A-BSLC 500 EtherNet/IP Adapter

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

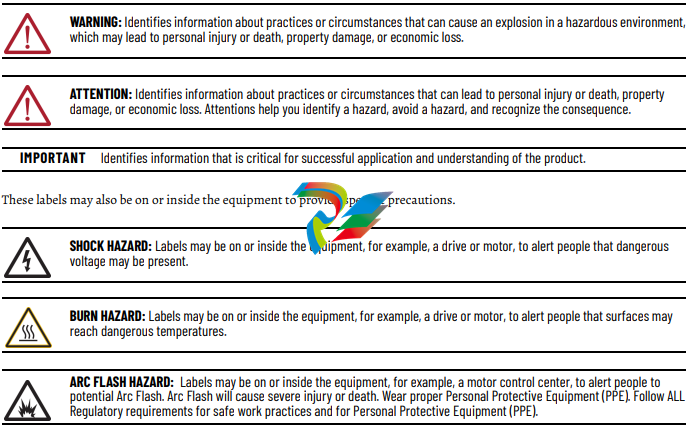

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

Overview

This chapter provides an introduction to the features and functionalities of the

1747-AENTR SLC™ 500 EtherNet/IP Adapter. It includes the following sections.

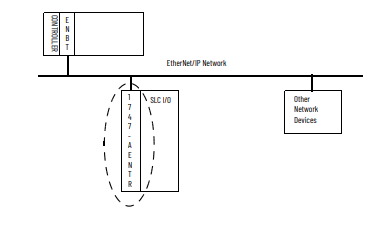

Module Description The 1747-AENTR Adapter enables CompactLogix™ and ControlLogix®

processors to control SLC™ I/O modules. It is primarily designed to enable

migration of existing SLC controlled systems to Logix-based systems.

The adapter mainly acts as a gateway between the SLC backplane and

EtherNet/IP and typically replaces an SLC controller in the 1746 rack. On

remote SLC racks, it replaces the 1747-ASB module or the ControlNet® adapters

1747-ACN15 and 1747-ACNR15.

Control of the backplane I/O is accomplished with a CompactLogix or

ControlLogix controller communicating through an EtherNet/IP router in the

Logix backplane, across EtherNet/IP, and into the 1747-AENTR gateway.

As a gateway between the SLC backplane and EtherNet/IP, the 1747-AENTR

module is a CIP™ server (for both Explicit Messaging and I/O) on the Ethernet

port, and an SLC host on the 1746 backplane.

Connections can be made to support 1746 and 1747 analog, digital, and

specialty I/O modules installed in the backplane.

For the complete list of supported I/O modules, see the table, List of I/O

Modules Supported by the 1747-AENTR Adapter on page 27.

Topic Page

Module Description 9

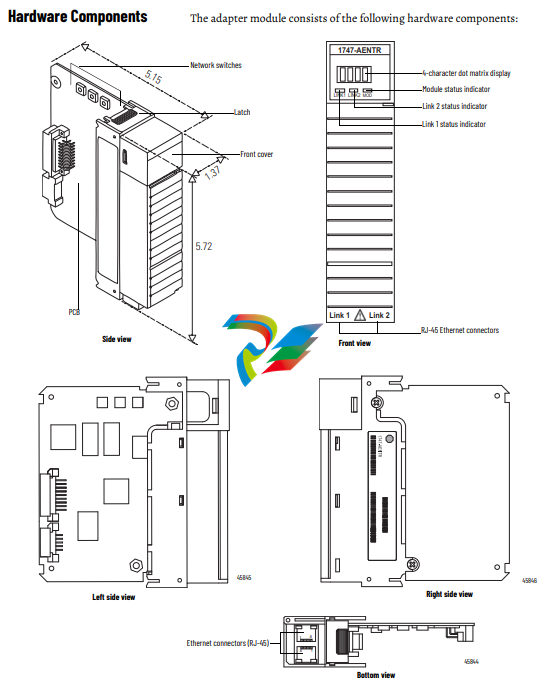

Hardware Components 10

The 1747-AENTR in a Logix System 11

Hardware/Software Compatibility 11

Diagnostic Indicators 11

What the Adapter Does 11

Use of the Common Industrial Protocol (CIP) 12

Understand the Producer/Consumer Model 12

Support of Direct Connections 12

IMPORTANT Studio 5000 Logix Designer® application (previously RSLogix 5000®)

revision 21 and later, and firmware revision 2.001 and later supports:

• multiple chassis, with a maximum number of three chassis;

• a maximum of 30 SLC I/O modules;

• a maximum of 96 Class 1 connections;

• up to 8 Class 3 connections.

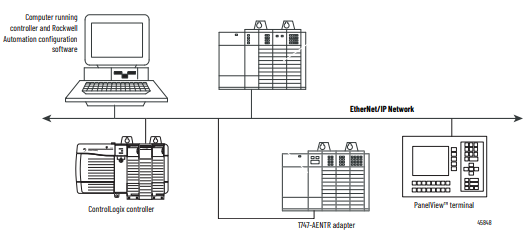

The 1747-AENTR in a

Logix System

In this example, the I/O modules communicate with the controller through the

1747-AENTR adapter. The controller can produce and consume tags to the I/O.

Configuration of devices and the network is done through the personal

computer running the controller and configuration software

Hardware/Software

Compatibility

The adapter and the applications described in this manual is compatible with

the following firmware revisions and software releases

roduct Firmware Revision/

Software Versions

1747-AENTR 1.001 or later

Logix controller v20 or later

RSLogix 5000 or Logix Designer v20 or later

RSLinx® software v2.59 or later

Diagnostic Indicators The module has the following diagnostic indicators:

• Link 1 and Link 2 status indicator

• Module indicator

• 4-character status display

What the Adapter Does The 1747-AENTR EtherNet/IP adapter performs the following primary tasks:

• Control of real-time I/O data (also known as implicit messaging) – the

adapter serves as a bridge between I/O modules and the network

• Support of messaging data for configuration and programming

information (also known as explicit messaging)

Use of the Common

Industrial Protocol (CIP)

The adapter uses the Common Industrial Protocol (CIP), the application layer

protocol specified for EtherNet/IP, the Ethernet Industrial Protocol. It is a

message-based protocol that implements a relative path to send a message

from the producing device in a system to the consuming devices.

The producing device contains the path information that steers the message

along the proper route to reach its consumers. Since the producing device

holds this information, other devices along the path simply pass this

information; they do not store it.

This has the following significant benefits:

• You do not need to configure routing tables in the bridging modules,

which greatly simplifies maintenance and module replacement.

• You maintain full control over the route taken by each message, which

enables you to select alternative paths for the same end device.

Understand the Producer/

Consumer Model

The CIP producer and consumer networking model replaces the old source

and destination (master and slave) model. The producer and consumer model

reduces network traffic and increases speed of transmission. In traditional I/O

systems, controllers poll input modules to obtain their input status. In the CIP

system, input modules are not polled by a controller. Instead, they produce

(multicast or unicast) their data periodically or at a cyclic rate.

Unicast is the default for version 20 with multicast as a selectable option. The

frequency of update depends upon the options chosen during configuration

and where on the network the input module resides. The input module,

therefore, is a producer of input data, and the controller is a consumer of the

data.

The controller also produces data for other controllers to consume. The

produced and consumed data is accessible by multiple controllers and other

devices over the EtherNet/IP network. This data exchange conforms to the

producer and consumer model.

Support of Direct

Connections

The EtherNet/IP adapter only supports direct connections. A direct connection

is a real-time data transfer link between a Logix controller and a 1746/1747 I/O

module through the 1747-AENTR adapter. Direct I/O connections occur at a

cyclic rate specified by the RPI during configuration

Install Your Adapter

This chapter describes how to install the 1747-AENTR adapter and connect it to

the EtherNet/IP network.

The following table lists where to find specific information.

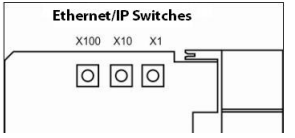

Set the Network Address

Switches

The network address switches are set to 999 and DHCP enabled, by default.

You can set the network Internet Protocol (IP) address in the following ways:

• Use the network address switches on the module.

• Use a Dynamic Host Configuration Protocol (DHCP) server, such as

Rockwell Automation BootP/DHCP.

• Retrieve the IP address from nonvolatile memory.

The adapter reads the network address switches first to determine if the

switches are set to a valid number. You set the node address by using the

network address switches. Valid settings range from 001…254.

When the switches are set to a valid number, the adapter’s IP address is

192.168.1.xxx (where xxx represents the number set on the switches).

The adapter’s subnet mask is 255.255.255.0 and the gateway address is set to

0.0.0.0. The adapter does not have a host name assigned, or use any Domain

Name System when using the network address switch settings.

If the switches are set to an invalid number (for example, 000 or a value greater

than 254 excluding 888), the adapter checks to see if DHCP is enabled. Setting

the switches to 888 restores default factory settings.

Topic Page

Set the Network Address Switches 15

Determine Power Requirements 18

Install the Adapter Module in the Chassis 18

Connect Your Adapter to the Ethernet/IP Network through RJ-45 Connection 19

Chapter Summary 2

Enable Web Server in Static IP mode

1. Set the switches to 000 and cycle power to the adapter.

The module LED flashes red and the four-character status display scrolls

the message “Web Server Enabled”.

2. Set the switches to the desired IP address and cycle power to the adapter.

3. In your web browser, enter the IP address of the adapter.

The web server home page displays.

Disable Web Server in Static IP mode

1. Set the switches to 901 and cycle power to the adapter.

The module LED flashes red and the four-character status display scrolls

the message “Web Server Disabled”.

2. Set the switches to the desired IP address and cycle power to the adapter.

3. In your web browser, enter the IP address of the adapter.

The web server home page does not display.

Enable Web Server in DHCP mode

Before you begin, verify that you have an active DHCP server on your network.

1. Set the switches to 000 and cycle power to the adapter.

The module LED flashes red and the four-character status display scrolls

the message “Web Server Enabled”.

2. Set the switches to 999 and cycle power to the adapter.

3. In RSLinx software, check the IP address that was assigned to the

adapter by the DHCP server and verify the connection.

4. In your web browser, enter the IP address of the adapter.

The web server home page displays.

Disable Web Server in DHCP mode

Before you begin, verify that you have an active DHCP server on your network.

1. Set the switches to 901 and cycle power to the adapter.

The module LED flashes red and the four-character status display scrolls

the message “Web Server Disabled”.

2. Set the switches to 999 and cycle power to the adapter.

3. In RSLinx software, check the IP address that was assigned to the

adapter by the DHCP server and verify the connection.

4. In your web browser, enter the IP address of the adapter.

The web server home page does not display.

Enable Web Server in User-set IP mode

1. Set the switches to 000 and cycle power to the adapter.

The module LED flashes red and the four-character status display scrolls

the message “Web Server Enabled”.

2. Set the switches to 999 and cycle power to the adapter.

3. In RSLinx software, change the Port Configuration setting to “Manual

IP”, set the desired IP address, and cycle power to the adapter.

4. In your web browser, enter the IP address of the adapter.

The web server home page displays.

Disable Web Server in User-set IP mode

1. Set the switches to 901 and cycle power to the adapter.

The module LED flashes red and the four-character status display scrolls

the message “Web Server Disabled”.

2. Set the switches to 999 and cycle power to the adapter.

3. In RSLinx software, change the Port Configuration setting to “Manual

IP”, set the desired IP address, and cycle power to the adapter.

4. In your web browser, enter the IP address of the adapter.

The web server home page does not display.

Determine Power

Requirements

The Ethernet adapter requires 5V DC with current consumption of 470 mA.

The power is supplied through backplane from SLC power supply. Remember

to consider this requirement when planning your system configuration.

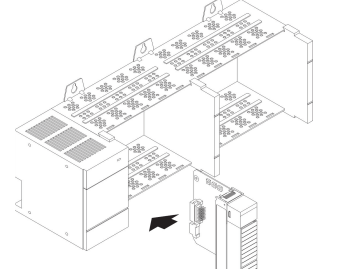

Install the Adapter Module

in the Chassis

After you set the appropriate switch assemblies for your adapter module,

follow these procedures for installation.

See the Industrial Controller Wiring and Grounding Guidelines publication

1770-4.1 for proper grounding and wiring methods to use when installing your

module.

1. Remove power from the I/O chassis before inserting (or removing) the

module.

2. Align the circuit board with the chassis card guide in the left slot.

. Install the module in slot 0 of the chassis by aligning the circuit board

with the chassis card guide.

The 1747-AENTR module must be installed only in slot 0 (leftmost slot)of

the chassis.

Press firmly and evenly to seat the module in its backplane connectors.

To remove the module, press the releases at the top and bottom of the

module and pull it out.

ATTENTION: Do not force the module into the backplane connector. If you

cannot seat the module with firm pressure, check the alignment. Forcing the

module can damage the backplane connector or the module.

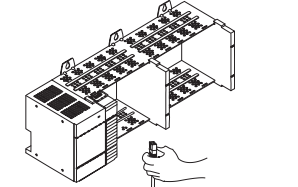

Connect Your Adapter to the Ethernet/IP Network through RJ-45 Connection Connect your 1747-AENTR adapter module to an Ethernet/IP network as shown in the following example: Wire the RJ-45 connectors as shown. To connect the module to the network, follow these steps: 1. Attach the cables with the RJ-45 connectors to the two Ethernet ports on the bottom of the module. ATTENTION: Do not force the module into the backplane connector. If you cannot seat the module with firm pressure, check the alignment. Forcing the module can damage the backplane connector or the module. WARNING: If you connect or disconnect the communication cable with power applied to this module or any device on the network, an electrical arc can occur. This could cause an explosion in hazardous location installations. Be sure that power is removed or the area is nonhazardous before proceeding. 1 8 8 1 Signal 1 TxData+ 2 TxData3 Recv Data+ 4 Reserved 5 Reserved 6 Recv Data7 Reserved 8 Reserv

• Module Settings

- Switches

• SLC Backplane Statistics

- I/O Errors

- I/O Scans Completed

- Maximum Scan Time

- Average Scan Time

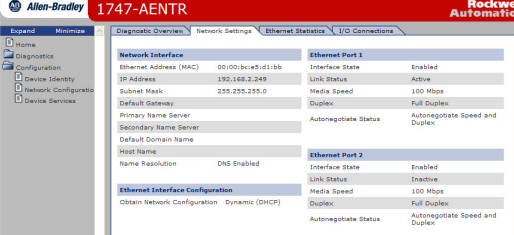

Use the Network Settings Page

To use the Network Settings page for network related information, follow this

procedure.

1. Click Network Settings tab at the top of the page or panel on the left.

This opens the Network Settings page.

2. From the Network Settings page, you can view the following: • Network Interface - Ethernet Address (MAC) - IP Address - Subnet Mask - Default Gateway - Primary Name Server - Secondary Name Server - Default Domain Name - Host Name - Name Resolution • Ethernet Interface Configuration - How the Network Configuration was obtained - Static or Dynamic

• Ethernet Port 1 and 2

- Interface State

- Link Status

- Media Speed

- Duplex

- Autonegotiate Status

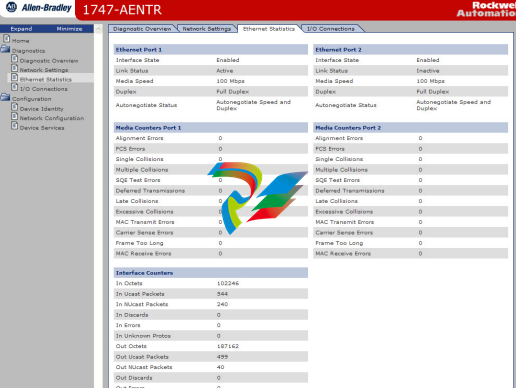

Use the Ethernet Statistics Page

To use the Ethernet Statistics page for information about the Ethernet link and

interface and media counters, use this procedure.

1. Click Ethernet Statistics tab at the top of the page or from the panel on

the left.

The Ethernet Statistics page open

From the Ethernet Statistics page, you can view the following:

• Ethernet Port 1 and Port 2

- Interface State

- Link Status

- Media Speed

- Duplex

- Autonegotiate Status

.png)

.png)

.png)