EMERSONA6110 Shaft Relative Vibration Monitor for AMS 6500 Machinery Health Monitor

The Shaft Relative Vibration Monitor is designed for extremely high reliability for the

plant’s most critical rotating machinery. This 1-slot monitor is used together with

other AMS 6500 monitors to build a complete API 670 machinery protection monitor.

Applications include steam, gas, compressors and hydro turbo machinery.

The main functionality of the Shaft Relative Vibration monitoring module is to

accurately monitor shaft relative vibration and reliably protect machinery by comparing

vibration parameters against alarm setpoints, driving alarms and relays.

Shaft relative vibration monitoring consists of a displacement sensor either mounted

through the bearing case, or mounted internally on the bearing housing, with the

rotating shaft being the target.

The displacement sensor is a non-contact sensor measuring shaft position and

movement. Since the displacement sensor is mounted to the bearing, the monitored

parameter is said to be shaft relative vibration, that is, shaft vibration relative to the

bearing case.

Shaft relative vibration is an important measurement on all sleeve bearing machines

for predictive and protection monitoring. Shaft relative vibration should be selected

when the machine case is massive as compared with the rotor, and the bearing case

is not expected to vibrate between zero and production-state machine speeds. Shaft

absolute is sometimes selected when the bearing case and rotor mass are more closely

equal, where it is more likely that the bearing case will vibrate and impact shaft

relative readings.

The AMS 6500 is an integral part of PlantWeb® and AMS software. PlantWeb provides

operationsintegrated machinery health combined with the Ovation® and DeltaV™

process control system. AMS software provides maintenance personnel advanced

predictive and performance diagnostic tools to confidently and accurately determine

machine malfunctions early

Two-channel, 3U size, 1-slot plugin module decreases cabinet space

requirements in half from traditional

four-channel 6U size cards

API 670 compliant,

hot-swappable module

Remote selectable limit multiply

and trip bypass

Front and rear buffered and

proportional outputs,

0/4-20 mA output, 0-10 V output

Self-checking facilities include

monitoring hardware, power input,

hardware temperature, sensor,

and cable

Use with displacement sensors PR6422,

PR6423, PR6424, PR6425, and driver

CON 011/91, 021/91,041/91

Analysis parameters ½x, 1 to 10x and phase angle of same

Available via ModBus TCP/IP output

Rear Outputs Available

Current mode outputs 0/4-20 mA output for each channel proportional to

main value

- For example, both ouputs are identical combined

for Smax (combined mode)

- For example, both ouputs are independent

for Y and X (independent mode)

Open/short circuit proof

Permissible load <500 Ω

Accuracy ±1% of full scale

Settling time configurable, 0 to 10 seconds

Voltage mode outputs 0-10 VDC output proportional to main value for each

channel

- For example, both ouputs are identical combined

for Smax (combined mode)

- For example, both ouputs are independent

for Y and X (independent mode)

Open/short circuit proof

Permissible load >10 kΩ

Rear buffered outputs Raw buffered output signal, AC and DC

Open/short circuit proof

Frequency range 0.1-16 kHz (-3 dB) 0-16 kHz -3 dB ±20%

Permissible load >10 kΩ

DC voltage outputs 0-10 VDC output proportional to the

shaft position (gap)

Open/short circuit proof

Accuracy ±1% of range

Permissible load >10 kΩ

Alarm Setpoints Alarm Time Delays

Alert Selectable normally open, normally closed

0-5 second delay per channel

0-36 second delay with A6740 relay card

Selectable to be blocked on channel not OK

Adjustable range 5 to 100% of full scale value

Resolution 1% of full scale value

Alarm hysteresis on decreasing signal value,

0 to 20% of full scale value

Danger Selectable normally open, normally closed

0-5 second delay per channel

0-36 second delay with A6740 relay card

Selectable to be blocked on channel not OK

Adjustable range 5 to 100% of full scale value

Resolution 1% of full scale value

Alarm hysteresis on decreasing signal value,

0 to 20% of full scale value

OK Self checking (normally closed):

- Power supply, sensor, cable, module checking,

overload, internal temperature, system watchdog

Green LED:

- Off when not OK

- During delay time, LED flashes

- Reason for not OK can be read from

communication bus

Limit multiply Remote, relay input, 1.00-4.99 factor

Trip bypass Remote, relay input

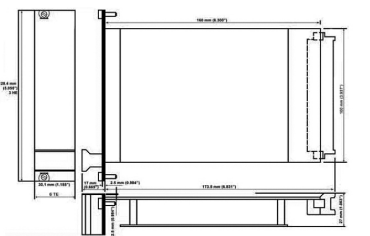

A6110 Dimensions:

PCB/EURO card format according to

DIN 41494, 100 x 160mm (3.937 x 6.300in)

Width: 30.0mm (1.181in) (6 TE)

Height: 128.4mm (5.055in) (3 HE)

Length: 160.0mm (6.300in)

Net Weight: app 320g (0.705lbs)

Gross Weight: app 450g (0.992lbs)

includes standard packing

Packing Volume: app 2.5dm3

(0.08ft3

)

Space requirements: 1 slot

14 modules fit into each 19” rack

Ordering Information

Model Number Product Description

A6110 Dual-channel Shaft Relative

Vibration Monitor

.png)

.png)

.png)