EMERSONAMS Suite: Machinery Health™ Manager

Getting started

Topics covered in this chapter:

• Customized installation media

• Where to get help

• Installation Types

• Operating Requirements

Thank you for choosing AMS Machinery Manager. Let's get started!

Your AMS Machinery Manager package includes:

□ Quick Start Guide

□ Software Installation DVD

□ Manuals DVD

1.1 Customized installation media

Based on your order, the Software Installation DVD contains the following:

• Standalone (Single User) or Network installation

• AMS Machinery Manager technologies

• Number of licensed users

To add a technology or more licensed users, contact your Emerson Process Management

Sales Representative

Installation Types

There are two main types of AMS Machinery Manager installations:

• Standalone (or Single-user standalone)

• Network (or Single-user network and Multiple-user network).

1.3.1 Standalone installation

A Standalone system allows you to use periodic technology with one computer and CSI

Machinery Health Analyzers. A standalone installation indicates you have a single copy of

AMS Machinery Manager with a single serial number on one computer.

You can install these components:

• AMS Machinery Manager

• AMS Standalone Data Transfer (on a different computer)

• AMS Machinery Manager ODBC Driver

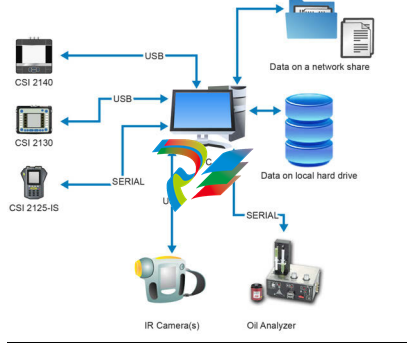

Figure 1-1: Standalone system example

This example does not attempt to show all supported hardware options.

Network installations

A network system allows you to use online technology and periodic technology. AMS

Machinery Manager communicates with a CSI Machinery Health Monitor using a network

connection. A network system is deployed on a local area network (LAN) or a wide area

network (WAN).

You can install these components:

• AMS Machinery Manager

• Online Server

• Secondary Database Server

• Data Import Server

• AMS Machinery Manager Data Import Client

• AMS Standalone Data Transfer (on a different computer)

• AMS Machinery Manager ODBC Driver

• Machine History Viewer

• Collaboration Tool

• CSI Data Provide

Single-user and multiple-user LAN

A Single-user network indicates you have a Network Server and a Client installed on one

computer and have one serial number. Single-user network allows the Client to be

installed on other computers in the network. However, only one user can log in at a time.

This installation is used for single user customers with an online system.

A Multiple-user network indicates you have a Network Server and a Client installed on a

server-class computer, and the Client installed on other computers in the network.

Multiple users can log in at the same time.

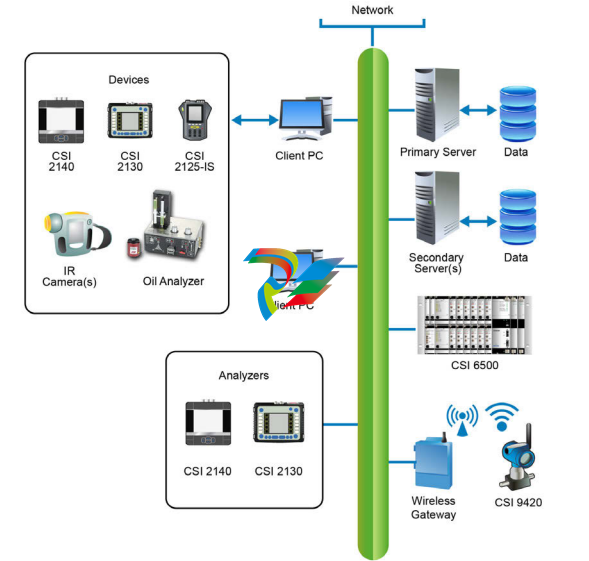

Figure 1-2: Local area network system example

This example does not attempt to show all supported hardware or configuration options.

Multiple-user WAN

The WAN system is designed to allow remote AMS Machinery Manager users to load,

dump, and view data over wide area networks, such as private networks, virtual private

networks(1), or the Internet.

Figure 1-3: Wide area network system example

This example does not attempt to show all supported hardware or configuration options.

Localization considerations

You may license AMS Machinery Manager software in English or a localized (translated)

version. You must specify a language at the time you purchase your software licenses.

Only the language you license will be on your software installation DVD. Follow these

guidelines when preparing to install a localized version of AMS Machinery Manager.

Note

You may need to change your computer name before installing AMS Machinery Manager. A valid

computer name can have numbers 0-9, uppercase and lowercase letters A-Z, and the hyphen (-).

Special characters (< > ; : " * + = | ? ,), accented characters, and other multibyte characters in a

computer name can cause problems and interfere with a successful installation of AMS Machinery

Manager software. Computer names cannot have only numbers, nor can they contain spaces.

Windows 7 Professional, Windows 7 Enterprise, Windows Server 2008, and Windows

Server 2012

Recommendations for Windows without Multilingual User Interface (MUI) support, for

example: Microsoft Windows 7 Professional, Windows 7 Enterprise, Windows Server 2008,

and Windows Server 2012.

• Installing localized AMS Machinery Manager is supported on a Windows system of

the same language with default regional settings. For example, install AMS

Machinery Manager (German) on Windows (German).

• Installing localized AMS Machinery Manager on an English Windows system is not

recommended. If you install localized AMS Machinery Manager on Windows

(English), text may not display properly.

• When you upgrade AMS Machinery Manager, the language must match the

currently installed AMS Machinery Manager language. For example, update AMS

Machinery Manager v5.51 (German) to AMS Machinery Manager v5.6 (German). To

change the AMS Machinery Manager language you need a full installation instead of

an upgrade.

• Avoid changing Windows regional settings. Changes may cause unexpected

behavior in AMS Machinery Manager.

• Installing English AMS Machinery Manager on a non-English Windows system is

supported for Windows (Japanese) only.

Windows 8.1, Windows 8, and Windows 7 Ultimate

Recommendations for Windows with Multilingual User Interface (MUI) support, for

example: Microsoft Windows 8.1, Windows 8, and Windows 7 Ultimate.

• Installing localized AMS Machinery Manager on a Windows system where the

matching language pack and regional settings have already been installed. For

example, install AMS Machinery Manager (German) on Windows after installing the

German language pack.

• When you upgrade AMS Machinery Manager, the language must match the

currently installed AMS Machinery Manager language. For example, update AMS

Machinery Manager v5.51 (German) to AMS Machinery Manager v5.6 (German). To

change the AMS Machinery Manager language you need a full installation instead of

an upgrade.

• One language of AMS Machinery Manager is available per installation. If you change

your regional settings or language pack after installing AMS Machinery Manager,

strings may not display properly. Use the regional settings and language pack that

match the language you licensed for AMS Machinery Manager.

AMS Machinery

Manager language

Windows language

edition Windows regional settings Supported

Localized version MUI with language pack settings match language pack Yes (preferred)

Localized version MUI with language pack English No (translated strings may

not display correctly)

Standalone installation

Topics covered in this chapter:

• Install AMS Machinery Manager

• Launch AMS Machinery Manager

• Update or repair the installation

2.1 Install AMS Machinery Manager

Prerequisites

Verify the client computer meets the operating requirements for a workstation.

If you are upgrading your software, back up your database before completing the software

update. Your databases require reindexing to work with the new software. If you need to

reinstall the previous version of software, be aware that any database you open with the

new software will be reindexed and will no longer work with any previous version.

Procedure

1. Log on to the computer as a user with administrator rights.

2. Insert the AMS Machinery Manager Software Installation DVD and open it in

Windows Explorer.

3. Run RBMsetup.exe.

Important

On Windows 7 and Windows Server 2008, right-click RBMsetup.exe and select Run as

administrator. Click Cancel if the installation launches automatically when you insert the DVD.

You must run the installation manually.

4. If a prompt to install Microsoft .NET Framework 4.0 appears, choose to install this

software and allow the system to reboot, (if required).

The AMS Machinery Manager installation begins automatically after reboot.

5. Accept the license agreement and click Next.

6. At the ATTENTION!! dialog, click Yes if you are installing the software for the first

time. If you are upgrading your software, this is a reminder to stop the installation

and back up your database first. Click No to stop the installation.

7. The setup program verifies that your system meets the minimum requirements. If

they are met, the Options page dialog appears. If they are not met, a message

displays more information. Update the computer to meet the requirements or

contact Product Support.

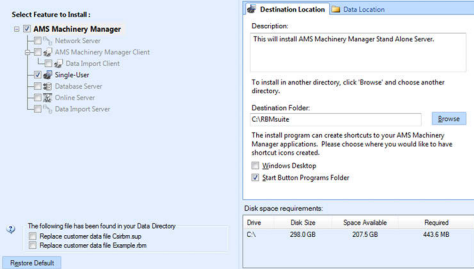

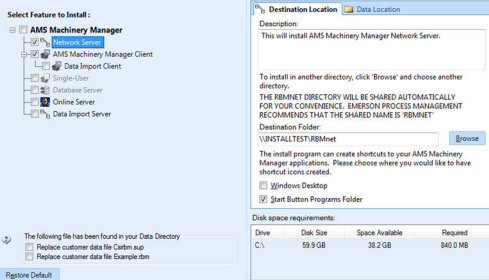

8. (Optional) At the Select Features to Install pane, you can change defaults for your

installation.

Notes

• Use the default settings and directory names unless there is a particular reason to change

them. Using the defaults results in a trouble-free installation and streamlined interaction

with Emerson Product Support, should a problem ever arise.

• If you are updating the software, this screen also displays the message, “The following file

has been found in your Data Directory” followed by file names. You can check the box by

the file to overwrite the file.

• If you are updating your software, some fields may be disabled. If you want to update your

software and move to a different computer, contact Emerson Product Support.

9. Click Install to start the installation.

The Installing Components screen displays and shows the status of the installation.

Note

Once the install is underway, there will be a point where the Cancel button is disabled. Do not

try to end the install if the Cancel button is disabled. If the install aborts after this point, you

may need to contact Emerson Product Support.

10. If you are using Windows Firewall, grant access to programs published by Emerson

Process Management when prompted.

11. Continue through the installation steps and follow prompts.

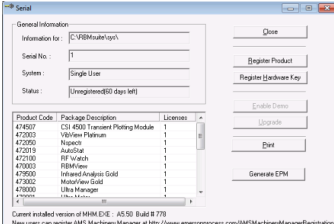

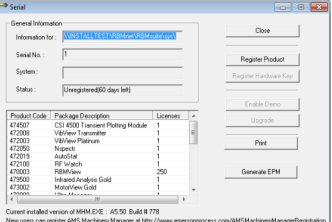

12. When the Serial dialog appears, click Register Product to register the software now, or

click Close to skip registration.

Note

To register later, open Windows Explorer, go to C:RBMsuitesys and double-click Serial.exe.

a. In the Serial dialog, click Register Product.

The Register Product dialog appears. You need the Serial No. and Request No.

during registration.

b. Contact Product Support to register.

Phone: Toll free 888.367.3774, option 2 (U.S. and Canada)

+63.2.702.1111 (Rest of world)

Email: wwcs.custserv@AP.EmersonProcess.com

Web: http://www.mhm.assetweb.com/reg

c. Enter the Response code given to you by a Product Support representative.

d. Click OK.

The Register Product dialog closes.

e. In the Serial dialog, verify the Status is "Registered."

f. Click Close.

Your software is registered.

The installation automatically continues.

13. On the Finish page, click Finish to complete the installation.

If the computer requires a reboot, Restart Now is selected on the Finish page. Allow

the system to reboot before attempting to run the software.

Launch AMS Machinery Manager

Now that you have installed and registered AMS Machinery Manager, you are ready to

launch AMS Machinery Manager.

Procedure

1. Go to Start > Programs (All Programs) > AMS Machinery Manager.

2. Select AMS Machinery Manager.

3. Log in when prompted.

a. Initially, Administrator is the default user. Leave the password blank and click OK.

b. If you use a different user, enter the username and password and click OK.

See the Administration topics in AMS Machinery Manager Help to set the

Administrator password and create a new user.

2.3 Update or repair the installation

Note

You must register the software when you update the software.

Prerequisites

Close all AMS Machinery Manager programs.

Stop AMS Machinery Manager services.

Procedure

1. Insert the AMS Machinery Manager Software Installation DVD and open it in

Windows Explorer.

2. Run RBMsetup.exe.

Important

On Windows 7 and Windows Server 2008, right-click RBMsetup.exe and select Run as

administrator. Click Cancel if the installation launches automatically when you insert the DVD.

You must run the installation manually.

3. At the startup screen choose Add/Update or Repair and click Next.

4. At the Options pane, choose the features to install or leave the defaults selected for

an update.

5. In the list labeled The following files have been found in your Data Directory, check the box

by a file to replace the file on your computer with the file from the installation.

6. Click Install to start the installation.

The Installing Components screen displays the status of the installation.

Note

Once the install is underway, there will be a point where the Cancel button is disabled. Do not

try to end the install if the Cancel button is disabled. If the install aborts after this point, you

may need to contact Emerson Process Management Product Support.

7. Continue through the installation steps and follow prompts.

8. On the Finish page, click Finish to complete the installation.

If the computer requires a reboot, Restart Now is selected on the Finish page. Allow

the system to reboot before attempting to run the software.

Network installation

Topics covered in this chapter:

• Network installation overview

• Install the Network Server

• Install the AMS Machinery Manager Client

• Launch AMS Machinery Manager Client

• Install a Secondary Database Server

• Install an Online Server

• Install Data Import Server and Data Import Client

• Install Collaboration Tool

• Update or install new features on the Network Server

3.1 Network installation overview

Important

• If you intend to install Machine History Viewer or CSI Data Provider, you must install Internet

Information Services before installing AMS Machinery Manager. The AMS Machinery Manager

installation makes important changes to the IIS setup that you would otherwise have to

configure manually with the assistance of Product Support.

• If you are upgrading your software, back up your database before completing the software

update. Your databases require reindexing to work with the new software. If you need to

reinstall the previous version of software, be aware that any database you open with the new

software will be reindexed and will no longer work with any previous version.

Prerequisites

Ensure each computer meets the minimum system operating requirements.

Procedure

1. Install the Network Server on the server first.

2. Install the AMS Machinery Manager Client on a workstation.

3. Install secondary servers and clients on other computers on the network.

You can install Online Server, Secondary Database Server, Data Import Server, Data

Import Client, and AMS Machinery Manager Client on other computers in the

network.

Postrequisites

• Configure service accounts and firewall settings for each computer, if necessary.

Refer to Chapter 6 for more information.

Network installations require further configuration for each CSI Machinery Health

Monitor.

For more information, open Help in AMS Machinery Manager and choose

Administration > Online Server.

3.2 Install the Network Server

The Network Server installation procedure installs and configures the programs and

services required for the primary server. You can choose to install additional features.

The installation creates a shared folder from which you install the Client or other licensed

components on other machines on this network. By default, the folder is C:RBMnet and is

shared as \ServernameRBMnet where Servername is the network computer name.

Prerequisites

Ensure the computer meets the minimum system operating requirements.

If you are upgrading your software, back up your database before completing the software

update. Your databases require reindexing to work with the new software. If you need to

reinstall the previous version of software, be aware that any database you open with the

new software will be reindexed and will no longer work with any previous version.

To install AMS Machinery Manager on a drive other than C, create a shared folder named

RBMnet on the drive where you want to install the software, prior to starting the

installation. After installation is complete, an administrator may need to modify the shared

folder's security permissions to allow access from other computers.

Important

If you intend to install Machine History Viewer or CSI Data Provider, you must install Internet

Information Services before installing AMS Machinery Manager. The AMS Machinery Manager

installation makes important changes to the IIS setup that you would otherwise have to configure

manually with the assistance of Product Support.

Procedure

1. Log on to the computer as a user with administrator rights.

2. Insert the AMS Machinery Manager Software Installation DVD and open it in

Windows Explorer.

3. Run RBMsetup.exe.

Important

On Windows 7 and Windows Server 2008, right-click RBMsetup.exe and select Run as

administrator. Click Cancel if the installation launches automatically when you insert the DVD.

You must run the installation manually.

4. Accept the license agreement and click Next.

If a prompt to install Microsoft .NET Framework 4.0 appears, choose to install this

software and allow the system to reboot, (if required).

The AMS Machinery Manager installation begins automatically after reboot.

6. At the ATTENTION!! dialog, click Yes if you are installing the software for the first

time. If you are upgrading your software, this is a reminder to stop the installation

and back up your database first. Click No to stop the installation.

7. The setup program verifies that your system meets the minimum requirements. If

they are met, the Options page dialog appears. If they are not met, a message

displays more information. Update the computer to meet the requirements or

contact Product Support.

8. At the Options page dialog, make changes to the Select Features to Install list, if

desired.

Network Server and Client are checked as the preferred defaults. You can select

other features, if available. Refer to corresponding sections for more information

about additional features.

• Database Server, Section 3.5

• Online Server, Section 3.6

• Data Import Server, Section 3.7

• Data Import Client, Section 3.7

Notes

• Use the default settings and directory names unless there is a particular reason to change

them. Using the defaults results in a trouble-free installation and streamlined interaction

with Emerson Product Support, should a problem ever arise.

• If you are updating the software, this screen also displays the message, “The following file

has been found in your Data Directory” followed by file names. You can check the box by

the file to overwrite the file

• If you are updating your software, some fields may be disabled. If you want to update your

software and move to a different computer, contact Emerson Product Support.

Follow these steps if you need to change the default locations:

a. If you need to change the installation directory, select Network Server in the

features list and open the Destination Location tab.

Browse to the location. The Destination Folder is in Universal Naming Convention

(UNC) format. A red error icon flashes if the path is invalid.

b. If you need to change where your data is stored, select Network Server in the

features list and open the Data Location tab.

Browse to the location. The path is in Universal Naming Convention (UNC)

format. A red error icon flashes if the path is invalid.

9. Click Install to start the installation.

The Installing Components screen displays the status of the installation.

Note

Once the install is underway, there will be a point where the Cancel button is disabled. Do not

try to end the install if the Cancel button is disabled. If the install aborts after this point, you

may need to contact Emerson Process Management Product Support.

10. If you are using Windows Firewall, grant access to programs published by Emerson

Process Management when prompted.

11. When the Serial dialog appears, click Register Product to register the software now, or

click Close to skip registration

Note

To register later, on the Network Server, go to C:RBMnetRBMsuitesys and double-click

Serial.exe.

The Register Product dialog appears. You need the Serial No. and Request No.

during registration.

b. Contact Product Support to register.

Phone: Toll free 888.367.3774, option 2 (U.S. and Canada)

+63.2.702.1111 (Rest of world)

Email: wwcs.custserv@AP.EmersonProcess.com

Web: http://www.mhm.assetweb.com/reg

c. Enter the Response code given to you by a Product Support representative.

The code is only valid for your computer.

d. Click OK.

The Register Product dialog closes.

e. In the Serial dialog, verify the Status is "Registered."

f. Click Close.

Your software is registered.

The installation automatically continues, installing the Client and any other selected

features.

12. Continue through the installation steps and follow prompts.

13. On the Finish page, click Finish to complete the installation.

If the computer requires a reboot, Restart Now is selected on the Finish page. Allow

the system to reboot before attempting to run the software.

Postrequisites

Install AMS Machinery Manager Client on a workstation.

3.3 Install the AMS Machinery Manager Client

Run the AMS Machinery Manager installation program (RBMsetup.exe) on a computer in

the AMS Machinery Manager network. Choose the Client option.

Prerequisites

• Install the AMS Machinery Manager Network Server on the server first.

• Verify the client computer meets the operating requirements for a workstation.

• Verify the workgroup or domain settings match on the Network Server computer

and Database Server computer.

Procedure

1. Log on to the computer as a user with administrator rights.

Browse to the shared folder on the Network Server. For example, \Servername

RBMnet, where Servername is the computer's name.

Important

Do NOT use a mapped drive path.

3. Run RBMsetup.exe.

Important

On Windows 7 and Windows Server 2008, right-click RBMsetup.exe and select Run as

administrator. Click Cancel if the installation launches automatically when you insert the DVD.

You must run the installation manually.

4. At the Options page dialog, make changes to the Select Features to Install list, if

desired.

You can install certain additional features on other computers in the AMS Machinery

Manager network. The Network Server option is disabled here since only one

network server is allowed on an AMS Machinery Manager network.

The Client is selected and default locations are set. If desired, select the Shortcuts tab

and select Add shortcuts to desktop

5. Click Install to start the installation.

The Installing Components screen displays the status of the installation.

Note

Once the install is underway, there will be a point where the Cancel button is disabled. Do not

try to end the install if the Cancel button is disabled. If the install aborts after this point, you

may need to contact Emerson Process Management Product Support.

6. Continue through the installation steps and follow prompts.

7. On the Finish page, click Finish to complete the installation.

If the computer requires a reboot, Restart Now is selected on the Finish page. Allow

the system to reboot before attempting to run the software.

Launch AMS Machinery Manager Client

Now that you have installed and registered AMS Machinery Manager, you are ready to

launch the AMS Machinery Manager Client.

Procedure

1. Go to Start > Programs (All Programs) > AMS Machinery Manager.

2. Select AMS Machinery Manager Client.

3. Log in when prompted.

a. Initially, Administrator is the default user. Leave the password blank and click OK.

b. If you use a different user, type in the username and password and click OK.

See the Administration topics in AMS Machinery Manager Help to set the

Administrator password and create a new user.

3.5 Install a Secondary Database Server

Prerequisites

• Install the AMS Machinery Manager Network Server on the server first.

• Verify the workgroup or domain settings match on the Network Server computer

and Database Server computer.

Procedure

1. Log on to the computer as a user with administrator rights.

2. Browse to the shared folder on the Network Server. For example, \Servername

RBMnet, where Servername is the computer's name.

Important

Do NOT use a mapped drive path.

3. Run RBMsetup.exe.

Important

On Windows 7 and Windows Server 2008, right-click RBMsetup.exe and select Run as

administrator. Click Cancel if the installation launches automatically when you insert the DVD.

You must run the installation manually.

4. Follow instructions presented by the installation program.

5. Accept the license agreement and click Next.

6. At the ATTENTION!! dialog, click Yes if you are installing the software for the first

time. If you are upgrading your software, this is a reminder to stop the installation

and back up your database first. Click No to stop the installation.

7. At the Options page dialog, make changes to the Select Features to Install list, if

desired.

You can install certain additional features on other computers in the AMS Machinery

Manager network. The Network Server option is disabled here since only one

network server is allowed on an AMS Machinery Manager network.

• To install a Secondary Database server, select Database Server.

• (Optional) To install the Client, select Client.

• Uncheck features you do not want to install on this computer.

You can change the default destination location and configuration location on your

database server. These tabs are disabled for updates.

8. Click Install to start the installation.

The Installing Components screen displays the status of the installation.

Note

Once the install is underway, there will be a point where the Cancel button is disabled. Do not

try to end the install if the Cancel button is disabled. If the install aborts after this point, you

may need to contact Emerson Process Management Product Support.

9. Continue through the installation steps and follow prompts.

10. On the Finish page, click Finish to complete the installation.

If the computer requires a reboot, Restart Now is selected on the Finish page. Allow

the system to reboot before attempting to run the software.

The secondary database server can be accessed through the Network Server. The files are

installed in C:RBMDBSRV by default.

Postrequisites

• In Windows Explorer, browse to C:RBMDBSRV and create new folder named CustData.

Share the CustData folder so it is available on the AMS Machinery Manager network.

• Add the database server in RBM Network Administration. Refer to the Administration

topics in AMS Machinery Manager Help for more information.

3.6 Install an Online Server

Note

Unless otherwise specified, a CSI Machinery Health Monitor is pre-configured with a database

created according to customer specifications. The Online Server has been set up during

commissioning.

You can install additional Online Servers and commission additional CSI Machinery Health

Monitors on your AMS Machinery Manager network. If you install an additional Online

Server, select Database Server as well.

Prerequisites

• Install the AMS Machinery Manager Network Server on the server first.

• Verify the workgroup or domain settings match on the Network Server computer

and Database Server computer.

Procedure

1. Log on to the computer as a user with administrator rights.

Browse to the shared folder on the Network Server. For example, \Servername

RBMnet, where Servername is the computer's name.

Important

Do NOT use a mapped drive path.

3. Run RBMsetup.exe.

Important

On Windows 7 and Windows Server 2008, right-click RBMsetup.exe and select Run as

administrator. Click Cancel if the installation launches automatically when you insert the DVD.

You must run the installation manually.

4. Follow instructions presented by the installation program.

5. At the AMS Machinery Manager Setup - Options page, select Online Server and

Database Server.

• (Optional) To install the Client, select Client.

• Uncheck features you do not want to install on this computer.

6. Continue through the installation steps and follow prompts.

7. In Windows Services, verify the following services are started.

• CsiO_Server

• CsiMtdbMgr

• CSI_MhmRemote

Postrequisites

• In Windows Explorer, browse to C:RBMDBSRV and create new folder named CustData.

Share the CustData folder so it is available on the AMS Machinery Manager network.

• Set up the Online Server in RBM Network Administration. Refer to the Administration

topics in AMS Machinery Manager Help for more information.

3.7 Install Data Import Server and Data Import

Client

The Data Import Server and Data Import Client are only available if you license the Data

Import functionality (included with network systems). You can install Data Import Server

and Data Import Client together or separately on the Network Server or on other

computers in the AMS Machinery Manager network.

Install Data Import Server or Client on an existing

Network Server

Follow instructions to update or install new features on the Network Server. See

Section 3.9. At the Options pane, choose the Data Import Server and/or Data Import Client.

If you choose Data Import Client, AMS Machinery Manager Client is automatically selected.

Data Import Client is required to be installed in the same directory as the AMS Machinery

Manager Client.

3.7.2 Install Data Import or Client on a Secondary Server or

Workstation

Prerequisites

• Ensure the computer meets the minimum system operating requirements.

• Verify the workgroup or domain settings match on the Network Server computer

and Database Server computer.

Procedure

1. Log on to the computer as a user with administrator rights.

2. Browse to the shared folder on the Network Server. For example, \Servername

RBMnet, where Servername is the computer's name.

Important

Do NOT use a mapped drive path.

3. Run RBMsetup.exe.

Important

On Windows 7 and Windows Server 2008, right-click RBMsetup.exe and select Run as

administrator. Click Cancel if the installation launches automatically when you insert the DVD.

You must run the installation manually.

4. Accept the license agreement and click Next.

5. At the Options pane, choose the Data Import Server and/or Data Import Client.

If you choose Data Import Client, AMS Machinery Manager Client is automatically

selected. Data Import Client is required to be installed in the same directory as the

AMS Machinery Manager Client.

6. Click Install to start the installation.

The Installing Components screen displays the status of the installation.

Install Collaboration Tool

When Collaboration Tool is installed with AMS Machinery Manager Network Server and

Clients, users logged into the Clients using the same Network Server can communicate

with one another and share multiple types of information with other Collaboration Tool

users.

3.8.1 Install Collaboration Tool on the Network Server

When you install Collaboration Tool on the Network Server the MHM Peer Resolver Service

(MHMPeerResolverService.exe) is installed.

Prerequisites

• Install the AMS Machinery Manager Network Server on the server first.

• Install AMS Machinery Manager Client on the Client computer.

Procedure

1. On the Network Server, use Windows Explorer to browse to the RBMnet folder. For

example, C:RBMnet.

2. Browse to InstallCollaborationTool.

3. Double-click setup.exe and continue through the installation.

Important

On Windows 7 and Windows Server 2008, right click setup.exe and select Run as administrator.

4. Accept the license agreement and click Next.

5. Click Install to start the installation.

The Installing Components screen displays the status of the installation.

Note

Once the install is underway, there will be a point where the Cancel button is disabled. Do not

try to end the install if the Cancel button is disabled. If the install aborts after this point, you

may need to contact Emerson Process Management Product Support.

.png)

.png)

.png)