FOXBORO Compact FBM240. Redundant with Readback, Discrete

Compact FBM240. Redundant with Readback, Discrete

Output and Discrete Input Module

Overview

The Compact FBM240is an 8 channel input and 8 channel output Foxboro™ DCS

Fieldbus Module (FBM) available as a single or redundant module. A redundant pair

of the modules combine to provide redundancy at the FBM level, with field I/O wired to

one commontermination assembly (see Figure 1). Each module independently holds

the output(s) at its specified output value(s), and each independently reads back its

observed value of the output.

This module is part of the Compact 200 Series I/O subsystem described in Compact

200 Series I/O Subsystem Overview (PSS 41H-2COV).

Aredundant contact output block in the control software validates each output in

conjunction with information to/from the module.

Features

• Eight discrete outputs/Eight discrete voltage monitor inputs

• Eight discrete inputs read back the voltage across the relay contacts. Sets the

channel BAD if the state of the contact disagrees with the state of the

corresponding output channel

• Monitors each FBMoutput and sets the output channel BAD if the output is in the

wrong state

• Single or redundant module

• Termination Assemblies (TAs) for locally or remotely connecting field wiring to the

Compact FBM240

• Supports discrete relay outputs capable of switching:

◦ 10Aat80to120VAC,or

◦ 5Aat80to125VDC,or

◦ 5Aat15to30VDC,or

◦ 5Aat80to120VAC

• Supports channel-isolated discrete I/O:

◦ 15-60VDC@2A,fusedoutputs

◦ 15-60VDCinputs

NOTE: Support for this termination assembly and the new Fail-Safe

configuration options described in Fail-Safe, page 6 require version 1.40N or

later firmware.

• Redundantoperation failure detection

◦ Outputcontact monitor readback and high coverage of internal FBM detected

failures allows redundant partner to automatically continue to drive discrete

outputs and to monitor inputs

• Internal per channel output demand state failure detection

◦ OutputChannel is marked BAD in both Single and Redundant Operation if the

demand state read-back indicates a state of miss-compare

Internal Readback of Output

The Compact FBM240has8internal readback channels, one per each output

channel, used to verify that the output has changed to the requested state. These

channels read the voltage across the relay contacts on the relay termination

assemblies. The states of these channels are displayed on LEDs on the front panel of

the Compact FBM240. When external power is applied to the relay contact of each

channel, the LED for that channel is ON when the relay contact is CLOSED, and OFF

when the relay contact is OPEN. If the state of the contact disagrees with the state of

the corresponding output channel, the channel is marked BAD.

The FBMalso monitors each of its eight outputs and sets the corresponding output

channel BAD if the output is in the wrong state.

If the channel or input power is marked BAD, the CP presents that information to the

Foxboro DCS for display as a System Management alarm and as a control block

alarm

Redundant Outputs

Aredundant contact output function block, COUTR, is used for each redundant pair of

outputs. The COUTR block handles output writes and initialization logic for the

redundant channels. On each write of the COUTR block, identical output writes are

sent to both modules, fully exercising the Fieldbus and the logic circuitry of each

module. You can select a sustained output that follows the block input or a pulsed

output with a selectable pulse width.

Whenafailure is detected in one of the modules, its output is marked BAD and the

corresponding channel in the good module automatically continues to drive the

discrete outputs.

Each output channel drives an externally powered load. Power for each Compact

FBM240module is diode OR’d together in the redundant adapter to help assure

redundant power. The microprocessor of each module executes the digital output

application program, plus diagnostic routines that validate the health of the FBM.

Fail-Safe

Configurable options for output safety include:

• Digital Output Fail-Safe Fallback Data- specifies the channel fallback value (0 or

1) for each of the eight digital outputs

• Maskoption- determines which of the eight digital outputs hold its current value

and which outputs assume the fallback values

• Fieldbus Fail-Safe Delay Time- length of time the FBM waits for a communication

from the CP before entering a communications fail

Redundant Modules

For redundant modules, the Fail-Safe Fallback Data and mask options are

configurable. An additional option is provided so that the module data will fall back to

zero (0) when the module is put off-line for maintenance functions so that it will not

interfere with the remaining module which is still on-line.

The Compact FBM240requires version 1.40N or later firmware to support this feature.

Single Modules

For single modules, the Fail-Safe Fallback Data and Mask options are configurable.

Compact Design

The Compact FBM240’s design is narrower than the standard 200 Series FBMs. It

has a rugged Acrylonitrile Butadiene Styrene (ABS) exterior for physical protection of

the circuits. Enclosures specially designed for mounting the FBMs provide various

levels of environmental protection, up to G3 harsh environments, per ISA Standard

S71.04.

High Reliability

The redundancy of the module pair, coupled with the high coverage of detected faults,

provides a very high subsystem availability time.

The module performs signal conversion required to interface electrical input signals

from field sensors to the optionally redundant Fieldbus. It executes the Discrete I/O

program with the following configurable options: Input Filter Time, Fail-Safe

Configuration, and Sustained or Momentary Outputs. If the Momentary Output

configuration is selected, then Pulse Output Interval is also configurable.

Whenredundant, either module may be replaced without upsetting field input or

output signals to the good module. The module can be removed/replaced without

removing field device termination cabling, power, or communications cabling

Easy Removal/Replacement

The module mounts on a Compact 200 Series baseplate. Two screws on the FBM

help secure the module to the baseplate.

Redundant modules must be located in adjacent positions on the baseplate, with the

first module located in an odd-numbered position (for example, the positions labelled

“3” and “4”). To achieve redundancy, a redundant adapter module is placed on the two

adjacent baseplate termination cable connectors to provide termination for a single

cable (see Figure 1). A single termination cable connects from the redundant adapter

to the associated termination assembly (TA).

Whenredundant, either module may be replaced without upsetting field input signals

to the good module. Each module can be removed/replaced without removing field

termination cabling, power, or communications cabling.

Modular Baseplate Mounting

The Compact FBM240module mounts on a DINrail mounted Modular Baseplate,

which accommodates up to four or eight FBMs. The Modular Baseplate is either DIN

rail mounted or rack mounted, and includes signal connectors for the redundant

Module Fieldbus, redundant independent DC power, and termination cables.

Redundant modules must be located in odd and even adjacent positions on the

baseplate (positions 1 and 2. 3 and 4. 5 and 6. or 7 and 8). To achieve the

redundancy, a redundant adapter module is placed on the two adjacent baseplate

termination cable connectors to provide a single termination cable connection (See

Figure 1. page 3).

To system configurator applications and to other systems monitoring through SMON,

Foxboro DCS System Manager, and SMDH, redundant FBM240s appear to be

separate, nonredundant modules. The functional redundancy for these modules is

provided by their associated control blocks.

Redundant Modules in Foxboro DCS HMI

The redundant pair of modules appear as two independent modules to system

management software applications (such as Foxboro DCS System Manager and

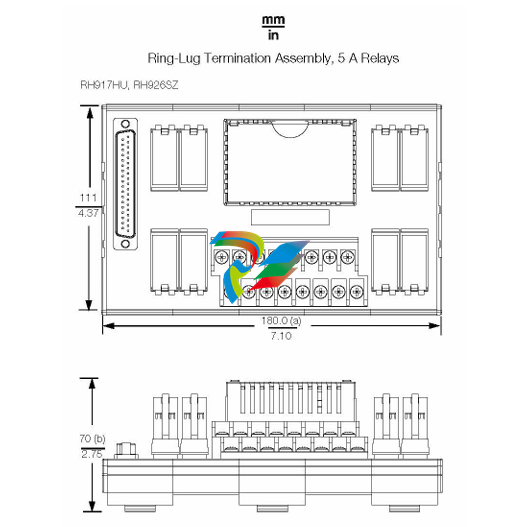

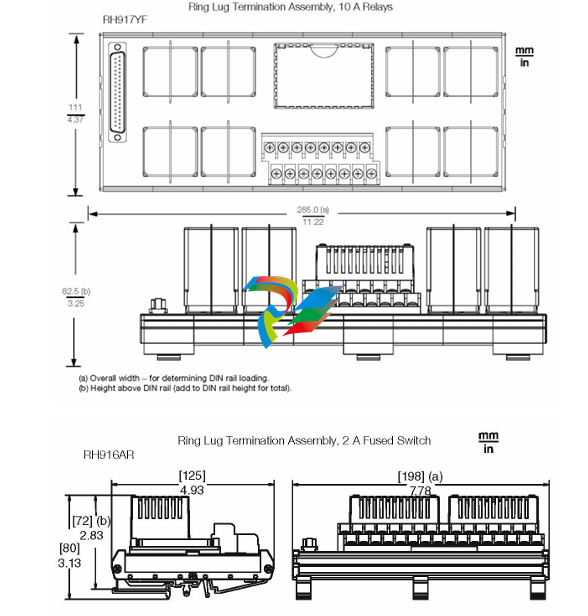

Termination Assemblies

Field I/O signals connect to the FBM subsystem via DIN rail mounted termination

assemblies (TAs). The TAs used with the Compact FBM240 provide:

• Outputsignal connection points

• External power connection point

• 5Aunsealedrelay or a 10 Aunsealed relay for each output

• 15-60VDCswitch andvoltage monitor inputs

The relay TAs have a high voltage input circuit that monitors the voltage across the

contacts of each output relay. Monitor circuits are located on daughter card

assemblies mounted on the TAs. There are two daughter cards per TA, each with four

monitor circuits. The TAs are:

• RH917YF-80to125VDCat5Aor80to120VACat10A

• RH917HU-80to120VACat5A

• RH926SZ-15to30VDCat5A

• RH916AQ/RH916AR-15to60VDCvoltagemonitor and 2 Aswitch

NOTE: WhentheCompact FBM240output opens, the TA contacts still apply

current to the circuit due to the TA’s readback circuitry, as described in Table 2 and

Table 3.

The RH916AQ/ARpassive TA provides fused 2 A outputs and independent inputs for

use with 15-60 VDC.

The redundant adapter connects the redundant FBM’s baseplate connectors together.

The redundant adapter provides a single termination connection to a single TA.

The DIN rail mounted termination assemblies connect to the redundant adapter by

means of a removable termination cable. The cable is available in a variety of lengths,

up to 30 meters (98 feet), allowing the termination assemblies to be mounted as

needed by plant design.

Visual Indicators

Red andgreen light-emitting diodes (LEDs) incorporated into the front of the modules

provide visual status indications of FBM functions, as well as the discrete states of the

individual output points.

.png)

.png)