parkerQUICK START MANUAL VM600 machinery protection system (MPS)

dangerous and may damage the equipment or result in injury.

Read the following recommendations carefully before handling electronic

circuits, printed circuit boards or modules containing electronic

components

INSTALLATION

This chapter provides a brief overview on the installation of VM600 machinery protection

system (MPS) hardware. Information is provided on unpacking, installing a rack, connecting

power, connecting cards and software configuration.

NOTE: For further information on installing a VM600 machinery protection system (MPS),

refer to the VM600 machinery protection system (MPS) hardware manual.

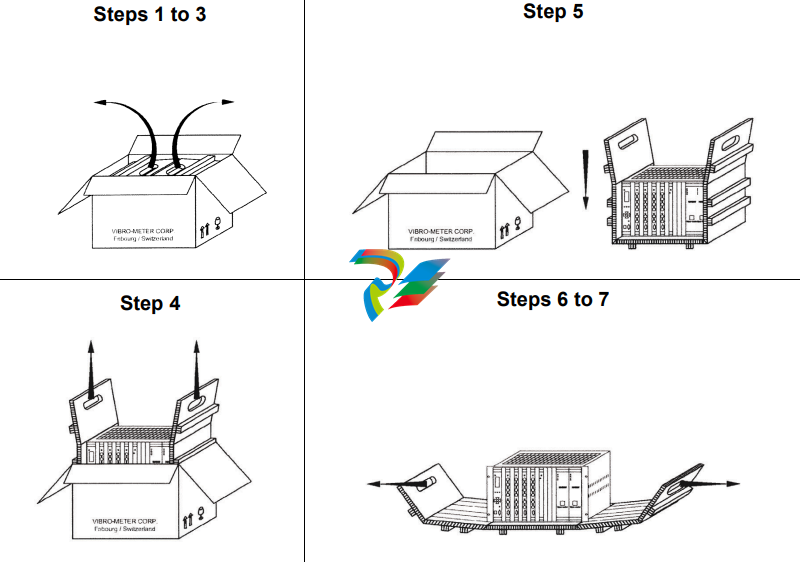

1.1 Unpacking and inspecting

The procedure for unpacking VM600 MPS hardware is shown in Figure 1-1 and described

below:

Figure 1-1: Procedure for unpacking and inspecting VM600 MPS hardware

Step 1: Place the outer box on a flat surface with the arrows on the side of the box

pointing upwards.

Step 2: Open the outer box along the tape using a pair of scissors.

Step 3: Pull the handles of the inner box outwards to a vertical position.

Step 4: Gently lift the inner box vertically out of the outer box using the handles of the

inner box.

Step 5: Place the inner box on a flat surface.

Step 6: Open the inner box using the handles.

Step 7: Inspect the VM600 MPS hardware to ensure that no damage has occurred

during delivery

If damage has occurred to VM600 MPS hardware during delivery, please contact

your nearest Meggitt representative.

1.2 System overview

The VM600 machinery protection system (MPS) is a digital machinery protection system

designed for use in industrial applications. It is intended primarily for vibration monitoring to

assure the protection of rotating machinery as used in, for example, the power generation,

petro-chemical and petroleum industries as well as in marine related applications.

The VM600 series of machinery protection and condition monitoring systems from Meggitt’s

Vibro-Meter® product line are based around a 19" rack containing various types of cards,

depending on the application.

There are basically two types of system:

• VM600 machinery protection system (MPS – 1U or 6U rack).

• VM600 condition monitoring system (CMS – 1U or 6U rack).

It is also possible to integrate MPS and CMS hardware into the same VM600 rack (ABE04x).

NOTE: This manual describes machinery protection system (MPS) hardware only.

Further information on condition monitoring system hardware can be found in the

VM600 condition monitoring system (CMS) hardware manual.

In its most basic configuration, a VM600 machinery protection system (MPS) consists of the

following hardware:

1- VM600 rack: 19" system rack x 6U (ABE04x) or 19" slimline rack x 1U (ABE056)

NOTE: ABE04x refers to both the ABE040 and ABE042, which are identical apart from the

position of the rack mounting brackets.

2- RPS6U rack power supply (ABE04x only)

When an AC-input version of the RPS6U is installed in a VM600 rack, the optional ASPS

auxiliary sensor power supply can be used to replace external power supplies such as

the APF19x 24 VDC power supplies.

3- MPC4 machinery protection card

4- IOC4T input/output card for the MPC4

5- AMC8 analog monitoring card

6- IOC8T input/output card for the AMC8.

The MPC4 and IOC4T cards form an inseparable card pair and one cannot be used without

the other. These cards are used primarily to monitor vibration for the purposes of machinery

protection.

Similarly, the AMC8 and IOC8T cards form an inseparable card pair and one cannot be used

without the other. These cards are used primarily to monitor quasi-static parameters such as

temperature, fluid level or flow rate for the purposes of machinery protection.

In general, a VM600 rack used for machinery protection can contain:

• Only MPC4 / IOC4T card pairs

• Only AMC8 / IOC8T card pairs

• A combination of MPC4 / IOC4T and AMC8 / IOC8T card pairs.

Depending on the application, the following type of cards can also be installed in the VM600

rack (ABE04x or ABE056):

7- RLC16 relay card (16 relays) and IRC4 intelligent relay card (eight relays combined as

either 4 DPDT or 8 SPDT).

All the above items can be used to make a stand-alone MPS system, that is, one that is not

connected to a network.

A networked version of the MPS will in addition contain the following hardware in the VM600

rack (ABE04x):

8- CPUM modular CPU card

9- IOCN input/output card for the CPUM.

Depending on the application (and irrespective of whether the rack is used in a stand-alone

or a networked configuration), one or more of the following power supplies can be used

outside a VM600 rack (ABE04x):

• APF19x 24 VDC power supplies

• Any equivalent low-noise power supply provided by the customer.

These devices must be used for GSI1xx galvanic separation units, GSV safety barriers and

transducer and signal conditioner front-ends having a current requirement greater than

25 mA. They will often be mounted in the cubicle in which the rack is installed.

NOTE: Auxiliary sensor power supplies (ASPSs) installed in a VM600 rack (ABE04x)

perform the same function as external power supplies such as the APF19x 24 VDC

power supplies. That is, they are used to power external hardware such as GSI

galvanic separation units or signal conditioners that require more power than can

.png)

.png)

.png)