ALSTOM Ethernet Manual

Preface

This document

The Ethernet Manual is the same for all ALSTOM Power Service controllers equipped with Ethernet. Therefore reference to specific controller names such as EPIC or EFFIC will not be used from this point, instead the general term “controller” will be used. This Ethernet Manual contains information for the Designing Engineers on the pre-commissioning of the Ethernet network. It also contains information for Shift Operators on the PC-MTU software, which is a software used for setting up, operating and monitoring an installation of several controllers in the network. The PC-MTU software is linked together with the web pages on the controllers built-in web server. These web pages are the interface used to configure each individual controller. For more information, see Operator’s & Installation Manual.

Related documents

The following documents are related to the Ethernet Manual:

• Ethernet Manual- (this document).

• EPIC/EFFIC Operator’s & Installation Manual - contains information for all groups of users from the installation and commissioning to daily operation and tuning of the cleaning process. -Shift Supervisor Advanced operation and taking action on all alarms that may occur. -Process Engineer From small to medium scale diversions from factory settings in order to optimize the cleaning process. -Commissioning Engineer All stages of the commissioning. -Installation personnel (mechanical and electrical) Mechanical, electrical and communication installation.

ALSTOM Power Service reserves the right to revise any publication and to make changes to its contents, at any time, without obligation to notify any person or entity of such revision or changes. Furthermore, ALSTOM Power Service reserves the right to make changes to any and all parts of hardware and software, at any time, without obligation to notify any person or entity of such changes.

Ethernet standard

Ethernet is a network standard of communication. The most widely used for LAN communication, Ethernet typically runs at 100 megabytes per second. All new controllers developed by ALSTOM Power Service use the Ethernet standard for communication. The following chapter describes what type of equipment is needed to successfully set up a Ethernet network that functions well together with Alstom Power Service products.

General information on Ethernet

For general information on Ethernet there is a lot of information available both on the Internet and in published books. A good place to start is one of the following websites:

• Cisco Internetworking Technology Overview for Ethernet

• Howstuffworks http://computer.howstuffworks.com/ethernet.htm For specific information on Industrial Ethernet standards the Industrial Ethernet Planning and Installation Guide is recommended, can be down loaded from the following website

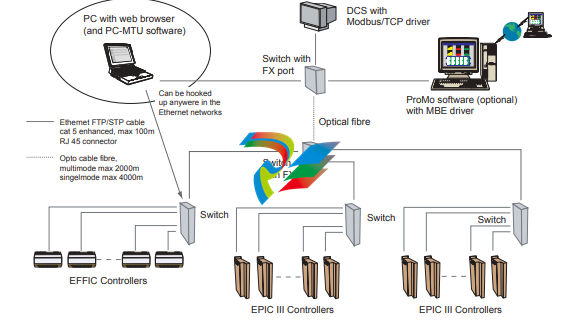

Typical Ethernet network

Ethernet switch

The Ethernet switch shall meet the following standards:

• EMC immunity for industry EN 50082-2 or EN 61000-6-2 Alstom Power Service has successfully used the switches from HMS Industrial Networks, Sweden and different types of switches from Hirschman Electronics.

Ethernet hub

Ethernet hub should not be used in a new installation, because it will decrease the performance of the network. With a hub in the network it is also more difficult to calculate the allowed cable lengths.

Connection to controller

The Ethernet board connection on the controller is of the following type:

• RJ45 10/100M/bit auto negotiation

Cables

Cat 5E FTP cables with RJ45 connectors are recommended for the Ethernet network.

Ethernet ports and protocols

The following Ethernet ports are used:

• Port 20, 21 for FTP • Port 80 for HTTP

• Port 502 for Modbus/TCP data

• Port 3 250 for PC-MTU - IP config

• Port 49 200, 49 201 for the master functionality and PC-MTU.

Ethernet routers

Routers should not be installed in the EPIC III Ethernet network. The PCMTU and master functionality will not function properly through it.Setup Ethernet network

The following chapter describes how to install the software and how to setup your Ethernet network. The installation procedure is the same for all ALSTOM Power Service controllers equipped with Ethernet. Therefore reference to specific controller names such as EPIC or EFFIC will not b

Software installation

1. Insert the PC-MTU software CD into your CD-ROM drive. 2. Follow the installation instructions.

System requirements

System requirements

• PC with 300 megahertz or higher processor clock speed recommended.

• Intel Pentium/Celeron family, or AMD K6/Athlon/Duron family, or compatible processor recommended.

• 128 megabytes (MB) of RAM or higher recommended.

• Super VGA (1024 x 768) or higher-resolution video adapter and monitor. • CD-ROM or DVD drive.

• Keyboard and Microsoft Mouse or compatible pointing device.

• Microsoft Windows® 2000 or Microsoft Windows XP®

• Microsoft Internet Explorer® 6.0 or higher.

.png)

.png)