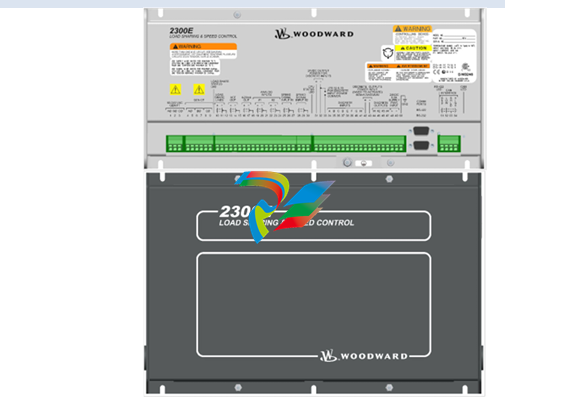

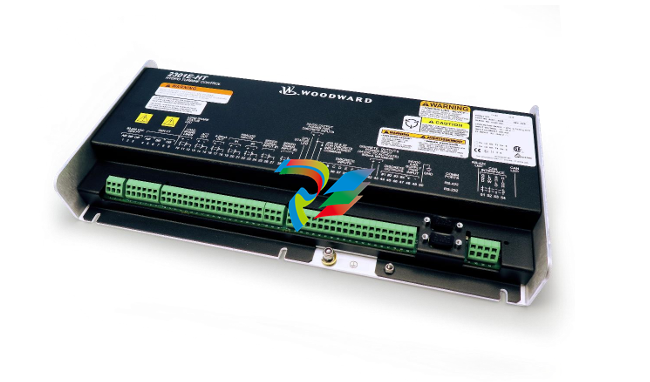

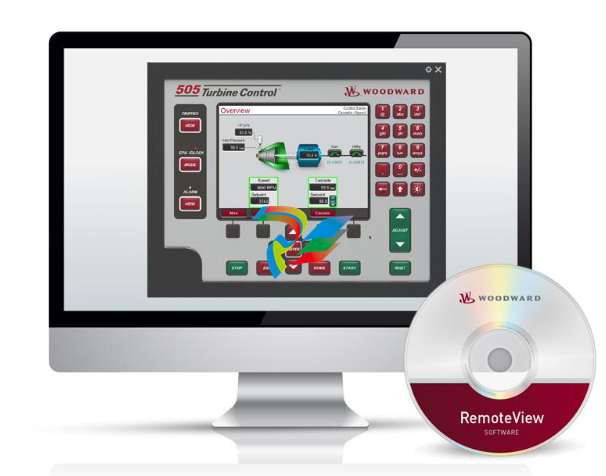

Woodward 505 Digital Controller For steam turbineses

8200-1300. 8200-1301. 8200-1302

The setting, or process control mode, depends on the configuration and system conditions.

The load distribution mode of EGCP-3 LS is used to distribute loads to those using EGCP-3 LS and tied to the same isolation busbar

Any other units of the line. When connected in parallel to the power grid, this mode is used together with EGCP-3 MC to allow

The EGCP-3 MC controls the frequency or load of the power plant depending on its operating status.

The remote load setting mode of EGCP-3 LS allows a remote 4-20 mA signal to set the load. EGCP

The process control mode of 3LS allows for the control of any process directly related to the generator load.

After synchronization, it can be obtained by EGCP-3 LS (via 505 synchronization/load input) or by the internal speed of 505 /

The load setting value controls the load of the unit. When configuring the synchronous/load input, the position of the contacts of the power grid circuit breaker is open

Select the unit load control through the internal load setting values of EGCP-3 LS or 505.

Once the generator is synchronized with the EGCP-3 LS software load, the unit to the load setting has an operating mode (base load,

Load distribution and process control have been determined. Upon receiving the instruction, EGCP-3 LS can also perform software unloading on the unit

Negative, simultaneously issue a circuit breaker disconnection command at a set power level.

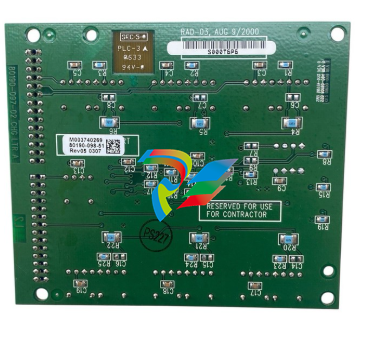

The PowerSense board receives PT and CT inputs for the generator and busbar to be used within the system controller

The parameters were calculated using EGCP-3. The algorithm used is based on IEEE 1459-2000. For the generator and busbar

The following parameters are provided: Hz, Vac, Amps, W, VA, VAR, PF, phase, voltage modulation, and electricity

Current regulation, negative phase sequence voltage, negative phase sequence current. In the 4-20mA analog output, optional: synchronous oscilloscope,

Generator measurement, main line measurement.

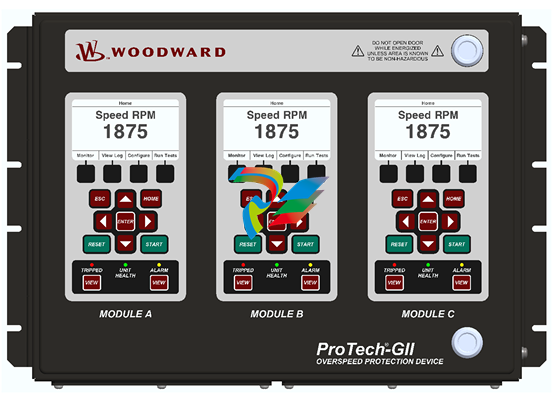

EGCP-3 LS is equipped with the following busbar protection:

Overvoltage/undervoltage (59.27)

Overfrequency/underfrequency (81O, 81U)

Directional (forward/reverse) power (32) *

Negative sequence overcurrent (46

Negative sequence overvoltage (47

Phase overcurrent (51) *

Voltage limiting phase overcurrent (51V) *

Directional VAR

Phase current imbalance (46

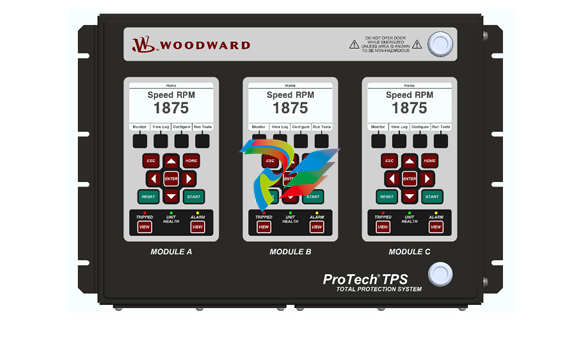

The EGCP-3 LS is equipped with the following generator protections:

Overvoltage/undervoltage (59.27)

Overfrequency/underfrequency (81O, 81U)

Directional (input/output) power (32) *

Negative sequence overcurrent (46

Negative sequence overvoltage (47

Phase overcurrent (51) *

Directional VAR

Phase current imbalance (46) *

The rotational speed/frequency is mismatched

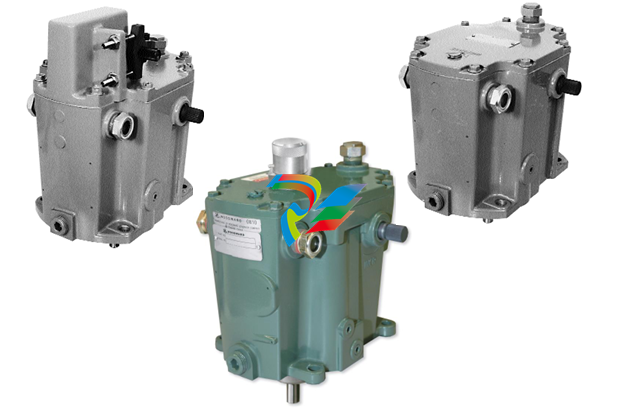

Apply 505 in conjunction with redundant I/H or I/P converters

505 can be applied in simplex or redundant actuator systems. For redundant actuator applications, actuators

Channel 1 is configured to lead for HP instructions, and Channel 2 is configured for zero-bias HP2 requirements. this

It will provide the full current from the two actuator drive circuits to the driven device

The selection between the output signals of the converter can be accomplished by using an edge valve or a solenoid delivery valve. Converter status (I/H

Or I/P and pressure feedback signals can be selectively configured into the 505. If necessary, the relay output can be configured

Switch between the outputs of the converter. Manual switching between converters can be achieved through discrete input and Modbus

Or use the PC interface command to start. The automatic switching between converters is carried out by 505 based on drive failure and conversion

The feedback signals of the device status, the output pressure of the converter and the input pressure of the servo mechanism are provided.

Functional details

The use of a dual-actuator configuration can provide redundancy up to the actuator level. A typical redundant I/H (or I/P) system

The milliampere output of the 505 actuator will be converted into the corresponding hydraulic (or pneumatic) pressure of the positioning servo mechanism cylinder

Force. Both converters supply the appropriate pressure to position the steam valve as required by the controller. One of the conversions

One will control the valve position requirements, while the other will be in standby mode. The selection between the output signals of the converter can be made using edges

It can be accomplished by using a valve or a solenoid conveyor valve. The edge valve will select the higher pressure output of the two converters, the solenoid transfer valve

Then select the output of one converter and switch between the two converters based on the relay command from the 505 controller

Change. Either type of valve can be used. Refer to the conveyor valve section for the respective advantages of the two types of valves

Information on strengths/weaknesses.

The converter status (I/H or I/P) and pressure feedback signals should be configured into 505 because of the automatic between converters

Switching is provided and handled by the states of these signals. If necessary, a relay output can be configured (configuration)

It is a relay that serves a control function to switch between the outputs of the converter.

.png)

.png)