GEGenerator Protection System Generator Protection, Control and Asset Management

in a peak load control system, consider the accuracy rating and method of

measurement employed, and the source VTs and CTs, in comparison with the

electrical utility revenue metering system.

• In bulk oil circuit breakers, the interrupting time for currents is less than 25% of the

interrupting rating and can be significantly longer than the normal interrupting time.

• For future reference, make a printout of the conversion report immediately after the

conversion in case conversion reports are removed or settings modified from the 8

Series Setup Software.

Mechanical Installation

This section describes the mechanical installation of the 889 system, including dimensions

for mounting and information on module withdrawal and insertion.

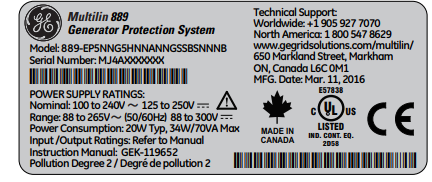

Product Identification

The product identification label is located on the side panel of the 889. This label indicates

the product model, serial number, and date of manufacture.

Figure 2-1: Product Label

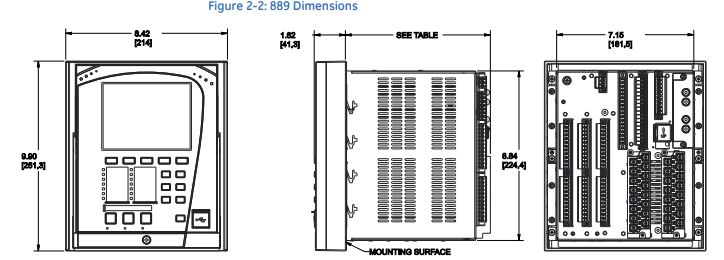

Dimensions

The dimensions (in inches [millimeters]) of the 889 are shown below. Additional dimensions

for mounting, and panel cutouts, are shown in the following sections.

Mounting

The 889 unit can be mounted two ways: standard panel mount or optional tab mounting, if

required.

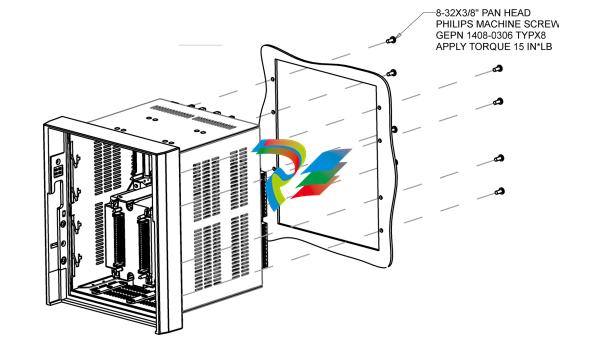

• Standard panel mounting:

From the front of the panel, slide the empty case into the cutout. From the rear of the

panel, screw the case into the panel at the 8 screw positions (see figures in Standard

panel mount section).

• Optional tab mounting:

The “V” tabs are located on the sides of the case and appear as shown in the following

figure. Use needle nose pliers to bend the retaining "V" tabs outward to about 90°. Use

caution and do not bend and distort the wall of the enclosure adjacent to the tabs. The

relay can now be inserted and can be panel wired.

Figure 2-3: “V” Tabs Located on Case Side

Standard Panel Mount The standard panel mount and cutout dimensions are illustrated below. CAUTION: To avoid the potential for personal injury due to fire hazards, ensure the unit is mounted in a safe location and/or within an appropriate enclosure. Figure 2-4: Standard panel mount

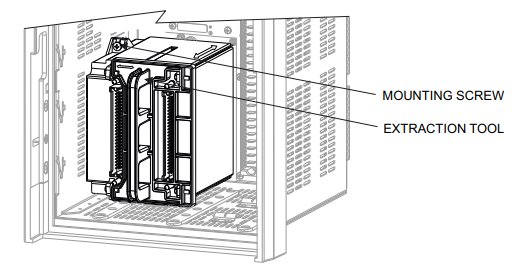

Removable Magnetic Module

IMPORTANT: Prior to the removal of the CT/VT magnetic module, all preparation steps below shall

be adhered to in order to prevent injury.

All current and voltage sources connected to the 8 Series relay must be identified

before starting the removal process.

Removal of the magnetic module from a relay installed in a power system shall only be

performed by suitably-qualified personnel.

Appropriate PPE is required based on the arc flash calculations.

CAUTION: LOTO (Lockout Tag Out) of the system is required prior to module removal/

replacement.

Follow the procedures outlined below to remove or replace the CT/VT magnetic module.

PREPARATION

1. Shut down and de-energize all systems connected to the 8 Series relay

2. Review all points in the section Cautions and Warnings.

IMPORTANT: An 8 Series relay, with the magnetic module removed, does NOT have an internal

automatic CT shorting mechanism.

CAUTION: Hazardous voltages can exist when opening the secondary circuits of live current

transformers. Make sure that in-field current transformer secondary circuits are

shorted out before making or removing any connection to the current transformer (CT)

input terminals of the device (i.e disconnection/connection of 8 Series CT Input

terminals or the internal CT/VT magnetic module).

.png)

.png)

.png)