HIMAHIMatrix Safety-Related Controller F31 03 Manual

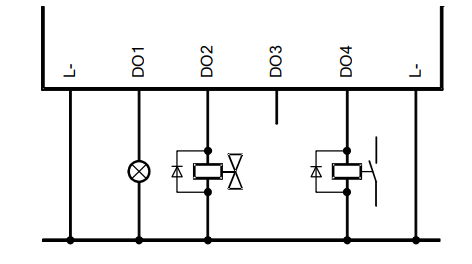

For connecting a load to a 1-pole switching output, use the corresponding L- ground of

the respective channel group (2-pole connection) to ensure that the internal protective

circuit can function.

nductive loads may be connected with no free-wheeling diode on the actuator. However, HIMA

strongly recommends connecting a protective diode directly to the actuator.

Reaction in the Event of a Fault

If the device detects a faulty signal on a digital output, the affected module output is set to the

safe (de-energized) state using the safety switches.

If a device fault occurs, all digital outputs are switched off.

In both cases, the devices activates the FAULT LED.

The error code allows the user to configure additional fault reactions in the user program.

information on how to install, start up and configure the module in SILworX.

1.1 Structure and Use of this Manual

The content of this manual is part of the hardware description of the HIMatrix programmable

electronic system.

This manual is organized in the following main chapters:

Introduction

Safety

Product Description

Start-up

Operation

Maintenance

Decommissioning

Transport

Disposal

Additionally, the following documents must be taken into account:

Name Content Document number

HIMatrix System Manual

Compact Systems

Hardware description of the HIMatrix

compact systems

HI 800 141 E

HIMatrix Safety Manual Safety functions of the HIMatrix system HI 800 023 E

HIMatrix Safety Manual for

Railway Applications

Safety functions of the HIMatrix system

using the HIMatrix in railway

applications

HI 800 437 E

SILworX Communication

Manual

Description of the communication

protocols, ComUserTask and their

configuration in SILworX

HI 801 101 E

SILworX Online Help Instructions on how to use SILworX -

SILworX First Steps Introduction to SILworX using the

HIMax system as an example

HI 801 103 E

Table 1: Additional Relevant Documents

The latest manuals can be downloaded from the HIMA website at www.hima.com. The revision

index on the footer can be used to compare the current version of existing manuals with the

Internet edition.

1.2 Target Audience

This document addresses system planners, configuration engineers, programmers of

automation devices and personnel authorized to implement, operate and maintain the modules

and systems. Specialized knowledge of safety-related automation systems is required

1.3 Formatting Conventions

To ensure improved readability and comprehensibility, the following fonts are used in this

document:

Bold To highlight important parts.

Names of buttons, menu functions and tabs that can be clicked and used

in the programming tool.

Italics For parameters and system variables

Courier Literal user inputs

RUN Operating state are designated by capitals

Chapter 1.2.3 Cross references are hyperlinks even though they are not particularly

marked. When the cursor hovers over a hyperlink, it changes its shape.

Click the hyperlink to jump to the corresponding position.

Safety notes and operating tips are particularly marked.

1.3.1 Safety Notes

The safety notes are represented as described below.

These notes must absolutely be observed to reduce the risk to a minimum. The content is

structured as follows:

Signal word: warning, caution, notice

Type and source of risk

Consequences arising from non-observance

Risk prevention

Type and source of risk!

Consequences arising from non-observance

Risk prevention

The signal words have the following meanings:

Warning indicates hazardous situation which, if not avoided, could result in death or serious

injury.

Caution indicates hazardous situation which, if not avoided, could result in minor or modest

injury.

Notice indicates a hazardous situation which, if not avoided, could result in property damage

Type and source of damage!

Damage prevention

Safety

All safety information, notes and instructions specified in this document must be strictly

observed. The product may only be used if all guidelines and safety instructions are adhered to.

This product is operated with SELV or PELV. No imminent risk results from the product itself.

The use in Ex-Zone is permitted if additional measures are taken.

2.1 Intended Use

HIMatrix components are designed for assembling safety-related controller systems.

When using the components in the HIMatrix system, comply with the following general

requirements.

Environmental Requirements

Requirement type Range of values

Protection class Protection class III in accordance with IEC/EN 61131-2

Ambient temperature 0...+60 °C

Storage temperature -40...+85 °C

Pollution Pollution degree II in accordance with IEC/EN 61131-2

Altitude < 2000 m

Housing Standard: IP20

Supply voltage 24 VDC

Table 2: Environmental Requirements

Exposing the HIMatrix system to environmental conditions other than those specified in this

manual can cause the HIMatrix system to malfunction.

2.1.2 ESD Protective Measures

Only personnel with knowledge of ESD protective measures may modify or extend the system

or replace devices.

Device damage due to electrostatic discharge!

When performing the work, make sure that the workspace is free of static, and wear

an ESD wrist strap.

If not used, ensure that the device is protected from electrostatic discharge, e.g., by

storing it in its packaging

Residual Risk

No imminent risk results from a HIMatrix system itself.

Residual risk may result from:

Faults related to engineering

Faults related to the user program

Faults related to the wiring

2.3 Safety Precautions

Observe all local safety requirements and use the protective equipment required on site.

2.4 Emergency Information

A HIMatrix system is a part of the safety equipment of a site. If a device or a module fails, the

system enters the safe state.

In case of emergency, no action that may prevent the HIMatrix systems from operating safely is

permitted.

Product Description

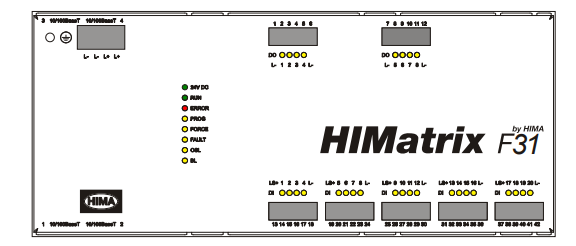

The safety-related F31 03 controller is a compact system in a metal housing with 20 digital

inputs and 8 digital outputs.

The configuration is performed using SILworX, see Chapter 4.3.

The device is suitable for sequence of events recording (SOE), see Chapter 4.2. The device

supports multitasking and reload. For more details, refer to the system manual compact

systems (HI 800 141 E).

The device is TÜV-certified for safety-related applications up to SIL 3 (IEC 61508, IEC 61511

and IEC 62061), Cat. 4 and PL e (EN ISO 13849-1) and SIL 4 (EN 50126, EN 50128 and

EN 50129).

Further safety standards, application standards and test standards are specified in the

certificates available on the HIMA website.

Safety Function

The controller is equipped with safety-related digital inputs and outputs.

3.1.1 Safety-Related Digital Inputs

The controller is equipped with 20 digital inputs. The state (HIGH, LOW) of each input is

signaled by an individual LED.

Mechanical contacts without own power supply or signal power source can be connected to the

inputs.

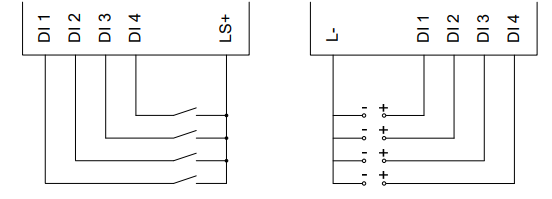

Potential-free mechanical contacts without own power supply are fed via an internal shortcircuit-proof 24 V power source (LS+). Each of them supply a group of 4 mechanical contacts.

Figure 1 shows how the connection is performed.

With signal voltage sources, the corresponding ground must be connected to the input (L-), see

Figure 1.

For the external wiring and the connection of sensors, apply the de-energized-to-trip principle.

Thus, if a fault occurs, the input signals adopt a de-energized, safe state (low level).

If an external wire is not monitored, an open-circuit is considered as safe low level.

Reaction in the Event of a Fault

If the device detects a fault on a digital input, the user program processes a low level in

accordance with the de-energized to trip principle.

The device activates the FAULT LED.

In addition to the channel signal value, the user program must also consider the corresponding

error code.

The error code allows the user to configure additional fault reactions in the user program.

Line Control

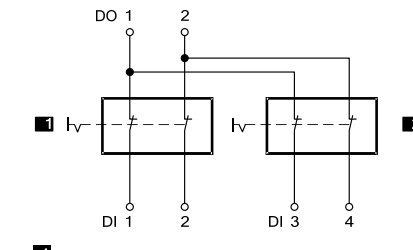

Line control is used to detect short-circuits or open-circuits and can be configured for the F31

system, e.g., on EMERGENCY STOP inputs complying with Cat. 4 and PL e in accordance with

EN ISO 13849-1.

To this end, connect the digital outputs DO 1 through DO 8 of the system to the digital inputs DI

of the same system as follows:

The controller pulses the digital outputs to detect the line short-circuits and open-circuits on the

lines connected to the digital inputs. To do so, configure the Value [BOOL] -> system variable in

SILworX. The variables for the pulsed outputs must begin with channel 1 and reside in direct

sequence, one after the other.

If the following faults occur, the FAULT LED located on the front plate of the controller blinks,

the inputs are set to low level and an (evaluable) error code is created:

Cross-circuit between two parallel wires.

Invalid connections of two lines (e.g., DO 2 to DI 3),

Earth fault on one wire (with earthed ground only).

Open-circuit or open contacts, i.e., including when one of the two EMERGENCY STOP

switches mentioned above has been engaged, the FAULT LED blinks and the error code is

created.

Safety-Related Digital Outputs

The controller is equipped with 8 digital outputs. The state (HIGH, LOW) of each output is

signaled by an individual LED (HIGH, LOW).

At the maximum ambient temperature, the outputs 1...3 and 5...7 can be loaded with 0.5 A

each; and outputs 4 and 8 can be loaded with 1 A or with 2 A at an ambient temperature of up

to 50 °C.

If an overload occurs, one or all digital outputs are switched off. If the overload is removed, the

outputs are switched on again automatically, see Table 14.

The external wire of an output is not monitored, however, a detected short-circuit is signaled.

The redundant connection of two outputs must be decoupled with diodes

Equipment, Scope of Delivery

The following table specifies the available controller:

Designation Description

F31 03

SILworX

Controller (enhanced performance, 20 digital inputs, 8 digital outputs),

Operating temperature: 0...+60 °C,

for SILworX programming tool

IP Address and System ID (SRS)

A transparent label is delivered with the device to allow one to note the IP addresses of the CPU

and the COM and the system ID (SRS for system rack slot) after a change.

Default value for IP address of the CPU: 192.168.0.99

Default value for IP address of the COM: 192.168.0.100

Default value for SRS: 60 000.0.0

The label must be affixed such that the ventilation slots in the housing are not obstructed.

Refer to the SILworX First Steps manual for more information on how to modify the IP address

and the system ID.

Type Label

The type plate contains the following details:

Product name

Bar code (1D or 2D code)

Part no.

Production year

Hardware revision index (HW Rev.)

Firmware revision index (FW Rev.)

Operating voltage

Mark of conformity

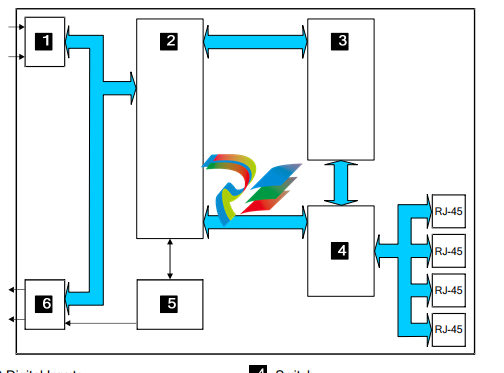

Structure

This chapter describes the layout and function of the controller, and its connection for

communication

LED Indicators

The light-emitting diodes (LEDs) indicate the operating state of the controller. The LEDs are

classified as follows:

Operating voltage LED

System LEDs

Communication LED

I/O LEDs

When the supply voltage is switched on, a LED test is performed and all LEDs are briefly lit.

Definition of Blinking Frequencies

The following table defines the blinking frequencies of the LEDs:

Name Blinking frequencies

Blinking1 Long (approx. 600 ms) on, long (approx. 600 ms) off

Blinking-x Ethernet communication: Blinking synchronously with data transfer

Communication LEDs

All RJ-45 connectors are provided with a small green and a yellow LEDs. The LEDs signal the

following states:

LED Status Description

On Full duplex operation

Blinking1 IP address conflict, all communication LEDs are blinking

Blinking-x Collision

Green

Off Half duplex operation, no collision

On Connection available

Blinking1 IP address conflict, all communication LEDs are blinking

Blinking-x Interface activity

Yellow

Off No connection available

Communication

The controller communicates with remote I/Os via safeethernet. Characteristics and

configuration of safeethernet are described in the SILworX communication manual

(HI 801 101 E).

3.4.2.1 Connections for Ethernet Communication

Property Description

Port 4 x RJ-45

Transfer standard 10BASE-T/100BASE-Tx, half and full duplex

Auto negotiation Yes

Auto crossover Yes

IP address Freely configurable1)

Subnet mask Freely configurable1)

Supported protocols Safety-related: safeethernet, PROFIsafe

Standard protocols: Programming and debugging tool (PADT),

OPC, Modbus TCP, TCP SR, SNTP, ComUserTask,

PROFINET

1) The general rules for assigning IP address and subnet masks must be adhered to.

Table 9: Ethernet Interfaces Properties

Two RJ-45 connectors with integrated LEDs are located on the top and on the bottom left-hand

side of the housing. Refer to Chapter 3.4.1.3 for a description of the LEDs' function.

The connection parameters are read based on the MAC address (media access control

address) defined during manufacturing.

CPU and COM have their own MAC addresses. The CPU MAC address is specified on a label

located above the two RJ-45 connectors (1 and 2).

Figure 7: Sample MAC Address Label

The COM MAC address corresponds to the CPU MAC address, except for the last byte which is

increased by 1.

Example:

CPU MAC address: 00:E0:A1:00:06:C0

COM MAC address: 00:E0:A1:00:06:C1

The controller is equipped with an integrated switch for Ethernet communication. For further

information on the integrated switch and safeethernet, refer to Chapter Communication of the

system manual for compact systems (HI 800 141 E).

Network Ports Used for Ethernet Communication

UDP ports Use

123 SNTP (time synchronization between PES and remote I/O, PES and

external devices)

502 Modbus salve (can be modified by the user)

6010 safeethernet and OPC

6005 / 6012 If TCS_DIRECT was not selected in the HH network

8000 Programming and operation with SILworX

8004 Configuration of the remote I/O using the PES (SILworX)

34 964 PROFINET endpoint mapper (required for establishing the connection)

49 152 PROFINET RPC server

49 153 PROFINET RPC client

Table 10: Network Ports (UDP Ports) in Use

TCP ports Use

502 Modbus salve (can be modified by the user)

xxx TCP SR assigned by the user

Table 11: Network Ports (TCP Ports) in Use

i The ComUserTask can use any port if it is not already used by another protocol.

Reset Key

The controller is equipped with a reset key. The key is only required if the user name or

password for administrator access is not known. If only the IP address set for the controller does

not match the PADT (PC), the connection can be established with a Route add entry on the

PC.

The key can be accessed through a small round hole located approximately 5 cm from the

upper left-hand side of the housing. The key is engaged using a suitable pin made of insulating

material to avoid short-circuits within the controller.

The reset is only effective if the controller is rebooted (switched off and on) while the key is

simultaneously engaged for at least 20 s. Engaging the key during operation has no effect.

Properties and behavior of the controller after a reboot with engaged reset key:

Connection parameters (IP address and system ID) are set to the default values.

All accounts are deactivated except for the administrator default account with empty

password.

Loading a user program or operating system with default connection parameters is inhibited!

The loading procedure is only allowed after the connection parameters and the account have

been configured on the controller and the controller has been rebooted.

After a new reboot without the reset key engaged, the connection parameters (IP address and

system ID) and accounts become effective.

Those configured by the user.

Those valid prior to rebooting with the reset key engaged, if no changes were performed.

3.4.4 Hardware Clock

In case of loss of operating voltage, the power provided by an integrated capacitor is sufficient

to buffer the hardware clock for approximately one week.

Start-up

To start up the controller, it must be mounted, connected and configured in SILworX.

4.1 Installation and Mounting

The controller is mounted on a 35 mm DIN rail such as described in the system manual for

compact systems.

When laying cables (long cables, in particular), take appropriate measures to avoid interference,

e.g., by separating the signal lines from the power lines.

When dimensioning the cables, ensure that their electrical properties have no negative impact

on the measuring circuit.

4.1.1 Connecting the Digital Inputs

Use the following terminals to connect the digital inputs:

Surges on Digital Inputs

Due to the short cycle time of the HIMatrix systems, a surge pulse as described in

EN 61000-4-5 can be read in to the digital inputs as a short-term high level.

The following measures ensure proper operation in environments where surges may occur:

1. Install shielded input wires

2. Program noise blanking in the user program. A signal must be present for at least two cycles

before it is evaluated. The fault reaction is triggered with a corresponding delay.

i The measures specified above are not necessary if the plant design precludes surges from

occurring within the system.

In particular, the design must include protective measures with respect to overvoltage,

lightning, earth grounding and plant wiring in accordance with the relevant standards and the

instructions specified in the system manual (HI 800 141 E or HI 800 191 E).

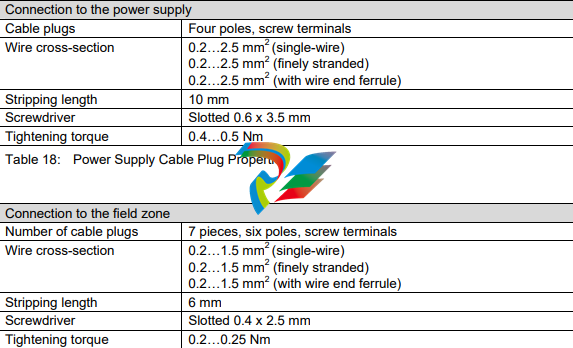

Cable Plugs

Cable plugs attached to the pin headers of the devices are used to connect to the power supply

and to the field zone. The cable plugs are included within the scope of delivery of the HIMatrix

devices and modules.

The devices power supply connections feature the following properties:

Sequence of Events Recording (SOE)

The global variables of the controller can be monitored using sequence of events recording.

Global variables to be monitored are configured using SILworX, see the online help and the

SILworX communication manual (HI 801 101 E). Up to 4000 events can be configured.

An event is composed of:

.png)

.png)

.png)