EMERSONFloBoss™ S600+ Flow Computer Instruction Manual

regulations. All installation procedures should be in accordance with

normal practices of good workmanship. Although the S600+ shipped

to you may not include all of the hardware options described in this

manual, the procedure for the basic installation of the unit remains the

same.

Note: We strongly recommend you familiarize yourself with the

procedures described in this chapter before you begin to install

the S600+.

The S600+ uses a modular design that provides maximum flexibility

and ease of installation. The basic panel-mounted version consists of

three major components:

Fabricated metal case, complete with pre-installed PSU/backplane

and four card slots for the modules (a dedicated CPU slot and three

I/O slots).

Removable front panel comprising the LCD display and keypad

assembly.

Plug-in modules. A CPU module and one I/O module are supplied

for a basic configuration; two blank plates are supplied to cover the

unused slots.

Figure 2-1 shows the S600+ system components

Note: User-supplied tools to assist in the installation process may

include a Phillips screwdriver, a regular screwdriver, a small

adjustable spanner wrench, and a 2.5mm Allen key.

2.2 Environmental Considerations

The S600+ panel mounted flow computer is designed for use within

the control room. Place it in a position that provides ease of use,

comfort, and safety for operators and maintenance personnel. The

optimum height for viewing and using the display and keypad is at

operator eye level.

Caution If you install one or more units in a confined space with other heatproducing equipment, give special attention to the combined heating

effect. This combined heat could increase the environmental

temperature beyond its acceptable threshold, thereby impacting

performance.

2.3 Required Tools for Installation

Before you attempt to install the S600+, ensure that you have the

following tools:

Small flat-blade screwdriver suitable for the slot-headed captive

screws on the rear of the case that secure each plug-in board into

the case.

5.5 mm (5 BA) hex or small adjustable wrench for the front panel

bosses

2.5 mm Allen key suitable for the hex cap screw on the front face

of the front panel that secures the front panel molding to the case.

2.4 Installing the S600+

Refer to the following procedures for installing the various S600+

components, including the front panel, panel-mounted unit, and

modules.

2.4.1 Unpacking the S600+

Unpack the S600+ carefully and inspect parts for visual damage.

Note: Do not discard packaging material until after you have

identified all pieces of the shipment and you are confident that

all parts are working correctly.

2.4.2 Removing the Front Panel

To begin the mounting process, remove the front panel from the

S600+:

1. Ensure power has been removed from the S600+.

2. Using a 2.5 mm Allen key, remove the hex cap screw from the

bottom centre of the front panel (refer to Figure 2-2).

Note: A security cap may cover the hex cap screw.

3. Carefully slide the front panel up 4 mm (0.15 in) to allow it to clear

the retaining groove at the top of the case, and then allow the panel

to come forward to clear the panel case completely (refer to Figure

2-3).

Figure 2-3. Lifted Front Panel

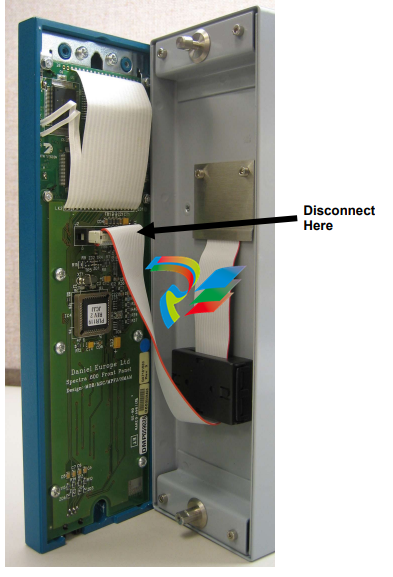

Disconnect the ribbon cable from the back of the front panel at the

blue connector (refer to Figure 2-4). Observe the orientation of the

connector with its mating keyway. You must correctly re-insert the

ribbon cable at the end of the installation process.

Caution Do not remove the ribbon cable from the S600+ housing. This might

damage the S600+. Also, the ribbon cable may also have an EMC

clamp. Be sure to leave it intact without damaging the ribbon cable.

5. Remove the top and bottom bosses from the unit housing, using a

5.5 mm (5 BA) hex wrench.

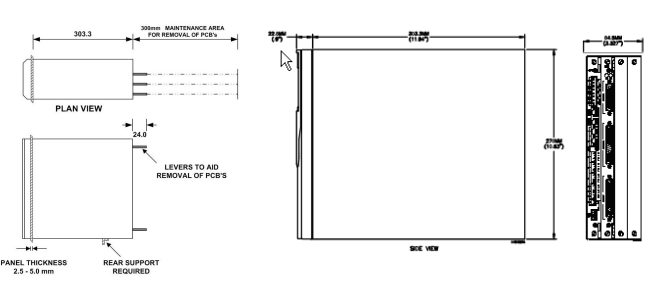

Table 2-1. Mounting Dimensions

Part Dimensions

Display Keypad Molding 85 mm (3.35") width x 269 mm (10.59") height x 28 mm (1.10") deep

Case 84.5 mm (3.327") width x 270 mm (10.63") height x 303.8 mm (11.94")

deep

Panel Cutout 66 mm (2.6") width x 150 mm (5.9") height

Pitch Between Cases 110 mm (4.33") giving 25 mm (0.98") air gap

Max Panel Thickness 10 mm (0.39")

Access Allow 300 mm (11.81") clearance directly behind case for maintenance

2.4.3 Installing the Panel-Mounted Unit

After removing the front panel, install the panel-mounted unit:

1. Keeping environmental considerations in mind, construct the

framework of the cubicle to support the operating panel.

Note: A standard 483 mm (19 in) rack that is 311 mm (12.25 in)

high can accommodate up to four S600+s provided you

support the rear of the case.

2. Refer to Figure 2-6 and Table 2-1 for position details for two 7 mm

(0.276 in) holes and a cutout. The panel cutout should be

.png)

.png)

.png)