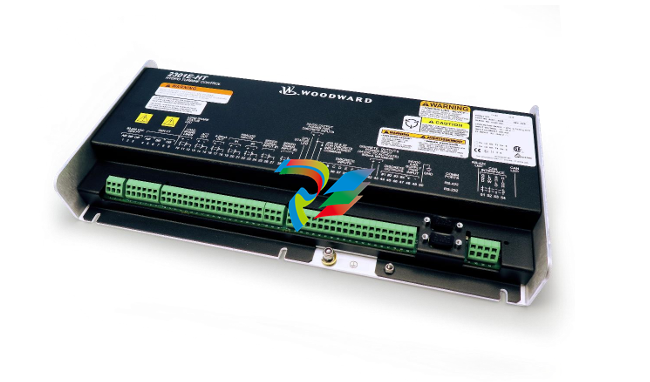

Woodward 505 Digital Controller For steam turbineses

8200-1300. 8200-1301. 8200-1302

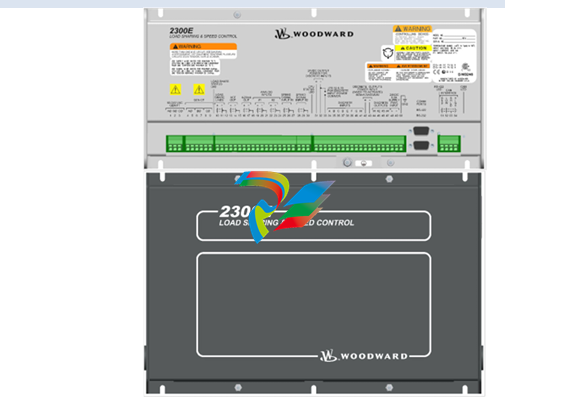

Automatic switching is based on configured I/O (see available I/O options). If a converter is configured, then

If the input is discrete, it is used for fault alarm and automatic switching.

Properly installed valves allow for online converter replacement.

For more information about Woodward's redundant CPC products, refer to Manual 26448 and consult your sales representative

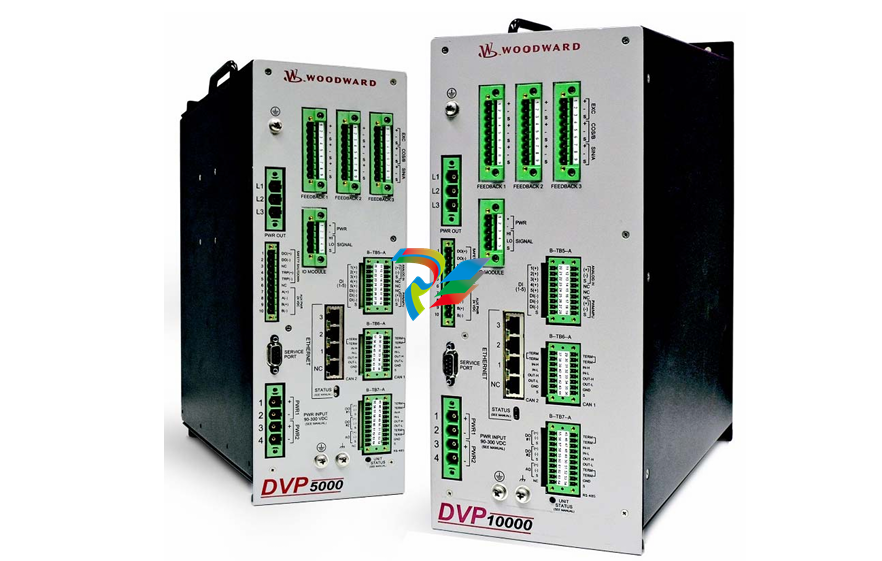

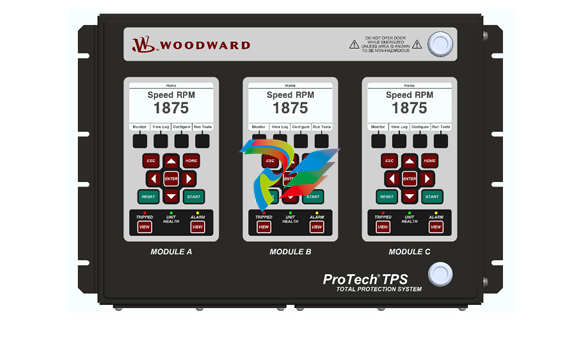

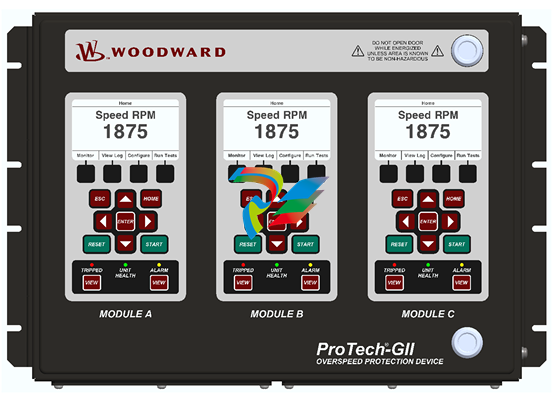

Represent all CPC products.

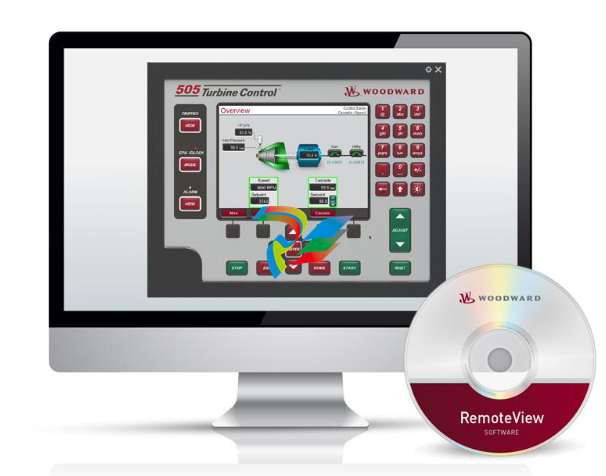

This chapter is designed to provide users with a concept of the capabilities of the 505 electronic controller and how to apply it in the system

They. Typical applications are all presented in the chart, and their functions are also explained. Each application is equipped

Set and start/run mode annotations to assist application configurators in configuring 505 for their own applications. "Basic"

The device connection is displayed in each application drawing to allow for an understanding of how these devices are connected to the 505 and expanded

Show your abilities.

Speed/Load PID

The speed PID can be controlled and limited

Unit speed/frequency

Unit load

When operating in a solitary network, the speed PID of 505 can be used to control the speed/frequency of the unit and is parallel to the infinite bus

When the power grid is connected in parallel, it can be used to control the load of the unit. The speed PID can be configured to output signals through its actuator

The unit load is detected by the 4-20mA analog input signal from the generator power sensor or the number. When configured to be on

When detecting and controlling the generator load through analog input, what is detected and controlled is the real unit load. By making

The control is carried out by the generator load signal, and any difference in the intake or exhaust pressure of the steam turbine is detected and obtained

Compensation, thereby providing true load control.

The combination of the speed PID and its set value limit allows this PID to limit the unit load. When used as a load limiter for the unit

At that time, it is recommended to configure the 505 to only detect and control the actual generator load. If 505 is applied to soft power

net

Due to the large variations in grid frequency, it is recommended to use auxiliary PID rather than speed PID to limit the load of the unit.

Auxiliary PID

The auxiliary PID of 505 can be configured to control or limit:

Steam turbine inlet pressure

Steam turbine inlet flow rate

Steam turbine exhaust pressure

Steam turbine exhaust flow

Generator power output

Input/output power of power plants or lines

Process temperature

Inlet pressure of the compressor

Inlet flow rate of the compressor

Outlet pressure of the compressor

Outlet flow rate of the compressor

Any process parameters related to the unit load, intake steam pressure/flow rate, exhaust steam pressure/flow rate (depending on the configuration

"Place

The auxiliary PID of 505 can be used as a limiter or controller (enabled and disabled according to instructions). When the configuration is the limit

When making the device, the output of this PID is a low-signal selection compared to the output of the rotational speed PID. This configuration allows for auxiliary PID

Limit the load of the unit based on the detected parameters.

When the auxiliary PID is configured as a controller, it must be accessed through the 505's front panel, contact input, or Modbus

Enable and disable the given instructions. After setting it up in this way, when the auxiliary PID is enabled, the speed PID is disabled

Use and track the output of the auxiliary PID.

To control or limit any of the listed parameters, the 505 must be configured to accept an auxiliary analog input representing the parameter level

Input signal. The exception to this principle is that when controlling or limiting the generator load, the auxiliary PID can be configured to enable

Use and share the KW/ unit load with the speed PID.

Cascade PID

The cascade PID of 505 can be configured for control:

Steam turbine inlet pressure

Steam turbine inlet flow rate

Steam turbine exhaust pressure

Steam turbine exhaust flow

Generator power output

Input/output power of power plants or lines

Process temperature

Inlet pressure of the compressor

Inlet flow rate of the compressor

Outlet pressure of the compressor

Outlet flow rate of the compressor

Any process parameters related to the unit load, intake steam pressure or exhaust steam pressure (depending on the configuration

The cascade PID of 505 can be used to control any of the listed parameters. This PID must pass in front of 505

Enable and disable based on the board, contact input or instructions given by Modbus.

Cascade PID and speed PID cascade are used to change the speed/load of the unit. By directly locating the speed PID

The set value, cascade PID can change the unit speed/load to the controller input parameter. This configuration allows for up to two

Disturbance-free switching is performed between two control modes (speed/load and cascade).

Sample application

The sample applications in this chapter will not demonstrate every possible control configuration or combination. However, these examples can also serve as references

Examine to apply any control combinations or parameters that are not listed or displayed. Apply a control that is desired but not displayed

.png)

.png)