METRIXHIGH TEMPERATURE VELOCITY TRANSDUCER

E/E/PE safety-related systems and other risk reduction measures

safe state

state of the EUC when safety is achieved

The Metrix 5485C is a moving-coil velocity transducer, specifically designed for continuous use

in elevated temperatures. A permanent magnet moving back and forth within a coil winding

induces and electromagnetic field in the windings. This electromagnetic field is proportional to

the velocity of oscillation of the magnet: the magnet shall be mounted on the vibration object

to measure its velocity.

A zero-friction coil suspension provides accurate, repeatable vibration measurements over a

wide range of amplitude and frequency and is built to withstand the high-g environments and

cross-axis vibrations typical of gas turbines. The coil bobbin is suspended by two non-twisting, circular spider springs that

provide a clean frequency response.

Purely viscous electromagnetic damping is employed and eliminates friction-prone air damping. This allows improved

detection of small vibration amplitudes at low frequencies.

The sensor is available in two configurations: with integral armored cable or removable armored cable via a 2-pin MIL-style

threaded connector. The case is constructed of stainless steel and its robust internals are hermetically sealed to ensure

durability in the most hostile environments. The product is approved for use in Zone 2 / Div 2 hazardous areas without use

of intrinsic safety barriers. It is also approved for use in Zone 0/1 and Div. 1 areas with use of an appropriate intrinsic safety

barrier.

The Metrix 5485C Velocity Sensor shall be used in application where there is a continuous vibration of the unit to be

supervised and where the target is the vibration detection over the assigned threshold.

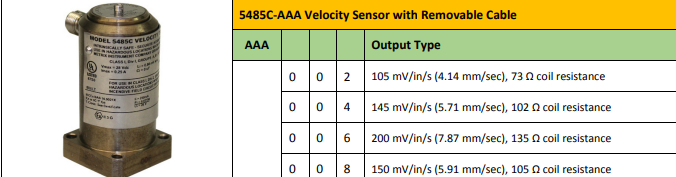

PRODUCTS FAMILY PRODUCTS FAMILYIDENTIFICATION IDENTIFICATION IDENTIFICATION

This Safety Manual is valid for each product listed in this paragraph. In the following table are listed the family models for

the sensor 5485C with Removable Cable. Each sensor is differentiated one from the other by the internal coil resistance: the

latter allows a differential measure sensitivity.

SAFETY PARAMETERS SAFETY PARAMETERS

Specific activities necessary to investigate and reach a judgment on the adequacy of the functional safety achieved by the

E/E/PE safety-related system or compliant items (elements/subsystems) has been conducted by an independent assessor.

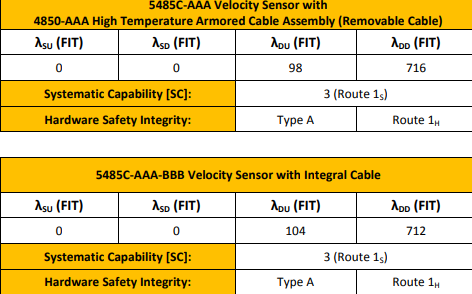

The following failure rates data shall be used to the PFDAVG estimation, taking into consideration all parameters such as

redundancy, architectural constraints, diagnostic capability, also introduced by the whole system, including the

considerations about the proof test and its effectiveness, mean time of restoration, up to the maintenance capability and its

minimum characteristics.

NOTICE

The design of each Safety Instrumented Function shall meet the requirements listed in the reference

standards that shall be selected by taking into account the specific application.

The estimated safety integrity, for each safety function, due to random hardware failures (including soft-errors) and random

failures of data communication processes. The following table shows the failure rates of the device listed in para. 4.1.

NOTICE

The failures rates are distributed considering the ability of the SIS logic solver to detect short circuit and

open circuit, as described in para. 7.

REQUIREMENTS FOR IMPLEMENTATION INTO A SIS REQUIREMENTS FOR IMPLEMENTATION INTO A SIS

The SIS logic solver shall be able to detect the sensor fault through its signal. The most critical failure modes, open circuit and

short, give as a result an output signal equal to zero.

The logic solver used to acquire the 5485C output signal shall have a high internal impedance (not less than 100kΩ).

In order to maintain the safety capability of the sensor, the logic solver shall activate a proper feedback when a zero-voltage

signal is detected. This proper feedback shall be used as fault condition of the sensor. The fault condition shall be properly

managed as per each specific safety function.

NOTICE

The sensor isn’t designed to impulsive vibration. It shall be used in application having a natural vibration

frequency in the range of the sensor in order to allow a proper diagnostic of the correct functionality of the

sensor.

NOTICE

The natural vibration of the equipment under control shall not exceed the transducer maximum

displacement of 1,8mm (70 mils).

After the first installation, and after any replacing or proof test, the right functionality of the sensor through verifying of coilto-case insulation. The electrical test shall be used to discover possible wire damage able to increase the resistance of the

connecting cable.

PROOF TEST PROOF TEST

The proof test is not necessary, since for the entire lifetime, the correct functioning according to the specifications indicated

.png)

.png)

.png)