HoneywellEXPERION PKSSeries C I/O User's Guide EPDOC-X126-en-A November 2019

l On board excitation power (no need for marshalling power)

l Direct / Reverse Input Indication

Galvanic isolation

Direct Output

bussed 24Vdc

l Extensive self-diagnostics

l Functional redundancy

l Output direct/reverse

l Safe-state (FAILOPT) behaviors

l Each channel can be configured to HOLD, LAST, VALUE, or

SHED to a SAFE VALUE.

l Fuse-less short circuit protection

allows a short circuit to exist without blowing any fuses. When a particular

channel is shorted, internal circuits detect this and remove power to the

I/O

module/IOTA

Feature/function

field connection. The channel remains de-energized until the short circuit

is repaired

l Latched, pulsed or pulse-width modulated output

l Galvanic isolation

l Output read back checking to screw terminal

Digital Output -

Relay IOTA

l Galvanic isolation

l Counter EMF snubbing circuit

l Isolated dry contact (Form A or B)

l Output read back checking on system side of driver

Low Level

Analog

(temperature)

Input - LLMUX

l TC and RTD operation

l Remote cold junction capability

l 1 Second PV scanning with OTD protection

l Configurable OTD protection (See below)

l Temperature points can be added in 16 point increments

Low Level

Analog

(temperature)

Input - LLAI

l Thermocouple (TC) and RTD operation

l 1 Second PV scanning with Open Thermocouple Detection (OTD)

protection

l Configurable OTD protection

Speed

Protection

Module - SP

l Supports 2/3 voting logic for speed and acceleration.

l Supports multiple configurable trip limits for speed and acceleration.

Servo Valve

Positioner

Module - SVPM

l Supports PID execution and position calibration.

l Computes valve position from LVDT/RVDT input signal and controls valve

by signaling the Servo coil.

l Provides current modulation to avoid stiction in controlled device (servo

valve).

Pulse Input

Module - PIM

l Highly accurate frequency/period calculations.

l Supports Dual Pulse Integrity in accordance with ISO6551:1996 Level A for

custody transfer applications.

l Extensive self-diagnostics.

l Functional redundancy.

l Provides channel-to-channel and terminal block to backplane voltage

isolation.

Universal

Input/Output

Module - UIOM

l Extensive self-diagnostics

l Optional redundancy

l Independently configurable I/O channels

l controls DI, AI, DO, AO

l HART capable, multivariable instruments

l PV protection through a broken-wire detection diagnostic

l Safe-state (FAILOPT) behaviors

l Supports multiple channel configurations

UIO-2

I/O

module/IOTA

Feature/function

In addition to all features supported by UIO, the UIO-2 supports the folowing

additional features:

l Provides one HART modem per I/O channel

l Supports pulse counting on up to four of any of the 32 channels

configured as DI

l Supports DO ganging within the following eight channel number groups: 1

- 4, 5 - 8, 9 - 12, 13 - 16, 17 - 20, 21 - 24, 25 - 28, and 29 – 32. However,

ganging across these groups is NOT possible

Beginning with ExperionR501, the following new features are available:

l Supports SOE on any channel

l Supports NAMUR inputs. This function, however, will require external

voltag

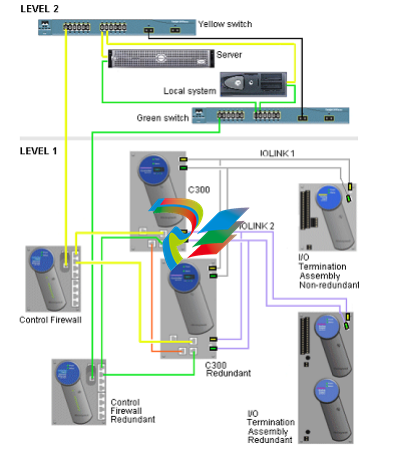

Series C I/O and C300/CN100 topology

ATTENTION

Topology for the Series C I/O and C300 - 20mS CEE Controller is similar to the Series C I/O

and C300 - 50ms Controller, with the exception that the C300 - 20mS CEE Controller does

not support the PMI/Os. CN100 supports all the Series C family of I/Os with the exception of

SPM and SVPM.

Series C I/O is attached to an IOLINK that is being mastered by a C300 controller. It is important to

note that:

l IOLINK - Serves as data repository for IOM function blocks in Control Builder to provide

communications interface with Series C I/O.

l Series C I/O cannot reside on an IOLINK mastered by an IOLIM or xPM.

Examining the topology rules

The following are the topology rules relating to the Series CI/O environment.

Refer to the following document for graphical representations of cabinet layouts depicting Series

C, PMIO, FIM, and LLMUX hardware configurations. Control Hardware Planning Guide

Item Impact Description

Redundancy None Redundancy capacity and performance is displayed while

redundancy is present.

Switchover Same as PM

I/O

Series C I/O hardware and/or software can switchover, recover,

and resume full view in a timeframe no greater than PM I/O.

Initialization All Series C I/O

per

C300/CN100

Can be initialized in 60 seconds (+/- 25%) after cabinet-level loss

power loss.

I/O module Can be initialized in 10 seconds (+/- 25%) after IOM level loss

power loss.

Multiple I/O

Links

2 Design allows the use of multiple Series C I/O Links in the same

cabinet.

tem Impact Description

I/O Link

performance

None I/O Link networks perform at the current distance and IOP count

specifications.

I/O Link

capacity

40 max Maximum of 40 redundant IOMs per link

(for either Series C I/O or PM I/O).

IOMs / C300 64 max Maximum of 64 redundant IOMs per C300 (for PM I/O).

80 max Maximum of 80 redundant IOMs per C300 (for Series C I/O).

Series C and

PM I/O -

combined

64 Design supports Series C and PM I/O FTAs in the same side of the

cabinet. Current configuration prevents IOTA and FTAs in the

same column.

I/OMs/CN100 40 Max Maximum of 40 redundant I/OMs per CN100

3.3 Supported Series C I/O modules

The list of I/O modules below can be used on a Series C IOLINK. The IOLINK contains a function

.png)

.png)

.png)