A-BPOINT I/O EtherNet/IP Adapter Catalog Number 1734-AENTInstallation Instructions

mportant User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of these

products must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations,

codes and standards. In no event will Rockwell Automation be

responsible or liable for indirect or consequential damage resulting

from the use or application of these products.

Any illustrations, charts, sample programs, and layout examples

shown in this publication are intended solely for purposes of

example. Since there are many variables and requirements associated

with any particular installation, Rockwell Automation does not

assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this

publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Rockwell Automation office), describes

some important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or part, without written permission of Rockwell Automation, is

prohibited.

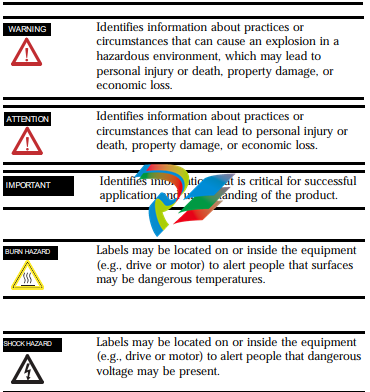

Throughout this publication, notes may be used to make you aware

of safety considerations. The following annotations and their

accompanying statements help you to identify a potential hazard,

avoid a potential hazard, and recognize the consequences of a

potential hazard

Environment and Enclosure

This equipment is intended for use in a Pollution

Degree 2 industrial environment, in overvoltage

Category II applications (as defined in IEC

publication 60664-1), at altitudes up to 2000 meters

without derating.

This equipment is considered Group 1, Class A

industrial equipment according to IEC/CISPR

Publication 11. Without appropriate precautions,

there may be potential difficulties ensuring

electromagnetic compatibility in other environments

due to conducted as well as radiated disturbance.

This equipment is supplied as "open type"

equipment. It must be mounted within an enclosure

that is suitably designed for those specific

environmental conditions that will be present and

appropriately designed to prevent personal injury

resulting from accessibility to live parts. The interior

of the enclosure must be accessible only by the use

of a tool. Subsequent sections of this publication

may contain additional information regarding

specific enclosure type ratings that are required to

comply with certain product safety certifications.

See NEMA Standards publication 250 and IEC

publication 60529, as applicable, for explanations of

the degrees of protection provided by different

types of enclosure. Also, see the appropriate

sections in this publication, as well as the

Allen-Bradley publication 1770-4.1 ("Industrial

Automation Wiring and Grounding Guidelines"), for

additional installation requirements pertaining to

this equipmen

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic

discharge, which can cause internal damage and

affect normal operation. Follow these guidelines

when you handle this equipment:

• Touch a grounded object to discharge

potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on

component boards.

• Do not touch circuit components inside the

equipment.

• If available, use a static-safe workstation.

• When not in use, store the equipment in

appropriate static-safe packaging.

ATTENTION POINT I/O is grounded through the DIN rail to

chassis ground. Use zinc-plated, yellow-chromated

steel DIN rail to assure proper grounding. Using

other DIN rail materials (e.g., aluminum, plastic,

etc.) which can corrode, oxidize or are poor

conductors, can result in improper or intermittent

platform grounding.

WARNING When you connect or disconnect the Removable

Terminal Block (RTB) with field side power

applied, an electrical arc can occur. This could

cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is

nonhazardous before proceeding

Before You Begin

To effectively use your adapter, note the following considerations.

Determine Compatibility

If using the 1734-AENT adapter with a 1756-ENBT module or

1788-ENBT module, use the following required firmware versions for

these bridge modules:

• 1756-ENBT firmware version 2.3 or greater

• 1788-ENBT firmware version 1.33 or greater

If you use the BootP Utility to assign IP addresses to the adapter, use

version 2.3.2 or greater.

Understand Messaging

Class 3 (Explicit Message) requests through the 1734-AENT adapter to

a specific POINT I/O module may not always receive a response

from the I/O modules. In the case where the I/O module does not

reply to the request, the adapter responds with an error code

indicating a time-out.

Establish I/O Connections

When you power up a POINT I/O system and establish I/O

connections, the outputs transition to the Idle state, applying Idle

state data before going to RUN mode. This occurs even when the

controller making the connection is already in RUN mode.

Configure Autobaud

The adapter cannot reconfigure an I/O module that you previously

configured to operate at a fixed baud rate. When you reuse a POINT

I/O module from another POINT I/O system, configure the module

to autobaud before using it with the adapter.

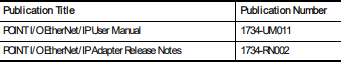

For More Information

The following related publications are available online at URL

http://literature.rockwellautomation.com.

Install the EtherNet/IP Adapter

To install the adapter on the DIN rail prior to installing other base

units, proceed as follows.

1. Position the adapter vertically above the DIN rail.

2. Press down firmly to install the adapter on the DIN rail. The

locking mechanism will lock the adapter to the DIN rail.

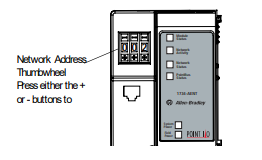

3. Set the node address on the node address thumbwheel.

If you connect or disconnect the Ethernet cable with power applied to this module or any device on the network, an electrical arc can occur. This could cause an explosion in hazardous location installations. Be sure that power is removed or the area is nonhazardous before proceeding.

POINT I/O EtherNet/IP AdapterSlide the safety end cap up to remove. This exposes the backplane and power interconnections.

Do not discard the end cap. Use this end cap to

cover the exposed interconnections on the last

mounting base on the DIN rail. Failure to do so

could result in equipment damage or injury from

electric shock

Set the Network Address

The adapter ships with the thumbwheel switches set to 999 and

DHCP enabled. You can set the network Internet Protocol (IP)

address 3 ways:

• Use the thumbwheel switches on the module

• Use a Dynamic Host Configuration Protocol (DHCP) server,

such as Rockwell Automation BootP/DHCP

• Retrieve the IP address from nonvolatile memory

The adapter reads the thumbwheel switches first to determine if the switches are set to a valid number. You set the node address using the 3-position thumbwheel switch. Press the + or - buttons to change the number. Valid settings range from 001 to 254. When the switches are set to a valid number, the adapter’s IP address is 192.168.1.xxx (where xxx represents the number set on the switches). The adapter’s

subnet mask is 255.255.255.0 and the gateway address is set to

0.0.0.0. The adapter does not have a host name assigned, or use any

Domain Name System when using the thumbwheel settings.

If you set the switches to an invalid number (i.e. 000 or a value

greater than 254), the adapter checks to see if you enabled DHCP,

according to the following table.

Refer to publication 1734-UM011, POINT I/O EtherNet/IP Adapter

User Manual, for more information.

Install a Replacement EtherNet/IP Adapter to an Existing System

1. Remove the existing adapter from the DIN rail as follows:

a. Disconnect the EtherNet connector from the adapter.

b. Pull up on the RTB removal handle to remove the terminal

block.

c. Remove the adjacent module from its base.

d. Use a small bladed screwdriver to rotate the DIN rail

locking screw to a vertical position. This releases the

locking mechanism.

e. Lift straight up to remove.

If DHCP is Then the adapter

Enabled Asks for an address from a DHCP server. The

DHCP server also assigns other Transport

Control Protocol (TCP) parameters.

Not enabled Uses the IP address (along with other TCP

configurable parameters) stored in nonvolatile

memory

ATTENTION You must use Series C POINT I/O modules with the

1734-AENT adapter. Series A or B POINT I/O

modules do not work with this adapter.

2. Slide the safety end cap up to remove. This exposes the

backplane and power connections.

3. Position the replacement adapter vertically above the DIN rail.

Make certain the DIN rail lock is in the horizontal position.

Slide the adapter down, allowing the interlocking side pieces

to engage the adjacent module.

4. Press firmly to seat the adapter on the DIN rail. The adapter

locking mechanism will snap into place.

5. Set the node address on the node address thumbwheel.

6. Insert the end of the terminal block (RTB) opposite the handle

into the base unit. This end has a curved section that engages

with the wiring base.

7. Rotate the terminal block into the wiring base until it locks

itself into place.

8. Replace the adjacent module in its base.

9. Reconnect the Ethernet cable to the adapter.

10. Set the IP Address for this module. Refer to the Setting the

Network Address section of these instructions.

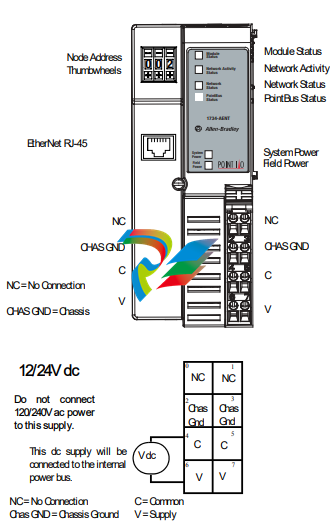

Wire the EtherNet/IP Adapter

WARNING If you connect or disconnect wiring while the

field-side power is on, an electrical arc can occur.

this could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is

nonhazardous before proceeding.

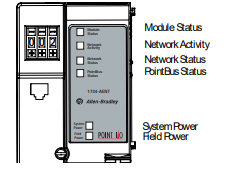

Troubleshoot with the Indicators

Indication Probable Cause

System Power

Off Not active; field power is off or dc-dc converter problem

Green System power on; dc-dc converter active (5V)

Field Power

Off Not active; field power is off

Green Power on; 24V present

Module Status

Off No power applied to device

Flashing Red/Green LED powerup test (module self-test)

Green Device is operating normally

Flashing Red Recoverable fault has occurred:

• Firmware (NVS) update

• Network IP Address changed

• CPU load exceeded

Solid Red Unrecoverable fault has occurred:

• Self-test failure (checksum failure, or ramtest failure at

powerup)

• Firmware fatal error

ndication Probable Cause

Network Status

Off Device not initialized. The module does not have an IP address.

Flashing Green No CIP connections. Device has an IP address, but no CIP

connections are established.

Green CIP connections. Device on-line and has an IP address, and CIP

connections are established.

Flashing Red One or more EtherNet connections has timed-out.

Red No link. The module is not physically connected to a powered

EtherNet Device.

Flashing Red/Green The module is performing a self-test (only occurs during

powerup test).

Network Activity

Off No link established.

Flashing Green/Off Transmit or receive activity.

Steady Green Link established.

PointBus Status

Off Device not powered - check module status indicator.

Flashing Red/Green LED powerup test.

Flashing Red Recoverable fault has occurred:

• at powerup the number of expected modules

does not equal the number of modules present

• a module is missing

• node fault (I/O connection timeout)

POINT I/O EtherNet/IP Adapter

Publication 1734-IN590B-EN-P - February 2016

European Hazardous Location Approval

Red Unrecoverable fault has occurred:

• the adapter is bus off

• the adapter has failed its duplicate MAC ID check

Flashing Green Adapter online with no connections established:

• adapter chassis size has not been configured

• controller in program/idle mode

• EtherNet cable open

Green Adapter online with connections established (normal

operation, run mode).

European Zone 2 Certification (The following applies when the product bears the

EEx Marking)

This equipment is intended for use in potentially explosive atmospheres as defined by

European Union Directive 94/9/EC.

DEMKO certifies that this equipment has been found to comply with the Essential Health

and Safety Requirements relating to the design and construction of Category 3 equipment

intended for use in potentially explosive atmospheres, given in Annex II to this Directive.

The examination and test results are recorded in confidential report No 03NK30347.

Compliance with the Essential Health and Safety Requirements has been assured by

compliance with EN 50021.

IMPORTANT Observe the following additional Zone 2 certification requirements.

• This equipment is not resistant to sunlight or other sources of

UV radiation.

• The secondary of a current transformer shall not be

open-circuited when applied in Class I, Zone 2 environments.

• Equipment of lesser Enclosure Type Rating must be installed in

an enclosure providing at least IP54 protection when applied

in Class I, Zone 2 environments.

• This equipment shall be used within its specified ratings

defined by Allen-Bradley.

• Provision shall be made to prevent the rated voltage from

being exceeded by transient disturbances of more than 40%

when applied in Class I, Zone 2 environments

North American Hazardous Location Approval

The following information applies when

operating this equipment in hazardous

locations:

Informations sur l’utilisation de cet équipement

en environnements dangereux:

Products marked “CL I, DIV 2, GP A, B, C, D” are

suitable for use in Class I Division 2 Groups A, B,

C, D, Hazardous Locations and nonhazardous

locations only. Each product is supplied with

markings on the rating nameplate indicating the

hazardous location temperature code. When

combining products within a system, the most

adverse temperature code (lowest “T” number)

may be used to help determine the overall

temperature code of the system. Combinations of

equipment in your system are subject to

investigation by the local Authority Having

Jurisdiction at the time of installation.

Les produits marqués “CL I, DIV 2, GP A, B, C, D” ne

conviennent qu’à une utilisation en environnements

de Classe I Division 2 Groupes A, B, C, D dangereux et

non dangereux. Chaque produit est livré avec des

marquages sur sa plaque d’identification qui

indiquent le code de température pour les

environnements dangereux. Lorsque plusieurs

produits sont combinés dans un système, le code de

température le plus défavorable (code de température

le plus faible) peut être utilisé pour déterminer le

code de température global du système. Les

combinaisons d’équipements dans le système sont

sujettes à inspection par les autorités locales

qualifiées au moment de l’installation.

EXPLOSION HAZARD -

• Do not disconnect equipment unless

power has been removed or the area

is known to be nonhazardous.

• Do not disconnect connections to

this equipment unless power has

been removed or the area is known

to be nonhazardous. Secure any

external connections that mate to

this equipment by using screws,

sliding latches, threaded

connectors, or other means provided

with this product.

• Substitution of components may

impair suitability for Class I, Division

2.

• If this product contains batteries,

they must only be changed in an

area known to be nonhazardous.

RISQUE D’EXPLOSION –

• Couper le courant ou s’assurer que

l’environnement est classé non

dangereux avant de débrancher

l'équipement.

• Couper le courant ou s'assurer que

l’environnement est classé non

dangereux avant de débrancher les

connecteurs. Fixer tous les connecteurs

externes reliés à cet équipement à

l'aide de vis, loquets coulissants,

connecteurs filetés ou autres moyens

fournis avec ce produit.

• La substitution de composants peut

rendre cet équipement inadapté à une

utilisation en environnement de Classe

1, Division 2.

• S’assurer que l’environnement est

classé non dangereux avant de changer

les piles.

Specifications

Adapter Specifications

Expansion I/O Capacity Maximum of 63 modules

Maximum of 5 Rack Optimized connections (for digital modules

only)

Maximum of 20 direct connections

1734-AENT backplane current output = 1.0A.

The actual number of modules can vary. Add up the current

requirements of the modules you want to use to make sure they do

not exceed the amperage limit of 1.0A for the 1734-AENT.

Backplane current can be extended beyond 1.0A by using

1734-EP24DC backplane extension Power Supplies. Add multiple

1734-EP24DC modules to reach the 63 module maximum).

Cat. No. PointBus Current Requirements

1734-IB2 75mA

1734-IB4 75mA

1734-IB8 75mA

1734-IV2 75mA

1734-IV4 75mA

1734-OB2 75mA

1734-OB4 75mA

1734-OB8 75mA

1734-OB2E 75mA

1734-OB2EP 75mA

1734-OB4E 75mA

1734-OB8E 75mA

1734-OV2E 75mA

1734-OV4E 75mA

1734-OW2 80mA

1734-OX2 100mA

1734-IE2C 75mA

1734-OE2C 75mA

1734-IE2V 75mA

1734-OE2V 75mA

1734-IA2 75mA

1734-IM2 75mA

1734-OA2 75mA

1734-IJ2 160mA

1734-IK2 160mA

1734-IR2 220mA

1734-IT2I 175mA

1734-SSI 110mA

1734-VHSC5 180mA

1734-VHSC24 180mA

1734-232ASC 75mA

1734-485ASC 75mA

EtherNet

Communication Rate

10/100Mbits/s, half or full-duplex

Module Location Starter module - left side of the 1734 system

Power Supply Specifications

Input Voltage Rating 24V dc nominal

10-28.8V dc range

Field Side Power

Requirements

24V dc (+20% = 28.8V dc maximum) @ 400mA maximum

Inrush Current 6A maximum for 10ms

Interruption Output voltage will stay within specifications when input drops out

for 10ms at 10V with maximum load.

General Specifications

Indicators 4 red/green status indicators

Adapter status

PointBus status

Network activity status

Network status

2 green power supply status indicators:

System Power (PointBus 5V power)

Field Power (24V from field supply)

Power Consumption 4.5W maximum @ 28.8V dc

Power Dissipation 15.5W maximum @ 28.8V

PointBus Output

Current

1A maximum @ 5V dc ±5% (4.75 - 5.25)

Input Overvoltage

Protection

Reverse polarity protected

Thermal Dissipation 9.5 BTU/hr maximum @ 28.8V dc

Isolation Voltage Tested to withstand 1800V dc for 60s

Field Power Bus

Nominal Voltage

Supply Voltage Range

Supply Current

24V dc

10-28.8V dc range

10A maximum

Dimensions Inches

(Millimeters)

3.0H x 2.16W x 5.25L

(76.2H x 54.9W x 133.4L)

Environmental

Conditions

Operational

Temperature

IEC 60068-2-1 (Test Ad, Operating Cold),

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20 to 55° C (-4 to 131° F)

Storage

Temperature

IEC 60068-2-1 (Test Ab, Unpackaged Nonoperating Cold),

IEC 60068-2-2 (Test Bb, Unpackaged Nonoperating Dry Heat),

IEC 60068-2-14 (Test Na, Unpackaged Nonoperating Thermal

Shock): -40 to 85° C (-40 to 185° F)

Relative Humidity IEC 60068-2-30 (Test Db, Unpackaged Nonoperating Damp Heat): 5

to 95% noncondensing

Shock IEC 60068-2-27 (Test Ea, Unpackaged Shock)

Operating 30g peak acceleration

Nonoperating 50g peak acceleration

Vibration IEC 60068-2-6 (Test Fc, Operating)

Tested 5g @ 10-500Hz

ESD Immunity IEC 61000-4-2:

6kV contact discharges

8kV air discharges

Radiated RF

Immunity

IEC 61000-4-3:

10V/m with 1kHz sine-wave 80%AM from 30MHz to 2000MHz

10V/m with 200Hz 50% pulse 100%AM from 900MHz

EFT/B Immunity IEC 61000-4-4:

+4kV at 5.0kHz on power ports

+2kV at 5.0kHz on communications ports

Surge Transient

Immunity

IEC 61000-4-5:

+1kV line-line(DM) and +2kV line-earth(CM) on communications

ports

+1kV line-line(DM) and +2kV line-earth(CM) on power ports

Conducted RF

Immunity

IEC 61000-4-6:

10Vrms with 1kHz sine-wave 80%AM from 150kHz to 80MHz

Emissions CISPR 11

Group 1, Class A

Enclosure Type Rating None (open-style)

Conductors

Wire Size

Wiring Category1,2

14-22 AWG (2.5-0.25mm2

) solid or stranded wire

rated at 75o

C or higher

3/64 inch (1.2mm) insulation maximum

1 - on power ports

2 - on communications ports

EtherNet Connector RJ-45, Category 5

Terminal Base Screw

Torque

7 pound-inches (0.8Nm)

Mass 9.0 oz/255 grams

Certifications3

(when product is

marked)

C-UL-USUL Listed for Class I, Division 2, Groups A, B, C and D

Hazardous locations, certified for US and Canada

EEX European Union 94/9/EC ATEX Directive,

compliant with:

EN 50021; Potentially Explosive Atmospheres,

Protection “n” (Zone 2)

CE European Union 89/336/EEC EMC Directive,

compliant with:

EN 61000-6-4; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab., Industrial

Requirements

EN 61000-6-2; Industrial Immunity

C-Tick Australian Radiocommunications Act, compliant with:

AS/NZS CISPR 11; Industrial Emissions

EtherNet/IP

ODVA conformance tested to EtherNet/IP specifications

1 Use this conductor category information for planning conductor routing as described in publication

1770-4.1, “Industrial Automation Wiring and Grounding Guidelines.”

2 Use the Conductor Category information for planning conductor routing as described in the

appropriate System Level Installation Manual.

3 See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and

other certification details.

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you

in using its products. At http://support.rockwellautomation.com, you can find

technical manuals, a knowledge base of FAQs, technical and application

notes, sample code and links to software service packs, and a MySupport

feature that you can customize to make the best use of these tools.

For an additional level of technical phone support for installation,

configuration and troubleshooting, we offer TechConnect Support programs.

For more information, contact your local distributor or Rockwell Automation

representative, or visit http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours

of installation, please review the information that's contained in this manual.

You can also contact a special Customer Support number for initial help in

getting your module up and running:

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when

shipped from the manufacturing facility. However, if your product is not

functioning and needs to be returned:

United States 1.440.646.3223 Monday – Friday, 8am – 5pm EST

Outside United States Please contact your local Rockwell Automation representative for any

technical support issues.

United States Contact your distributor. You must provide a Customer Support case number

(see phone number above to obtain one) to your distributor in order to

complete the return process.

Outside United States Please contact your local Rockwell Automation representative for return

procedure.

.png)

.png)

.png)