EMERSONOvation® Expert Transitionfor Siemens Teleperm XP Control Systems

Ovation® Expert Transition

for Siemens Teleperm XP Control Systems

Transition to Better Controls From

a Better Supplier

Today’s competitive business environment requires optimal

performance not only from your power plant generation

equipment, but also from your operations and maintenance

personnel.

Are you currently experiencing any of the following Teleperm XP

control system issues that may be prohibiting your plant from

optimal operations?

• Poor performance and reliability

• Multiple systems for a single power block

• Limited system-to-system communication

• Inadequate product service and support

• High support costs from outdated technology

• Considering TXP replacement after only 3-5 years in service

If yes, then you need a supplier with vast power industry expertise

that can provide performance-enhancing technology combined

with comprehensive support to optimize your plant operations.

That supplier is Emerson.

Are you ready to experience increased satisfaction with better

controls and award-winning support services? If so, then make

the transition to Emerson and discover why we are the leaders

in power generation controls and automation with a full suite

of products and services.

Use Today’s Technology While Preserving

Yesterday’s Investments

Transition your Teleperm XP control systems to proven Ovation

technology for enhanced turbine operations. Emerson migration

programs have been proven to reduce project costs and improve

plant operations in hundreds of installations on various control

system platforms, even those from other vendors.

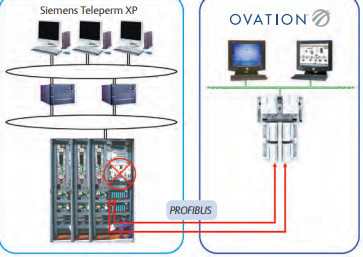

Key to our transition strategy is an integrated Ovation Profibus®

DP I/O module that interfaces directly to the Profibus DP

communication network used in the Teleperm XP system to

connect with the ET200M I/O. Our solution provides your

operators complete control and monitoring capabilities from

a single Ovation system, without starting over. Your transition

choices include retaining your existing I/O, terminations, and

field wiring – or migrating your entire legacy TXP system to

Ovation for a complete technology upgrade.

Emerson’s transition program includes a total replacement of the

embedded Teleperm XP SIMADYN system with native Ovation

turbine I/O modules, enabling quicker response times and tighter

controls. Our turbine I/O was designed specifically to handle

unique control requirements such as turbine speed pickups, fast

closed-loop positioning of major servo-operated valves, and

interfacing to electro-hydraulic servo valve actuators.

Use of fully-redundant I/O interface modules and high-speed

Ovation Controllers, with proven logic such as 2-out-of-3 testable

manifolds assures the highest level of reliability, performance, and

safety for your demanding gas and steam turbine operations.

Ovation® Expert Transition

for Siemens Teleperm XP Control Systems

® Siemens Teleperm XP

The Emerson solution:

• Retains your existing Teleperm XP I/O

• Reuses existing terminations and associated wiring

• Replaces the entire TXP SIMADYN sub-system with

fully integrated Ovation Turbine I/O modules

• Includes full support for turbine OEM control-related

Product Modifications (Prod Mods)

“Great service, teamwork, and cooperation are the benchmarks of your organization, but

I believe that the Emerson team at Dunkirk exceeded even those expectations on a daily basis.”

— Bill Vogel, Instrumentation & Controls Supervisor, Dunkirk Power Plant, NRG

Put Decades of Turbine Expertise to Work

for You

Our Emerson’s transition strategy is based on a 40-year

foundation of engineering, installing, and servicing new and

retrofitted turbine controls around the world. Over 30 of those

years includes experience as the primary gas and steam turbine

control supplier for units provided by the former Westinghouse

Power Generation Business Unit (PGBU).

Emerson has designed and manufactured numerous turbine

control platforms and associated control applications. Our

tradition of supplying innovative, industry-leading turbine

solutions is unmatched in the automation market.

Emerson’s dedicated turbine control group includes highly

specialized experts who have years of experience with turbines

from every major OEM, including Westinghouse, Siemens,

GE, ABB, and more. Our engineers possess the knowledge

and capabilities to help you incorporate turbine OEM Product

Modifications into your control system.

Emerson’s turbine control solutions combine state-of-the-art

technology, excellent project implementation, and dedicated

customer service to provide you with maximum availability

today, tomorrow, and in the years to come — so you get the best

performance out of your existing assets while extending life cycle.

The Emerson Advantage

• Low-risk, U.S.-based Provider

Emerson, headquartered in St. Louis, Missouri, is a recognized

.png)

.png)

.png)