Central unit PM 640 and PM 644: (supports SC 610)

Performance, in this thesis, refers to the capability of a communication component in means of speed and throughput. • Availability is the term for the probability that a system will perform its specified functions when used under stated conditions. A common mathematical definition of operational availability is Ao = MT BF/(MT BF + MDT), whereas MTBF is the “mean time between failure” and MDT the “mean down time” [2]. However, in this thesis, availability is used in a more general manner, since the basis for mathematical operations is not available.

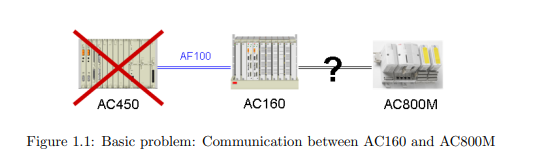

Abstract In order to modernize their infrastructure and keep up with the state of the art, ABB Power Systems decided to replace the older controller AC450 with a new generation of controllers called AC800M. Just like its predecessor, its main task is to work as a sequencer in an otherwise mostly unchanging topology. Although the new controller AC800M provides modern communication features and a sophisticated application development system, it lacks of a communication interface compatible with the residing controllers AC160. A hardware approach addressing this problem is in development, but not available at this point of time. Thus the decision was made to realize the connection using OPC, a widely spread and open software communication interface standard with a high potential of reusability. In addition, it was aimed at gaining additional knowledge about the OPC interface, which is commonly used in industry. In this thesis, we evaluate adequate hardware and software to realize this connection and we have programmed the controllers with applications to evaluate its performance and integrity. In addition, we are making considerations about redundancy that is vital in automation business in order to increase reliability and availability. We have shown that it is possible to interconnect controllers using OPC with satisfactory average performance results. Due to high maximum round trip times and high complexity when realizing redundancy, it is recommended to use such a system for testing purposes or non-critical operational applications, but not for critical systems. In this thesis we also identify and judge several alternative ways of connection.

Acknowledgements First of all, I would like to thank Prof. Dr. Bernhard Plattner of the Computer Engineering and Networks Laboratory TIK at the Swiss Federal Institute of Technology ETH Zurich for supporting and supervising this Master’s Thesis. Special thanks go to my advisors Rainer Baumann and Bernhard Tellenbach of TIK for their straightforward and helpful support during my work. Secondly I would like to thank Dr. Esther Gelle and Pascal Aebli of ABB for enabling this Master’s Thesis in the first place as well as providing aid throughout this thesis. Special thanks also to Stephan Egli for supporting me with the first steps, Swen Woldau for numerous hints concerning AC160 and AF100 as well as Juerg Beck for AC800M tips and tricks. Finally I would like to thank everyone else at PSPD for the provided aid and making my work so convenient not only in a technical but also in a human manner. Baden, June 2007 Martin Pfister

Chapter 1 Introduction This chapter will provide a rough overview of the problem treated by this Master’s Thesis. All technical devices and expressions will be explained more precisely in the next chapter. Please note that since this is a public thesis, it does not contain sensitive company-internal data. 1.1 ABB Power Systems ABB Power Systems is one of the world’s leading providers of infrastructure for controlling combined cycle power stations and waste-to-energy plants. Such a plant control infrastructure includes several hardware parts consisting of controllers, input/output-boards and communication devices as well as many software components to engineer, run, observe and analyze the power plant. A power plant control system has to satisfy a broad variety of different needs, from the efficient and reliable control of the turbines and associated supporting functions (such as lube oil) to easy configuration and operation as well as to sophisticated analysis functions addressing technical and economical aspects. 1.2 Problem Statement Due to high investment costs, the technical management of power plants is a slowgoing business with long life-cycles. Thus, a considerable amount of hardware devices currently in use are tens of years old. For future applications within ABB Power Systems it will be necessary to connect a controller of the newest series used within ABB, Control IT AC800M, with an older controller of the type Advant Controller 160 (AC160). The problem is that these two controllers do not share a fast communication interface of similar type and therefore cannot communicate directly. The standard communication intended for AC160 is Advant Fieldbus 100 (AF100). However, AC800M can support a whole range of buses except for AF100. As a consequence, the communication must be implemented using some relaying technique.

1.2.1 The Use of OPC It was decided in advance to realize the relaying connection using OPC. This solution was chosen because OPC is an open standard and very common in process and automation industry. Furthermore, this solution offers a high potential to be used for similar problems, since a lot of devices support this specification. However, OPC is normally not used for fast controller-to-controller communication but for slower visualization and logging purposes and there is no performance data available for this kind of connection. The use of OPC is therefore both challenging as well as interesting to gain more insights and know-how. It is also to mention that a hardware solution addressing our problem is not available yet. It is therefore necessary to have an alternative way using already available parts, also for testing purposes. 1.3 Goals The goals of this Master’s Thesis are stated as follows: • Setup and evaluation of a test environment • Setup of test systems • Theoretical and practical evaluation of the test systems concerning performance, availability and reliability. • Identification of improvements and different approaches • Comparison with alternatives As a starting point for the performance requirements, the current implementation was taken. The corresponding quantity and type of variables are displayed in Table 1.1 with 32-bit floating point values (floats) as analog in- and outputs and 1-bit boolean values as so-called status and command bits. In the current configuration with AC450 and AC160, all variables are written to the AF100 fieldbus with a cycle time of 256 milliseconds. Therefore we determined the minimum requirement for round-trip times from one controller to the other to exactly this time. In agreement with the advisors, instead of elaborating the optional extension stated in the task description (Appendix C), we spent more time on trying out a

AC160 to AC800M AC800M to AC160 32-bit floats 600 32 1-bit booleans 2200 750 Table 1.1: Requirements for the quantity and type of variables [1] second PROFIBUS approach and the theoretical derivation of a redundancy concept. 1.4 Structure For the reader’s convenience this Master’s Thesis is structured thematically starting with an overview of components and terms (2) in the next chapter. The following chapters inform about the test system setup (3), the evaluations that were made (4) and finally the results (5). In a subsequent chapter the subject redundancy is treated (6) before the thesis comes to an end with the conclusion and outlook (7). Additional information as well as a CD-ROM containing more detailed data is located in the appendix of this thesis

The network function is powerful: The Harbor Network PowerHammer P640 is a carrier-grade router that supports the TCP/IP protocol and features a modular port structure, which is convenient for expansion and maintenance. High-speed transmission: With a transmission rate as high as 10000Mbps, it is suitable for large-scale network environments and can meet the requirements of high bandwidth. Rich interfaces: Equipped with 10G wide area network interfaces and 10G local area network interfaces, as well as RS-232 control ports, it meets various connection requirements. Strong scalability: With 22 expansion slots, it can be flexibly configured according to network requirements. Reliable management functions: Supports multiple network management functions such as CLI, SNMP, and RMON, facilitating network management and monitoring. High security performance: Equipped with VPN and QoS functions, as well as firewall functions, to ensure network security. Stable operating environment: The working temperature range is 0-40℃, and the working humidity is 5%-95%. There is no condensation and it is adaptable to various environments. PM 644 Features High-performance RAID Controller: HighPoint's RocketRAID 644 is the industry's first SATA6Gb/s host adapter that supports RAID5. The data transmission bandwidth has been increased from 3Gb/s to 6Gb/s, and it supports point-to-point connections and is compatible with SATA 3Gb/s and 1.5Gb/s interfaces. Optimized performance: Supports new Native Instruction Sorting (NCQ) serial instructions, targeting audio and video applications that require a large amount of bandwidth. It ensures the synchronization of data transmission and optimizes performance through the NCQ management function. Advanced power management: Equipped with improved power management functions, suitable for energy conservation and efficient operation. Strong compatibility: Fully backward compatible. When new specification products are connected to old specification products, the speed will automatically decrease to 3Gbps or 1.5Gbps. High-speed PCI-E2.0 support: Supports PCI-E2.0, featuring higher transmission efficiency and the newly added dynamic connection function, making it suitable for the demands of data-intensive devices. To sum up, both PM 640 and PM 644 perform well in their respective fields and can meet the demands of different application scenarios.

Precautions regarding Central unit PM 640 and PM 644 (supporting SC 610) mainly include the following points: System security and password Settings Ensure that the password jumper is enabled to protect system security. If the password jumper setting is disabled, the system password will be deleted and the system can be started without a password. The system password can contain up to 32 characters at most and allows the use of numbers and specific special characters. Before installing or removing system components, it is essential to refer to the official installation and service manual to ensure correct operation. Pay attention to the jumper and connector Settings on the system board, such as PWRD_The EN jumper is used to enable or disable the BIOS password function and NVRAM_CLR jumpers are used to retain or clear BIOS configuration Settings. System diagnosis and troubleshooting: Utilize Dell's embedded system diagnostic program to identify system faults and ensure stable system operation. If you encounter problems such as forgetting your password, you can refer to the "Disable Forgotten Passwords" section in the manual to reset the password jumper. If you encounter any problems during use, you can refer to the official documentation or contact Dell technical support for assistance. By following these precautions, the safe and stable operation of the Central unit PM 640 and PM 644 systems can be ensured, and potential problems and risks can be effectively avoided.

ABB Group is a globally leading enterprise in electrical and automation technologies, with its headquarters in Zurich, Switzerland. It is listed and traded on the stock exchanges of Zurich, Stockholm and New York. It was formed by the merger of ASEA of Sweden and BBC Brown Boveri of Switzerland in 1988. The following is a brief introduction to ABB: Business area Electrification: It provides intelligent power solutions from the power generation end to the power consumption end, including medium and low voltage equipment, electric vehicle charging infrastructure, distribution automation, intelligent building technology, etc. Motion Control: As the world's largest supplier of motors and drive systems, we offer high-efficiency motors, frequency converters, generators and intelligent power drive solutions, which are applied in industries such as manufacturing, rail transit and renewable energy. Process Automation: We provide automation control solutions for industries such as energy, mining, chemical engineering, and maritime affairs, helping to enhance production efficiency and energy utilization. Robotics and Discrete Automation: We offer industrial robots, autonomous mobile robots and mechanical automation solutions to help manufacturing enterprises achieve intelligent transformation. ABB Group operates in over 100 countries around the world and has approximately 150,000 employees. In China, ABB has 40 enterprises, 18,000 employees, and its business covers R&D, manufacturing, sales and engineering services, etc. It is one of the top 100 electrical enterprises in China. ABB actively promotes technological research and development and possesses strong innovation capabilities. Its exploration of AI can be traced back to the 1950s, and it has continuously applied new technologies such as artificial intelligence to its products and solutions. We have launched the ABB Ability™ digital platform, providing customers with comprehensive digital solutions from devices to the cloud. ABB is committed to achieving a more sustainable future by helping customers improve energy efficiency, reduce environmental impact and drive social and industrial transformation through its solutions. ABB's relationship with China began in 1907. In 1995, ABB (China) Co., Ltd. was registered in Beijing. It has participated in the construction of many key national projects such as the South-to-North Water Diversion Project, the West-to-East Power Transmission Project, the Qinghai-Xizang Railway, the Beijing Olympics and the Shanghai World Expo. The company has been listed among the Fortune Global 500 for many years and has won numerous industry awards, such as the China Electrical Top 100 List and the China Automation Annual Award. ABB Group, with its outstanding technological strength, extensive product line and profound industry experience, plays a significant role in the global electrical and automation field, constantly driving innovation and development in the industry.

.png)

.png)

.png)