ABBMark* VIe and Mark VIeS Control Systems Volume I: System Guide

Safety Symbol Legend

Control System Warnings

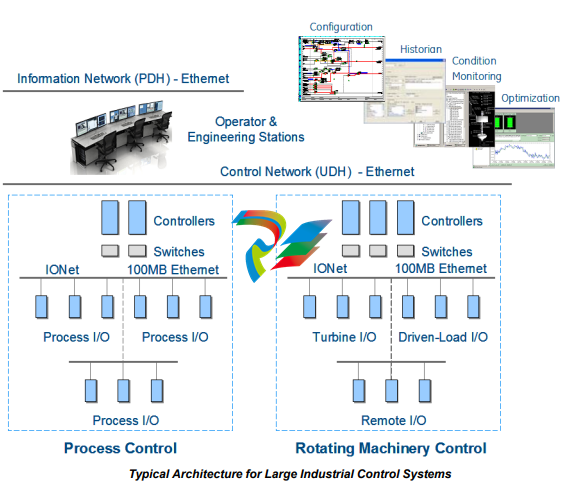

Control System Overview

Introduction

The Mark* VIe control system is a flexible platform used in multiple applications. Its architecture enables unique engineered solutions for a variety of large industrial applications. It features high-speed, networked input/output (I/O) for Simplex, Dual, and Triple Modular Redundant (TMR) systems. Industry-standard Ethernet communications are used for I/O, controllers, and supervisory interface to operator and maintenance stations, as well as third-party systems. The Mark VIeS Safety controller and I/O can operate independently or integrated with the rest of the Mark VIe controllers for safety-critical applications that conform to IEC® 61508. The ControlST* Software Suite, which contains the ToolboxST* application software, is used or programming, configuration, trending, and analyzing diagnostics for Mark controls and related systems. It provides quality, time-coherent data at controller and plant level for effectively managing control system equipment. ControlST simplifies maintenance while retaining a unique set of certified hardware and software blocks. ToolboxST provides a means to lock or unlock the Mark VIeS Safety controller for configuration and Safety Instrumented Function (SIF) programming The Universal I/O (UIO) control cabinet provides a platform for an independent, miniature version of the Mark VIe or Mark VIeS Safety control. The PUAA module is the standard Mark VIe compatible module, while the YUAA module is the companion module that is used in the Mark VIeS Safety control system. The UIO control cabinet is a lower cost, smaller footprint alternative to the standard Mark control cabinet. The control cabinet is installed at sites when there are I/O, power, and/or space limitations in the existing Mark VI, Mark VIe, or Mark VIeS control cabinet. This is especially required for upgrades when there are space restrictions. This unit may also be used as an independent Mark VIe or Mark VIeS control system, communicating directly with the Unit Data Highway (UDH) or Plant Data Highway (PDH), regardless of the existing controller at the site. The UIO control system supports specific I/O. For a list of supported I/O, refer to the Mark VIe and Mark VIeS Control Systems Volume II: System Guide for General-purpose Applications (GEH-6721_Vol_II). ToolboxST is used to set up, configure, and download to the UIO Mark VIe controller.

The information in this document applies to the overall Mark* VIe control system or Mark VIeS Functional Safety System control products; however, your application may not be licensed to access full system capability and I/O packs as described in this document. For example, the Mark VIeS Functional Safety System for General Markets only utilizes the following I/O packs:

• Analog I/O (YAIC)

• Universal Analog (YUAA)

• Vibration Input Monitor (YVIB)

• Relay Output (YDOA)

• Discrete Contact Input (YDIA)

• Power Distribution System Diagnostics (PPDA)

• Serial Modbus Communication (PSCA)

• Mark VIeS Safety Controller (UCSCS2x)

• Mark VIe Controller for Gateway (UCSCH1x)

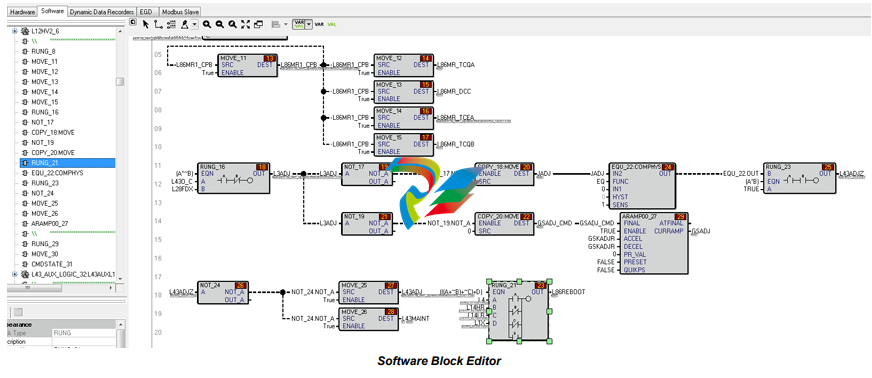

The Mark VIe and Mark VIeS control systems are used in a wide range of process control and protection applications, including steam, gas, and wind turbines, power generation balance of plant (BoP), deep sea drilling, desalinization, gas compression, and other facility-wide equipment management systems. The control system primarily consists of three hardware components: controller(s), I/O network (IONet) switches, and I/O modules. The control system provides more options for redundancy, better maintainability, and greater capability for locating I/O modules closer to the controlled equipment. It provides quality, time-coherent data at controller and plant level for effectively managing control system equipment. ControlST, which include the ToolboxST and WorkstationST applications, is used for programming, configuration, trending, and troubleshooting the Mark control product line. The following are two commonly used ToolboxST configuration screens.

Controllers

The Mark VIe controller is a stand-alone, single-board controller with scalable processing power. It includes built-in power supplies and requires no batteries or jumper settings. Controllers run the ControlST* Software Suite, providing a common software environment for turbine and generator excitation controls in the power island and balance of plant equipment to simplify operations and maintenance. The Mark VIeS Safety controller is IEC 61508 certified to SIL 3.

Controllers are loaded with software specific to its application, such as steam, gas, land-marine (LM), Balance of Plant (BoP), offshore drilling, desalination, CS, and Wind Power Conversion. It can run Relay Ladder Diagrams (RLD) or blocks. The IEEE® 1588 protocol is used through the R, S, and T I/O networks (IONet) to synchronize the clock of the I/O modules and controllers to within ±100 microseconds. Data is transferred to and from the control system database in the controller over the I/O networks (IONet). IONet data includes process inputs/outputs to the I/O packs.

In a dual system, IONet data also includes:

• Internal state values and initialization information from the designated controller • Status and synchronization information from both controllers In a triple module redundant (TMR) system, IONet data also includes: • Internal state values for voting and status and synchronization information from all three controllers • Initialization information from the designated controller

Note For more information on the Mark VIe controller, refer to the Mark VIe and Mark VIeS Control Systems Volume II: System Guide for General-purpose Applications (GEH-6721_Vol_II), the chapter Controllers. More more information on the Mark VIeS Safety controller, refer to the Mark VIeS Control Functional Safety Manual (GEH-6723). For a list of controllers that are available for each control system, including the supported and unsupported features the controllers offer for that control system, refer to the ToolboxST User Guide for Mark Controls Platform (GEH-6700 or GEH-6703).

IONet Switches

GE’s Industrial Ethernet 10/100 switches (ESWA and ESWB) provide the performance and features needed in today’s real-time industrial control systems. Use 8-port ESWA or 16-port ESWB Ethernet switches in all control system I/O networks to maintain the reliability needed for I/O module reception of controller outputs.

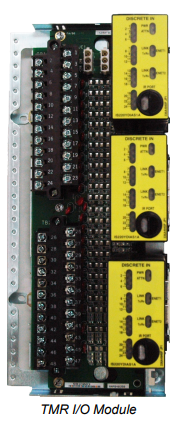

1.4 Distributed I/O Modules

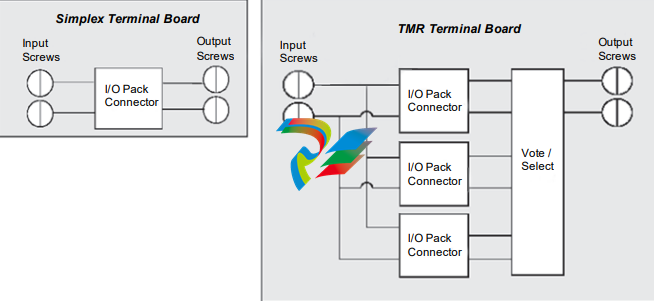

The I/O modules contain three basic parts: terminal board, terminal block, and I/O pack. The terminal board mounts to the cabinet and comes in two basic types: S and T. The I/O pack mounts to the terminal board J-port connector. Both terminal board types provide the following features:

• Terminal blocks for I/O wiring

• Mounting hardware

• Input isolation and protection

• I/O pack connectors

• Unique electronic ID

I/O packs have a common processor board and a data acquisition board that is unique to the type of connected device. I/O packs on each terminal board digitize the I/O variables, perform algorithms, and communicate with the controller. The I/O pack provides fault detection through a combination of special circuitry in the data acquisition board and software running in the Central Processing Unit (CPU) board. The fault status is transmitted to and used by the controllers. The I/O pack transmits inputs and receives outputs on both network interfaces if connected.

Each I/O pack also sends an identification message (ID packet) to the main controller when requested. The packet contains, the hardware catalog number of the I/O board, the hardware revision, the board barcode serial number, the firmware catalog number, and the firmware version. The I/O packs have a temperature sensor that is accurate to within ±2 °C (±3.6 °F). Every I/O pack temperature is available in the database and can be used to generate an alarm.

Terminal Boards

Signal flow begins with a sensor connected to a terminal block on a board. Wide and narrow terminal boards are arranged in vertical columns of high and low-level wiring. An example of a wide board is a board that contains magnetic relays with fused circuits for solenoid drivers. A shield strip is provided to the left of each terminal block. It can be connected to a metal base for immediate grounding or floated to allow individual ground wires from each board to be wired to a centralized, cabinet ground strip.

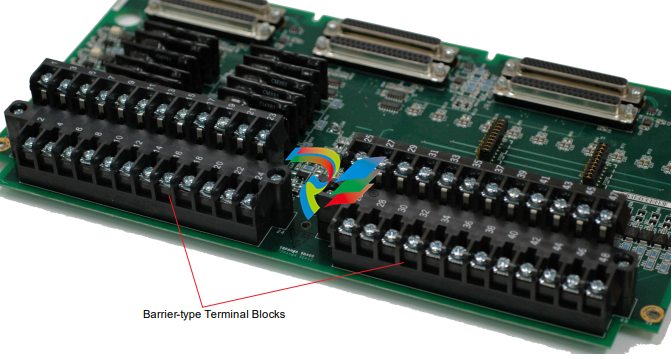

T-type

T-type terminal boards typically fan the sensor inputs to three separate I/O packs. Usually, the TMR board hardware votes the outputs from the three I/O packs. T-type boards contain two, 24-point, barrier-type, removable, terminal blocks. Each point can accept two 3.0 mm (0.12 in) (#12 AWG) wires with 300 V insulation per point with either spade or ring-type lugs. In addition, captive clamps are provided for terminating bare wires. Screw spacing is 9.53 mm (0.375 in) minimum and center-to-center

These terminal blocks have the following features:

• Black in color with white number labels

• Terminal rating is 300 V, 10 A

• UL recognized

• Recommended screw tightening torque is 7 lb-in (0.8 Nm)

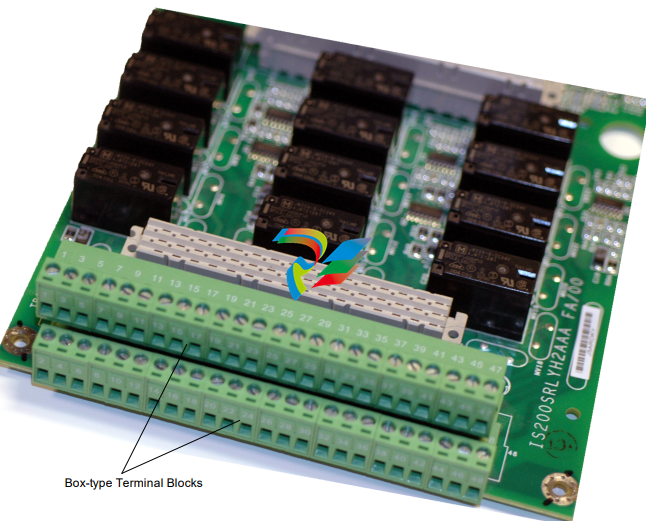

S-type

S-type boards provide a single set of screws for each I/O point and allow a single I/O pack to condition and digitize the I/O. They are half the size of T-type boards and are standard base mounted but can also be DIN-rail mounted. These boards can be used for simplex, dual, or dedicated triple redundant sensors by using one, two, or three modules. S-type boards have Euro-style, box type terminal blocks. Some boards are available as either removable or fixed terminal block versions. S-type board terminal blocks accept one 2.05 mm (0.08 in) (#12 AWG) wire or two 1.63 mm (0.06 in) (#14 AWG) wires, each with 300 V insulation per point. Screw spacing is 5.08 mm (0.2 in) minimum and center-to-center.

These terminal blocks have the following features:

• Green in color with number labels.

• Terminal rating is 300 V, 10 A

• UL and CSA recognized

• Recommended screw tightening torque is 5 lb-in (0.5 - 0.6 Nm

.png)

.png)

.png)