DOOSANDOOSAN AC SERVO MOTOR/DRIVE VISION DVSC - TM Series

To prevent the effect of the switching noise, the motor frame terminal should be connected to

the PE terminal of the servo drive terminal block and the PE terminal of the servo drive should be

directly grounded to standard ground panel.

▶ Noise filter

Noise filter is used in order to prevent noise from the power line. Please refer to the following

conditions while installing.

(a) Separate the input and output wiring and do not tie them together or put them into the same

duct.

(b) Do not put the ground wire into the same duct with the filter output line or other signal lines.

And do not tie them together.

(c) The ground wire should be wired singly to the ground panel.

(d) If the unit contains the filter, connect the filter and the equipment ground to the base of the

unit.

2. Operation

2.1. Automatic operation

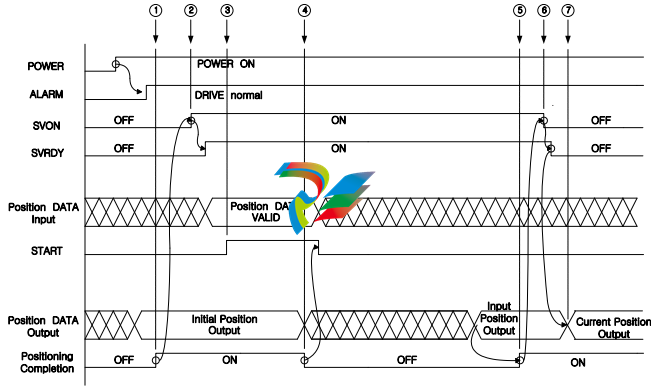

① If the drive maintains a normal state (takes 5 sec) after the POWER turns on, it outputs the initial

position data and the positioning completion signal(VPF) after it detects the initial position by the

absolute encoder.

② When the SVON signal is ON, the SVRDY signal turns ON after the inner GATE turns ON.

③ When the START signal is ON, the servo motor will rotate according to the position data.

(Maintain ON state of the START signal for about 100 ~ 200 msec.)

④ When the position movement starts, the position data 0 will be outputted with turning OFF the

VPF(Positioning Completion) signal.

⑤ When the position movement is complete, the VPF signal turns ON after the position input data is

outputted.

⑥ The host controller must turn OFF the SVON signal only after the VPF signal turns ON.

(Move to the next position after the SVRDY signal turns OFF.)

⑦ After the SVRDY and the SVON signals are turned OFF, the current position data is outputted.

2.2. Jog operation and Usage of BRAKE Signal(Magazine Port move by the jog signal)

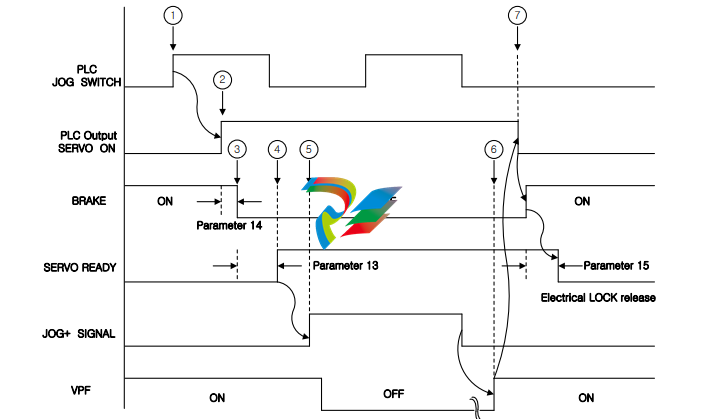

① Turn ON the Jog Switch.

② The PLC outputs the SERVO ON signal to the servo drive.

③ When the SERVO ON signal turns ON, the BRAKE release signal is outputted after the time value in

the parameter 14.

④ After the time value in the parameter 13, the SERVO READY signal is outputted.

⑤ After the SERVO READY signal is outputted, the PLC must input the JOG+ signal to the servo drive.

⑥ When the position movement is complete, the positioning completion signal(VPF) turns ON after

the position data that is increased by more than one from the previous position is outputted.

⑦ When the positioning completion signal(VPF) turns ON, the PLC turns OFF the SERVO ON signal.

Then, the servo drive turns ON the BRAKE signal and turns OFF the SERVO READY signal after the

time value in the parameter 15.

The servo drive outputs the current position data after the SERVO ON signal turns OFF.

※ In the jog mode, the motor cannot rotate over 4,000 revolutions continuously. If there is an input

over 4,000 revolutions, the motor will stop and it will not rotate. In this case, turn off the JOG+ or

JOG- signal and then turn it on again.

2.3. Parameter and Machine Origin setting method after replacement of the servo drive

At the time of the first machine assembly, it should be set the absolute encoder zero-point to the

Machine Origin. The setting method is as follows.

(These steps should be done when the external SERVO ON signal is OFF.)

2.3.1. Parameter and Machine Origin setting method of Turret/Magazine

1) Turn on the drive power.

2) Clamp the Turret.

3) Set value of the parameter 45, servo drive function selection parameter, as 0.

Please change the parameter 45 as 1 only when it needs to set as ATC because default value is 0,

Turret/Magazine. Turn the drive power OFF and then turn ON again after setting the value.

4) Initialize the parameter value.

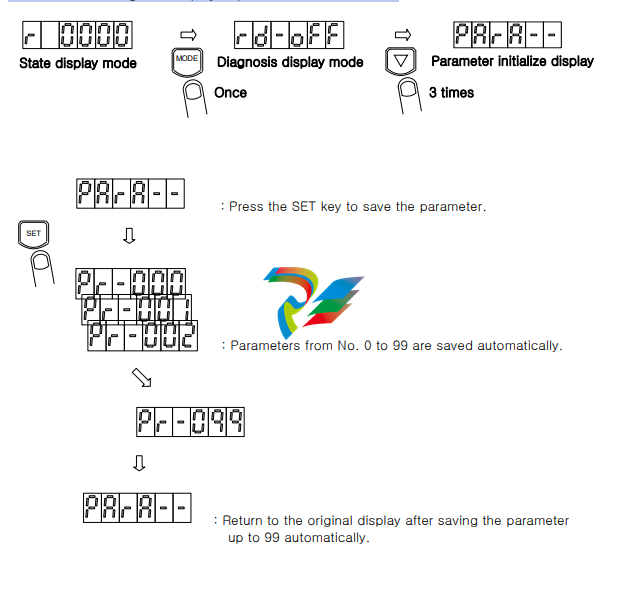

Press the MODE key to change the display to diagnosis mode, and then press the DOWN key

three times to change the display to parameter initialize mode.

Even if an alarm occurs, it’s possible to change the display as state display mode, diagnosis display

mode, parameter setting mode, origin setting mode and alarm history display mode since version

DVSC-TM-14D-02. Also, even at alarm state, parameter or offset value setting is possible since that

version.

▶ Method of releasing the alarm state

: Once the cause of the alarm is resolved, it is possible to operate the drive by turning the power

OFF and ON again.

▶ Detection time of over load

: The operation time of the over load alarm detect circuit is as listed below.

300% ~ ; 5.5sec

275% ~ ; 6.5sec

225% ~ ; 8sec

200% ~ ; 10sec

170% ~ ; 14sec

150% ~ ; 17.5sec

140% ~ ; 20sec

130% ~ ; 25sec

120% ~ ; 30sec

3.6.3. Detailed explanation of user parameter

□0 Motor output capacity

As selection parameter of the applied motor capacity, it’s possible to select 0.8, 1.5, 1.7, 2.0, 2.3,

3.0 and 4.0kW.

0 : 1.5kW 8 : 0.8kW 17 : 1.7kW 20 : 2.0kW 23 : 2.3kW 30 : 3.0kW 40 : 4.0kW

※ Use 14A drive for motors under 3.0kW and 28A drive for motors more than 3.0kW. If not applied

properly, it may cause malfunction of the motor.

□1 Motor rotation direction

This parameter sets the rotation direction of the motor. Please select according to the structure

.png)

.png)

.png)