ABBMark* VIe and Mark VIeS Control Systems Volume I: System Guide

Safety Symbol Legend

Control System Warnings

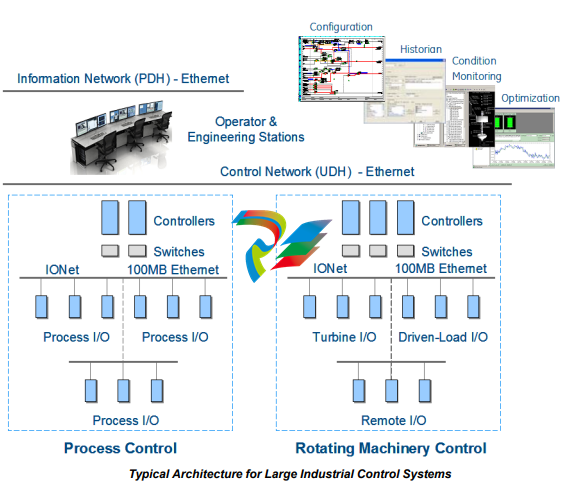

Control System Overview

Introduction

The Mark* VIe control system is a flexible platform used in multiple applications. Its architecture enables unique engineered solutions for a variety of large industrial applications. It features high-speed, networked input/output (I/O) for Simplex, Dual, and Triple Modular Redundant (TMR) systems. Industry-standard Ethernet communications are used for I/O, controllers, and supervisory interface to operator and maintenance stations, as well as third-party systems. The Mark VIeS Safety controller and I/O can operate independently or integrated with the rest of the Mark VIe controllers for safety-critical applications that conform to IEC® 61508. The ControlST* Software Suite, which contains the ToolboxST* application software, is used or programming, configuration, trending, and analyzing diagnostics for Mark controls and related systems. It provides quality, time-coherent data at controller and plant level for effectively managing control system equipment. ControlST simplifies maintenance while retaining a unique set of certified hardware and software blocks. ToolboxST provides a means to lock or unlock the Mark VIeS Safety controller for configuration and Safety Instrumented Function (SIF) programming The Universal I/O (UIO) control cabinet provides a platform for an independent, miniature version of the Mark VIe or Mark VIeS Safety control. The PUAA module is the standard Mark VIe compatible module, while the YUAA module is the companion module that is used in the Mark VIeS Safety control system. The UIO control cabinet is a lower cost, smaller footprint alternative to the standard Mark control cabinet. The control cabinet is installed at sites when there are I/O, power, and/or space limitations in the existing Mark VI, Mark VIe, or Mark VIeS control cabinet. This is especially required for upgrades when there are space restrictions. This unit may also be used as an independent Mark VIe or Mark VIeS control system, communicating directly with the Unit Data Highway (UDH) or Plant Data Highway (PDH), regardless of the existing controller at the site. The UIO control system supports specific I/O. For a list of supported I/O, refer to the Mark VIe and Mark VIeS Control Systems Volume II: System Guide for General-purpose Applications (GEH-6721_Vol_II). ToolboxST is used to set up, configure, and download to the UIO Mark VIe controller.

The information in this document applies to the overall Mark* VIe control system or Mark VIeS Functional Safety System control products; however, your application may not be licensed to access full system capability and I/O packs as described in this document. For example, the Mark VIeS Functional Safety System for General Markets only utilizes the following I/O packs:

• Analog I/O (YAIC)

• Universal Analog (YUAA)

• Vibration Input Monitor (YVIB)

• Relay Output (YDOA)

• Discrete Contact Input (YDIA)

• Power Distribution System Diagnostics (PPDA)

• Serial Modbus Communication (PSCA)

• Mark VIeS Safety Controller (UCSCS2x)

• Mark VIe Controller for Gateway (UCSCH1x)

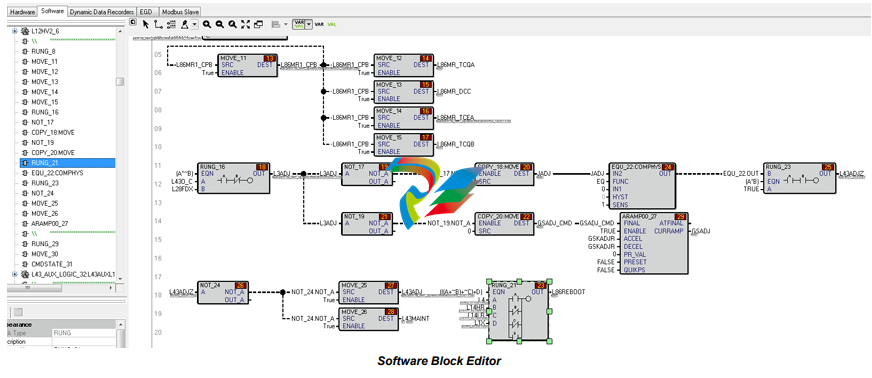

The Mark VIe and Mark VIeS control systems are used in a wide range of process control and protection applications, including steam, gas, and wind turbines, power generation balance of plant (BoP), deep sea drilling, desalinization, gas compression, and other facility-wide equipment management systems. The control system primarily consists of three hardware components: controller(s), I/O network (IONet) switches, and I/O modules. The control system provides more options for redundancy, better maintainability, and greater capability for locating I/O modules closer to the controlled equipment. It provides quality, time-coherent data at controller and plant level for effectively managing control system equipment. ControlST, which include the ToolboxST and WorkstationST applications, is used for programming, configuration, trending, and troubleshooting the Mark control product line. The following are two commonly used ToolboxST configuration screens.

Controllers

The Mark VIe controller is a stand-alone, single-board controller with scalable processing power. It includes built-in power supplies and requires no batteries or jumper settings. Controllers run the ControlST* Software Suite, providing a common software environment for turbine and generator excitation controls in the power island and balance of plant equipment to simplify operations and maintenance. The Mark VIeS Safety controller is IEC 61508 certified to SIL 3.

Controllers are loaded with software specific to its application, such as steam, gas, land-marine (LM), Balance of Plant (BoP), offshore drilling, desalination, CS, and Wind Power Conversion. It can run Relay Ladder Diagrams (RLD) or blocks. The IEEE® 1588 protocol is used through the R, S, and T I/O networks (IONet) to synchronize the clock of the I/O modules and controllers to within ±100 microseconds. Data is transferred to and from the control system database in the controller over the I/O networks (IONet). IONet data includes process inputs/outputs to the I/O packs.

.png)

.png)

.png)