuse holders can be used to store extra fuses (if needed) for the I/O modules.

The DIN rail latches clip the I/O Terminal Block to a DIN rail. Pulling these latches outward

releases the DIN rail.

The keying slots permit protective keying. Inserting the key clips provided into these slots assures

that the module installed in that location will not cause damage or unexpected machine operation.

I/O Terminal Blocks IC670CHS101, 102, and 103 have projecting alignment tabs designed to

facilitate Hot Insertion/Removal of modules. I/O Terminal Blocks IC670CHS001, 002, and 003,

which lack alignment tabs, do not support Hot Insertion/Removal of modules.

nstallation

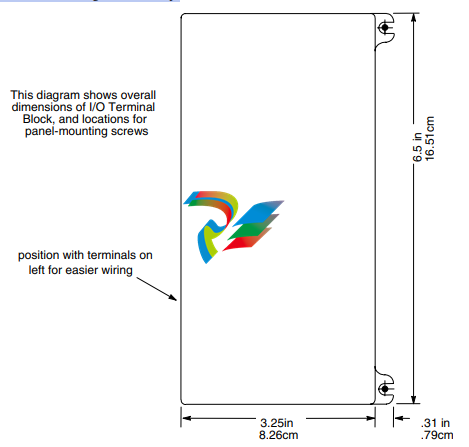

The I/O Terminal Block can be installed in any orientation; the preferred vertical orientation for

easier wiring installation is with the wiring terminals on the left and the panel-mounting feet on the

right as shown below. The preferred horizontal orientation is with the wiring terminals at the

bottom and the mounting feet at the top.

Field Control terminal blocks must be installed on a 35mm x 7.5mm DIN rail, which becomes an

integral part of the grounding system. The DIN rail finish must be electrically conductive. The

DIN rail must not be painted.

The DIN rail should be mounted on a panel for added vibration resistance.

The overall depth of Field Control modules when mounted on terminal blocks and installed on a

35mm x 7.5mm DIN rail is 4.0 inches (10.16 cm).

.png)

.png)

.png)