FOXBORO Z-Module Control Processor 270 (ZCP270)

FOXBORO Z-Module Control Processor 270 (ZCP270)

Z-Module Control Processor 270 (ZCP270)

The Z-Module Control Processor 270 is a distributed, optionally fault-tolerant controller that performs

process control and alarming functions according to a user-defined control strategy.

FEATURES

Performs regulatory, logic, timing, and sequential

control together with connected Fieldbus

Modules

Supports up to 128 of the 200 Series Fieldbus

Modules (FBMs - Compact or standard types)

when using the FCM100Et Fieldbus

Communications Module

Supports up to 128 of the 200 Series FBMs

(Compact or standard types), 100 Series FBMs,

or a combination 100 Series and 200 Series

FBMs when using the FCM100E Fieldbus

Communications Module

Performs data acquisition and alarm detection

and notification

Offers unique, patented, fault-tolerant operation

using two control modules to greatly improve

reliability relative to other process controllers

Connects to The MESH control network via

standard fiber optic 100 Mbps Ethernet

Uses versatile control algorithms and a wide

variety of FBMs to provide control capabilities for

a broad range of process applications

Supports time synchronization using optional

external time from GPS satellites

Offers on-line image update of a fault-tolerant

ZCP270 without shutting down the process

Uses soft letterbugs configurable via the

I/A Series® system Letterbug Configurator.

Supports self-hosting mode with I/A Series

software v8.4-v8.8 or Foxboro Evo™ Control

Core Services v9.0 or later

OVERVIEW

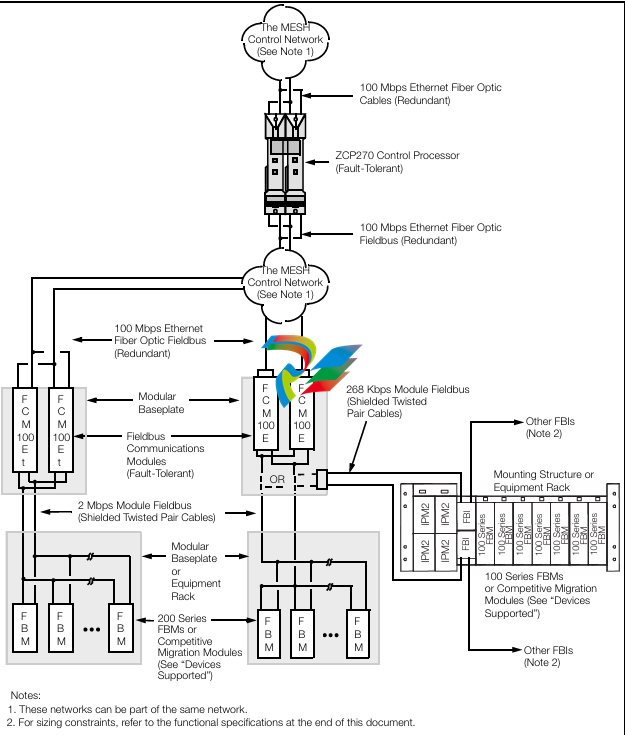

The Z-Module Control Processor 270 (ZCP270) is an

optionally fault-tolerant, Z-form factor controller. The

ZCP270 performs regulatory, logic, timing, and

sequential control together with connected Fieldbus

Communications Modules (FCMs) and Fieldbus

Modules. It also performs data acquisition and alarm

detection and notification. The ZCP270 connects to

The MESH control network and

FCM100Ets/FCM100Es via standard fiber optic 100

Mbps Ethernet. The FCM100Et interfaces the

2 Mbps Module Fieldbus used by the 200 Series

FBMs and the FCM100E interfaces the 2 Mbps

Module Fieldbus used by the 200 Series FBMs or the

268 Kbps Fieldbus used by 100 Series FBMs.

Depending on sizing considerations, the ZCP270 can

be used with a mix of FCM100E and FCM100Et

modules.

The fault-tolerant version of the ZCP270 consists of

two single-width processor modules. These modules

install in adjacent ZCP270 slots in a 1x8 or 2x8

mounting structure and connect to a fault-tolerant

connector to allow for high-speed communication

between the modules (see Figure 1).

EQUIPMENT MOUNTING

The Foxboro Evo architecture requires workstations

and commercial-off-the-shelf (COTS) Ethernet

switches, a rack room for the ZCP270 and Ethernet

switches, and a field enclosure for the

FCM100Ets/FCM100Es, FBMs, and other I/O

hardware. For more information on The MESH

control network architecture, refer to

PSS 21H-7C2 B3.

ENHANCED RELIABILITY (FAULT

TOLERANCE)

The unique and patented fault-tolerant operation of

the ZCP270 greatly improves reliability relative to

other process controllers. The fault-tolerant version of

the ZCP270 consists of two modules operating in

parallel, with two sets of Ethernet connections to The

MESH network, two for the control network and two

for the fieldbus network. The two ZCP270 modules,

married together as a fault-tolerant pair, provide

continuous operation of the controller in the event of

virtually any hardware failure occurring within one

module of the pair.

Both modules receive and process information

simultaneously, and faults are detected by the

modules themselves. One of the significant methods

of fault detection is comparison of communication

messages at the module external interfaces.

Messages only leave the controller when both

controllers agree on the message being sent (bit for

bit match). Upon detection of a fault, self-diagnostics

are run by both modules to determine which module

is defective. The non-defective module then assumes

control without affecting normal system operations.

This fault-tolerant solution has the following major

advantages over controllers that are merely

redundant:

No bad messages are sent to the field or to

applications using controller data because no

message is allowed out of the controller unless

both modules match bit for bit on the message

being sent.

The secondary controller is synchronized with the

primary one, which ensures up to the moment

data in the event of a primary controller failure.

The secondary controller will have latent flaws

detected prior to any switchover because it is

performing exactly the same operations as the

primary controller.

SPLITTER/COMBINER

Fault-tolerant ZCP270 modules connect to two pair

of fiber optic splitter/combiners (see Figure 1). One

splitter/combiner pair connects redundant Ethernet

ports on the front of each module to redundant

Ethernet switches in the control network. The other

splitter/combiner pair connects redundant Ethernet

fieldbus ports on the top of each module to

redundant Ethernet switches in the control network.

For each module, the splitter/combiners provide

separate transmit/receive fiber connections for each

Ethernet control network and Ethernet fieldbus port.

Fiber cables are connected so that splitter/combiners

pass inbound traffic from a switch to both modules,

and pass outbound traffic from the primary module

to a switch.

Each splitter/combiner pair mounts in an assembly

that either mounts in a chassis assembly for 19-inch

racks or fastens to the DIN rail in the enclosure. The

splitter/combiner is a passive device that does not

require electrical power.

ENHANCED COMMUNICATIONS

The Foxboro Evo architecture uses an Ethernet

control network with 100 Mbps data

communications between the ZCP270s and the

Ethernet switches (see Figure 2).

The ZCP270 can also communicate with serial and

Ethernet devices, such as PLCs, via Field Device

System Integrators and FCM100Ets/FCM100Es. This

allows connection to new device interfaces without

any changes to the controller software.

ON-LINE IMAGE UPDATE

For fault-tolerant ZCP270 modules, on-line image

update replaces the executable image (operating

system) of a running ZCP270 with a newer image

without having to shut down the equipment being

controlled by the ZCP270. New product

enhancements can be brought on-line in

1.5 seconds for heavily loaded controllers; less for

lightly loaded controllers.

Because the ZCP270 contains its executable image

in internal flash memory, and has sufficient RAM to

hold a new executable image at the same time, on

line image updates are now much easier to perform.

TIME SYNCHRONIZATION, SOE, TDRA

The Foxboro Evo system supports time

synchronization using either an externally maintained

optional source of Universal Coordinated Time (UTC)

from GPS satellites or an internal source using

proprietary software. ZCP270s and their FCM100Ets

receiving time updates via the external time source

synchronize their FBMs to 1 ms. For more

information, refer to PSS 21S-1C2 B3.

Time stamping is used for alarm messages, values

sent to the historian, and the new Sequence Of

Events (SOE) and Transient Data Recorder and

Analyzer (TDRA) features.

SOE data are discrete points that are time stamped

at the FBM, optionally to 1 ms, and sent to the

workstation on a change basis. TDRA data are

analog points that are time stamped at the FBM and

sent to the workstation every 10 ms. These new

features are supported by client software in the

workstation. To support SOE and TDRA, the

FCM100Et must be installed on the same network as

the workstation collecting the data. For information

on this software, refer to PSS 21S-2B9 B4 and

PSS 21S-2B10 B4

SOFTWARE FEATURES

The ZCP270 performs regulatory, logic, timing, and

sequential control, as well as data acquisition, alarm

detection, and alarm notification. Process variables

are controlled using time-proven algorithms

(mathematical computations performing specific

functions). The algorithms are contained in functional

control blocks, which are configured by on-site

process engineers to implement the desired control

strategies. The versatility of the algorithms, coupled

with the variety of FBMs available, provides control

capabilities suited to a broad range of process

applications. Control strategies ranging from simple

feedback and cascade loops to highly sophisticated

feedforward, nonlinear, and complex characterization

control schemes are readily implemented.

The ZCP270 also provides the following features:

Infrared communications with the controller

enables you to set and read the controller

letterbug via the Letterbug Configurator.

Alarm enhancements to the function blocks:

re-alarming on changes to alarm priority,

re-alarming based upon a configurable time delay

deadband, and alarm suppression based upon

time.

Optional UTC external time synchronization.

Improved controller performance.

Optional self-hosting mode (I/A Series software

v8.4-v8.8 or Control Core Services v9.0 or later)

allows the ZCP270 to start up and run, executing

its configured control scheme using the

checkpoint file stored in flash memory. This

allows the ZCP270 to boot itself with a valid

control database even if its host workstation is

not present.

Self-Hosting Feature, Available with 200 Series

FBMs Only

The self-hosting feature is recommended only for use

in ZCP270s which are used with 200 Series FBMs.

All of the information necessary to reboot 200 Series

FBMs is included in non-volatile flash memory on the

ZCP270. However, the flash memory on the

100 Series FBMs and related products on the 268k

fieldbus does not include this information, and they

require the workstation host to be present to reboot.

More details on the self-hosting feature are available

in DIN Rail Mounted FBM Subsystem User’s Guide

(B0400FA).

DEVICES SUPPORTED

The ZCP270 with FCM100Ets supports the following

devices:

All 200 series FBMs (FBM201. FBM202. and so

forth)

Field Device Systems Integrator (FDSI) modules

Intrinsically Safe I/O Subsystem (ISCM)

DCS Fieldbus Modules for Siemens APACS+™

Systems

DCS Fieldbus Modules for Westinghouse

WDPF® Systems.

DCS Fieldbus Modules for Fisher's PROVOX®

Series 20 Migration with HART.

DCS Fieldbus Modules for Honeywell® TDC

2000 Systems with HART.

The ZCP270 with FCM100Es supports the following

devices on the 2 Mbps module Fieldbus:

All 200 Series FBMs (FBM201. FBM202. and so

forth) - both Compact or standard types

Field Device Systems Integrator (FDSI) modules

Intrinsically Safe I/O Subsystem (ISCM)

DCS Fieldbus Modules for Siemens APACS+™

Systems

DCS Fieldbus Modules for Westinghouse

WDPF® Systems.

DCS Fieldbus Modules for Fisher's PROVOX®

Series 20 Migration with HART.

DCS Fieldbus Modules for Honeywell® TDC

2000 Systems with HART.

The ZCP270 with FCM100Es supports the following

devices on the 268 Kbps Fieldbus:

100series FBMs (FBM01. FBM02. and so forth)

Fieldbus Cluster I/O via FBP10 Fieldbus

processor module

Foxboro® Hydrostatic Interface Unit (HIU)(1)

Foxboro Mass Flowmeter

Foxboro Panel Display Stations

SPECTRUM™ Migration Integrators

SPEC 200™ Control Integrators

SPEC 200 MICRO™ Control Integrators

SPEC 200 CCM Control Integrators

DCS Fieldbus Modules for Honeywell® TDC 2000

and TDC 3000 systems

DCS Fieldbus Modules for Bailey® Net90 and

Infi90 systems

DCS Fieldbus Modules for Fisher’s PROVOX®

Series 10. Series 20 and Controller Series

systems.

MOUNTING STRUCTURE

The ZCP270 are installed in the 1x8 and 2x8

mounting structures. The two modules of a fault

tolerant ZCP270 must be mounted in adjacent

mounting structure slots to allow for installation of the

interconnecting fault-tolerant connector

LED INDICATORS

Light-emitting diodes (LEDs) on the front of the

ZCP270 module provide visual indication of the:

ZCP270 operational status

Communications activity of Ethernet control

network A and B links

Communications activity of Ethernet fieldbus A

and B.

The control network path Tx LEDs indicate which

controller is primary as well as the network path it is

using; these LEDs are only active on the primary

module

FUNCTIONAL SPECIFICATIONS

Processor Type

CONTROL PROCESSOR

Microprocessor-based AMD Elan SC520 (running

at 100 MHz) with stored programs, using high

speed communication capability.

Memory (per processor)

SIZE

16 MB SDRAM

32 MB flash memory

ERROR DETECTION

ECC providing single-bit error detection and

correction as well as multiple-bit error detection.

Process I/O Communications (with FCMs)

100 MBPS FAST ETHERNET

Transmission Rate

100 Mbps to the FCM100Et or FCM100E

Cable Lengths

ZCP270. FCM100Et or FCM100E TO

ETHERNET SWITCH

2 km (1.24 mi) maximum

Process I/O Capacity

WITH FCM100Et

FCM100Et Modules

32 (maximum) per ZCP270 Ethernet trunk

fieldbus

200 Series FBMs

128 (maximum) Fieldbus Modules depending

on the number of FCM100Ets implemented

and control processor sizing constraints

(refer to ZCP270 Sizing Guidelines

[B0700AW]).

WITH FCM100E

FCM100E Modules

32 (maximum) per ZCP270 Ethernet trunk

fieldbus

200 Series FBMs

128 (maximum) Fieldbus Modules depending

on the number of FCM100Es implemented

and control processor sizing constraints

(refer to ZCP270 Sizing Guidelines

[B0700AW]).

WITH FCM100E (CONT.)

100 Series FBMs

64 (maximum) per ZCP270 Ethernet trunk

128 (maximum) Fieldbus Modules depending

on the number of FCM100Es implemented

and control processor sizing constraints

(refer to ZCP270 Sizing Guidelines

[B0700AW]).

Maximum Number of Blocks Configured

The maximum number of blocks that can be

configured for the ZCP270 (or fault-tolerant ZCP270

pair) is 4000.

Memory Allocation for Blocks

5.8 MB

Block Executions Per Second

10.000 blocks/second, maximum

Maximum Blocks Processed

The number of blocks that can be processed per

basic processing cycle (BPC) time interval depends

on control processor sizing constraints and block

type selection. These blocks include all types (control

blocks, ECBs, compounds, data blocks, and so

forth). For sizing guidelines, refer to ZCP270 Sizing

Guidelines (B0700AW).

Minimum Block Processing Cycle (BPC)

50 ms

Sequence Block Size

32 KB maximum for each block

Maximum Number of IPC Connections

131; 100 connections for source points; 30

connections for sink points; 1 connection for internal

use only.

30 IPC connections

100 IPC connections

ZCP270

Maximum Number of OM Sink Lists

50

Maximum OM Scanner Database

12.000 points for BPC ≥ 200 ms

5.000 points for BPC ≤ 100 ms

FUNCTIONAL SPECIFICATIONS (CONTINUED)

Maximum Number of OM Sink Points

7.500

Configurable Block Periods

0.05. 0.1. 0.2. 0.5. 0.6. 1. 2. 5. 6. 10. 30 seconds

1. 10. 60 minutes

Basic Processing Cycle

0.05. 0.1. 0.2. 0.5. and 1.0 seconds, selectable at

system configuration time

Time to Marry Fault-Tolerant Modules

<1s

Internal Diagnostics

Self-checking performed at power-up. Run-time

checks and the watchdog timer function performed

during operation.

Infrared Communications

Letterbug assignment via the Letterbug Configurator.

Letterbug or Hardware ID readout via the Letterbug

Configurator.

Power Requirements

INPUT VOLTAGE (REDUNDANT VOLTAGE)

39 V dc typical

CONSUMPTION (PER NON-FAULT-TOLERANT

MODULE)

15 W, maximum

Regulatory Compliance

CE CERTIFICATION

For the ZCP270 to meet CE certifications

required in European installations, shielded

enclosures are required as described in Power,

Earthing (Grounding), EMC and CE Compliance

(B0700AU).

ELECTROMAGNETIC COMPATIBILITY (EMC)

European EMC Directive 89/336/EEC

Meets: EN 50081-2 Emission standard

EN 50082-2 Immunity standard

EN 61326 Annex A for Industrial

Environments

Regulatory Compliance (Continued)

CISPR 11. Industrial Scientific and Medical

(ISM) Radio-frequency Equipment -

Electromagnetic Disturbance Characteristics - Limits and Methods of Measurement

Meets: Class A Limits

IEC 61000-4-2 ESD Immunity

Contact 6 kV, air 8 kV

IEC 61000-4-3 Radiated Field Immunity

10 V/m at 80 to 1000 MHz

IEC 61000-4-4 Electrical Fast

Transient/Burst Immunity

±2 kV on I/O, dc power and communication

lines

IEC 61000-4-5 Surge Immunity

±2 kV on ac and dc power lines; ±1 kV on

I/O and communications lines

IEC 61000-4-6 Immunity to Conducted

Disturbances Induced by Radio-frequency

Fields

10 V (rms) at 150 kHz to 80 MHz on I/O,

dc power and communication lines

IEC 61000-4-8 Power Frequency Magnetic

Field Immunity

30 A/m at 50 and 60 Hz

SECURITY

Wurldtech Achilles Certification™ Level One

ENVIRONMENTAL SPECIFICATIONS(2)

Operating

TEMPERATURE

0 to +60°C (+32 to +140°F)

RELATIVE HUMIDITY

5 to 95% (Noncondensing)

ALTITUDE-300 to +3.000 m (-1.000 to +10.000 ft)

VIBRATION

0.5 g (5 to 500 Hz)

Configuration

Single-width processor module. The fault-tolerant

version consists of two single-width processor

modules, with an interconnecting fault-tolerant

connector.

Mass (Maximum)

1.7 kg (3.75 lb) for a single, non-fault-tolerant module.

Mounting

May be placed in any of the following I/A Series

mounting structures:

1x8 Mounting Structure

2x8 Mounting Structure(3)

In the fault-tolerant version, the two modules must be

mounted in adjacent mounting structure slots to allow

for installation of the interconnecting fault-tolerant

connector.

Dimensions - Module

HEIGHT

228 mm (8.97 in)

WIDTH

34.3 mm (1.35 in)

DEPTH

447 mm (17.6 in)

Storage

TEMPERATURE-40 to +70°C (-40 to +158°F)

RELATIVE HUMIDITY

5 to 95% (Noncondensing)

ALTITUDE-300 to +12.000 m (-1.000 to +40.000 ft)

PHYSICAL SPECIFICATIONS

Fiber Optic Cabling – Ethernet Switch to

ZCP270

CONNECTORS

Ethernet Switch Connector

One MT-RJ Connector

ZCP270 or Splitter/Combiner Connector

Two ceramic type LC connectors with clip

Fiber Optic Cabling – Ethernet Switch to

ZCP270 (Continued)

FIBER OPTIC CABLE

Cable Material

Multi-mode fiber (MMF) 62.5/125 µm plenum

Cable Lengths

3 m (9.9 ft), 15 m (49.5 ft), 50 m (165 ft)

greater than 50 m – user supplied

Maximum Length

2 km (6.560 ft) from the Ethernet switch to

the ZCP270.

Fiber Optic Cabling – Splitter/Combiner to

ZCP270

CONNECTORS

Two ceramic type LC connectors with clip on

each end

FIBER OPTIC CABLE

Cable Material

Multi-mode fiber (MMF) 62.5/125 µm

Cable Lengths

0.5 m (1.6 ft), 1.0 m (3.3ft), 3.0 m (9.9 ft),

15 m (49.5 ft), 50 m (165 ft)

greater than 50 m – user supplied

Maximum Length

2 km (6.560 ft) total from the Ethernet switch

to the ZCP270. including the cabling to the

splitter/combiner.

.png)

.png)