Woodward 505 Digital Controller For steam turbineses

8200-1300. 8200-1301. 8200-1302

505 Digital Controller

For steam turbines

8200-1300. 8200-1301. 8200-1302

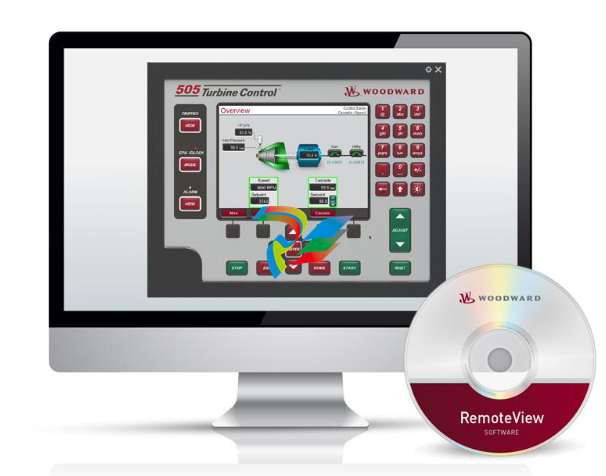

This chapter provides a brief introduction to other Woodward devices that are easy to integrate with the 505. By understanding the peripheral devices

The functions of the equipment can help you better understand the overall control configuration.

Some of these devices CAN communicate with each other via a digital communication link (Ethernet or CAN, depending on the product)

Connect 505. Through this link, the 505 monitor will allow users to monitor many things from this external device

Signal and status LED. In many cases, these connections allow the 505 to receive the required input signals, for example

Such as KW load signals or synchronization or load distribution bias signals. This eliminates the need to wire these signals to typical ones

The demand for I/O channels, or digital signals can be used as redundant/backup signals for hardwired signals.

Devices supported within the 505 control application will be identified as the "Woodward Link" identifier

All the equipment covered in this section is manufactured or supported by Woodward. Peripheral devices manufactured by other companies are acceptable

Used in conjunction with 505 to perform the following functions, however, they should be confirmed to be compatible with 505 before system operation

And the compatibility of the application.

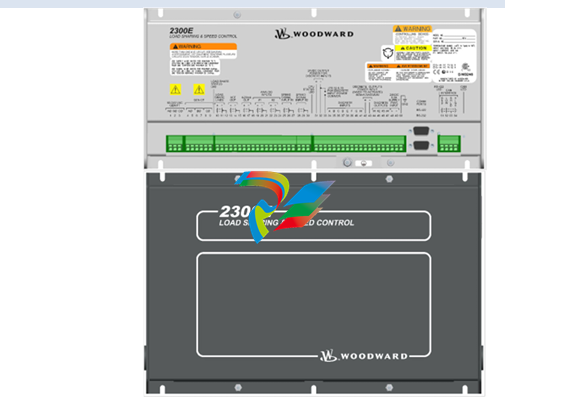

When DSLC-2 is connected to the 505 controller, it can be used together with a generator to accurately detect three phases

The output power of the RMS generator is synchronized with the actuator generator circuit breaker. Other configurable DSLC-2 feature packs

Including generator load distribution, VAR or power factor control, process control and basic load control.

Woodward 505 digital governor for steam turbines with single or split actuators

This is a "Woodward Link" device.

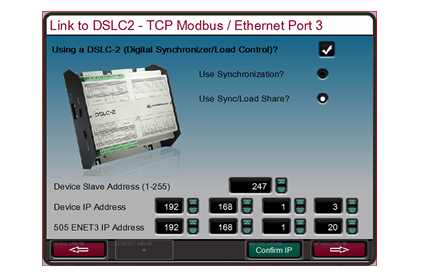

To enable the Woodward Link feature, select the selection box on the above screen, enter the slave address and DSLC-2 Settings

The prepared IP address. The above figure shows the factory default IP addresses of the DSLC-2 and Ethernet port 3 of the 505.

Once the Ethernet port 3 of the 505 and the network port B of the DSLC-2 are connected with an RJ45 cable

Next, these Settings will allow the two products to communicate automatically.

Once this configuration is completed, DSLC-2 can provide synchronous speed bias signals and synchronous/load distribution bias signals

And the KW output of the generator. The radio buttons on the screen allow users to select the desired functions. Through this chain

The KW valued by the path can be used as an auxiliary KW input signal and is a pre-configured analog input for the KW input

Entry passage.

The following screen shows the available service screens, which can now be accessed for monitoring DSLC-2.

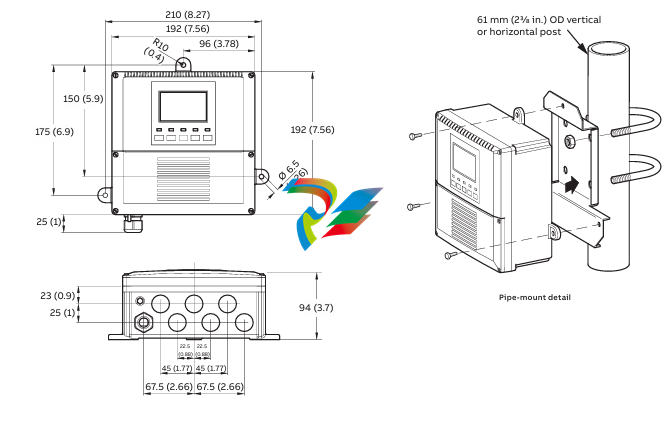

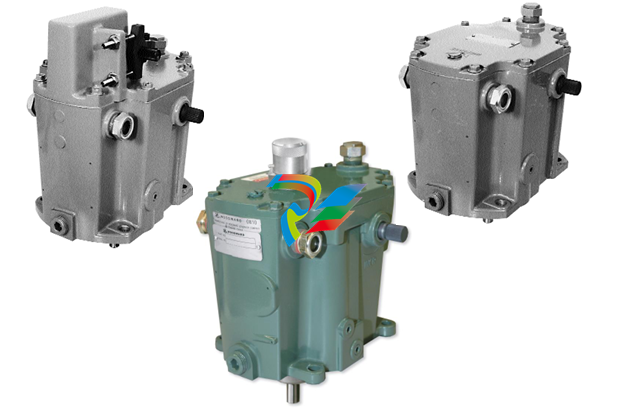

VariStroke-II is a linear electronic-hydraulic actuator designed to provide control valves for operating steam turbines

Or the linear actuator of the valve frame. This actuator can be directly networked with the 505 controller to reduce

Low system complexity and wiring requirements.

To enable the Woodward Link feature, select the selection box on the above screen to enable CAN1 Link and confirm

Use the VariStroke II actuator and then enter the device ID. If an analog (4-20 mA) requires a letter

If the signal is about to be connected to the CAN link and VariStroke, then select the desired function for this signal (recommended)

AI as a backup. Finally, select the steam inlet valve being controlled (for most applications, it is an HP requirement).

This is a "Woodward Link" device.

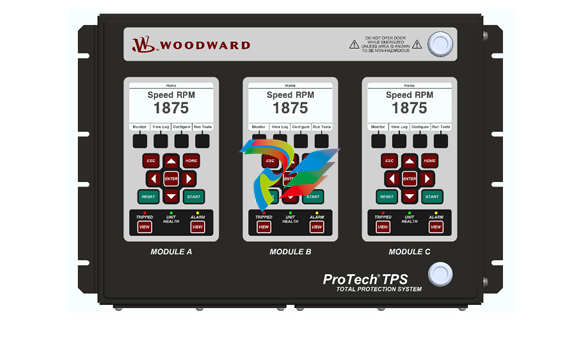

The MFR 300 is a multi-functional generator protection relay used for detecting and protecting small generators. This is quite a lot.

The functional protection relay integrates all generator protection functions in a common device, reducing the overall system

Installation replicability and cost.

This is a "Woodward Link" device.

The LS-5 series protection relay integrates the synchronization, power detection and protection functions of the generator circuit breaker into one. This assumption

It is designed to function in conjunction with a prime mover controller similar to the 505 to allow for accurate generator operation

Control and provide the required generator protection.

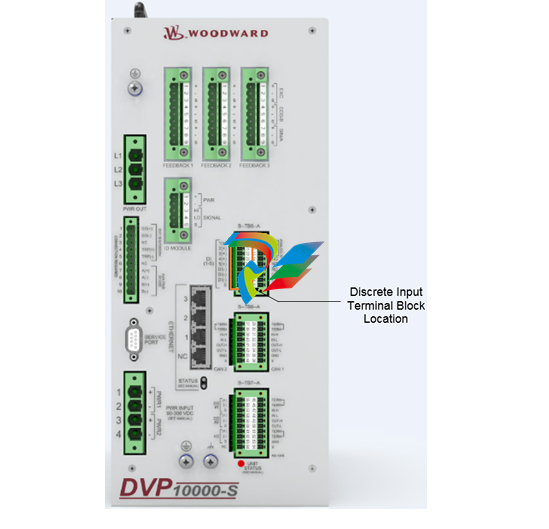

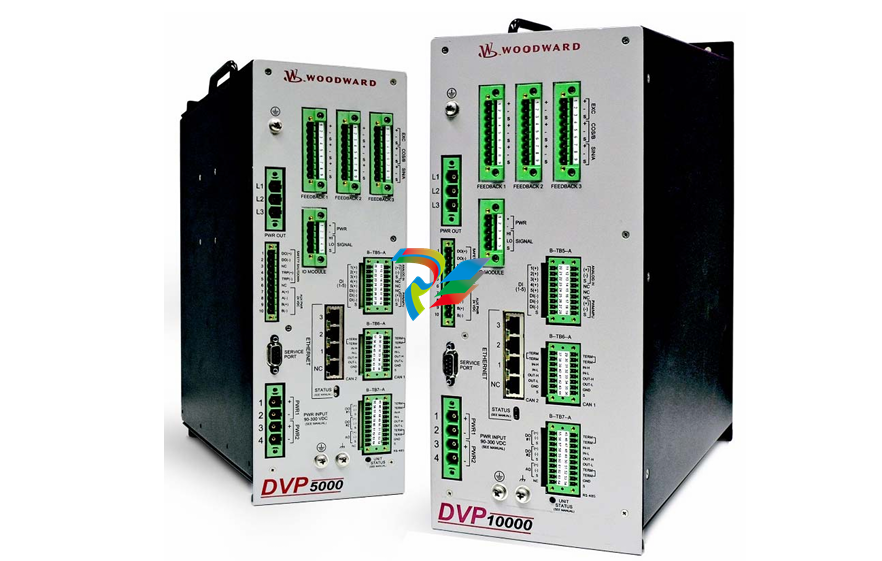

Servo mechanism Position Controller (SPC

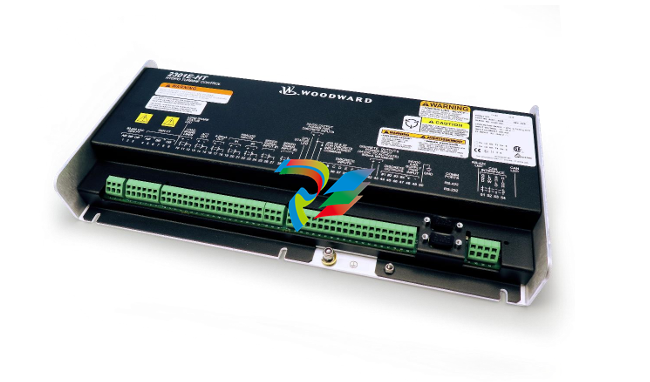

The servo mechanism position controller (SPC) can be used to connect the 505 digital controller to the existing valve actuator

Or integrate actions or Woodward actuators that are not directly compatible with 505.

The actuator output of 505 is capable of driving a ratio of 4-20 mA or 20-160 mA (up to 200 mA)

The signal enters an actuator coil. These actuator output signals represent the equivalent of the desired valve position (ratio)

For example, the required signal. If the actuator or servo mechanism assembly of the steam turbine requires a different drive signal,

Or control actions (integrated with invalid Settings), a SPC or equivalent device must be used.

Woodward servo position Controller (SPC) accepts 4-20 mA actuation proportional to the desired valve position

The driving signal of the actuator is activated, and a servo mechanism assembly is correspondingly installed. Woodward SPC is capable

.png)

.png)