EMERSONOvation™ VHF Power Delivery System Leading power technology to enable advanced dielectric etch and PVD processes

Benefits

Broadens process windows

Expands process capabilities

Improves plasma characteristics

Increases etch rate, selectivity,

and uniformity

Reduces CoO

The Ovation™ fully integrated, VHF power delivery system enables faster, higher

precision for demanding narrow-linewidth dielectric etch processes. It is the first to

accurately deliver power into a non-50-Ω environment without an external sensor,

reacting faster than traditional power supplies. The 60-MHz power delivery reduces

voltage potential across the plasma sheath, minimizing ion etch damage, and thus

improving film quality and yields. Its embedded measurement technology enables

previously unavailable insight into chamber plasma parameters and performance.

Features

2760 W, 60 MHz (contact factory

for higher power requirements)

Sweep frequency

Non-50 Ω measurement

capability

Analog, RS-232, and Ethernet

control options

Smaller footprint—half-rack

option for power up to 2.7 kW

Highly stable and reliable

Expert applications support

Improves Film

Quality and Yields

As process geometries continue to

shrink with decreasing metal widths

and line spaces, the Advanced Energy®

Ovation VHF power-delivery system

offers an innovative solution to help

you achieve desirable properties in sub90-nm dielectric etch, HDP-CVD, and

PECVD processes. Critical dimensions

and narrow linewidths require

stable and accurate power-delivery

systems with higher-than-traditional

frequencies. The unique technology

in the Ovation power-delivery system

allows you to optimize your processes

with enhanced VHF power delivery

and measurement. Further, 60-MHz

technology reduces voltage potential

across the plasma sheath, minimizing

ion etch damage and thus improving

film quality and yields.

Broadens Process

Windows

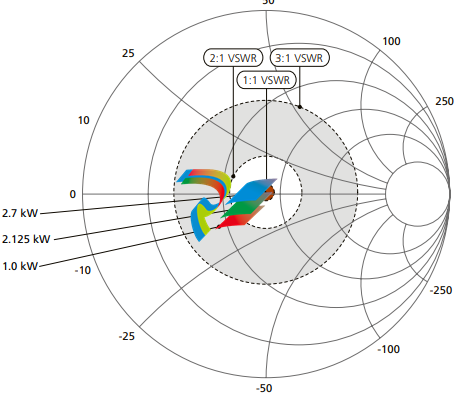

This advanced, very high frequency

power technology enables you to

expand your process window over

a wide VSWR load range with output

powers up to 4.5 kW at frequencies

of 60 MHz.

Developed to meet the demanding

requirements of advanced etch

processes, the Ovation VHF powerdelivery system accurately and

efficiently delivers the optimal power

required into a wide VSWR window,

up to 3:1. The system’s unique powerdelivery scheme offers the highest

power efficiency and power density

commercially available—in a compact,

half-rack unit—nearly half the size

of competing systems for power

requirements up to 2.7 kW.

Expands Process Capabilities

The Ovation system’s power platform ensures stable performance, reliable

operation, improved overall film characteristics, and increased yields—

even at the 65-nm range.

Expanded process capabilities include:

• Quick power system compensation for plasma load changes due

to process step transitions

• Accurate measurement and power delivery outside of 50 Ω

The Ovation power system is specifically designed to expand the tight process

windows constraining advanced etch processes by providing the capabilities

for users to drive higher plasma densities, with a wide operating range and

unmatched transient response.

Improves Plasma Characteristics

To avoid device damage, as smaller gate structures become the norm, processes

must run at lower-than-traditional voltages. High-frequency power systems readily

enable these low-voltage processes. Process developers who contend with these issues

have found that high-frequency systems provide such tangible benefits as:

• Increased plasma density for etch and CVD applications

• Reduced process-induced damage in etch applications

Higher Etch Selectivity

and Etch Rates

Today’s demanding, narrow-linewidth,

dielectric etch processes require rapid

power supply responses to transitions

between process steps. The Ovation

power-delivery solution ensures

consistent and repeatable performance.

Its VHF power-delivery system is the

first to accurately deliver power into a

non-50-Ω environment, allowing the

Ovation generator to react faster than

traditional power supplies.

This fully integrated power-delivery

system enables faster, higherprecision processes such as those

required for sub-90- and sub-65-

nm etch applications, through the

implementation of a unique powerdelivery scheme. This scheme results in:

• Higher etch rates

• Higher yields and film quality

on processes with precision control

between transition process steps

• More efficient power transfer

Enhanced Power

Measurement System

The Ovation power-delivery

solution features embedded advanced

measurement technology, including

internal impedance measurement.

A non-50-Ω measurement capability

facilitates previously unavailable

insights into chamber plasma

parameters and performance.

The system also offers embedded

power instrumentation for

real-time data mining

Optional Equipment

Compact and Versatile for

Any Process Environment

The Ovation system is compact

in size for easy installation and

seamless integration into your new

or existing processes. The small

product footprint maximizes your

chamber design flexibility.

Communication Options

This power-delivery system offers an

array of interfacing options, including

analog and RS-232 (AE Bus) interfaces.

RS-232 interfaces, when used with

the optional AE® Virtual Front Panel

(VFP) software package, allow data

visualization of many internal source

parameters and fault conditions.

Reliability & Compliance

The Ovation power-delivery

system has received the following

safety certifications:

• CE 73/23/EEC & 89/336/EEC

• IEC/EN 61010-1

• CSA C22.2 No. 1010.1

• ANSI/ISA-82.02.01

• NRTL/C

• SEMI F47

• EN 55011, EN61326, and 47 CFR

Value-Added Options

Virtual Front Panel

AE’s optional VFP graphical computer

interface gives you the ability to

perform critical functions dynamically,

and in real time, including:

• Process setup

• Troubleshooting

• Operational control

• Data visualization

Navigator™ Matching Network

Advanced Energy’s Navigator™

matching network provides advanced

match technology for rapid, accurate,

and reliable matching from an

RF generator to the processing

tool across a wide range of load

impedances. This versatile matching

network optimizes delivered power

to semiconductor, flat panel display,

and MEMs manufacturing processes,

including CVD, HDP-CVD, and

chamber clean applications. Equipped

with microprocessor-controlled

stepper motor circuitry and digital,

user-selectable tuning algorithms,

the Navigator matching network

minimizes reflected power by

automatically tuning the complex

impedance of a coupled plasma. The

network’s digital scheme delivers

superior performance over traditional

analog-based tuning methods, which

are less consistent and accurate. An

optional, internal Z’Scan® RF sensor

provides real-time measurement

and analysis of process power

and impedance, enabling process

engineers to identify and significantly

reduce process variability—a

competitive advantage over other

matching networks without real-time

monitoring capability. In addition, the

Navigator matching network features

embedded instrumentation that

permits process engineers to exercise a

level of electrostatic chuck control and

a level of process-recipe optimization

not possible with non-embedded,

separate instrumentation. Moreover,

with AE’s VFP software, process

engineers can monitor and command

the matching network through a

personal computer—enabling a level

of control not previously available.

Sweep Frequency

The Ovation 3060 sweep frequency

incorporates direct digital synthesis

(DDS) technology for control of

its operating frequency when the

power system is mismatched. This

field-proven, robust technology has

been incorporated into AE products

since 1996. The frequency can be

programmed to dither over a predetermined range, enable plasma

ignition, and minimize the mismatch

to the power system during plasma

processing. The DDS operating

parameters can be set via an RS232 or Ethernet port and are stored

indefinitely in non-volatile RAM.

General Specifications

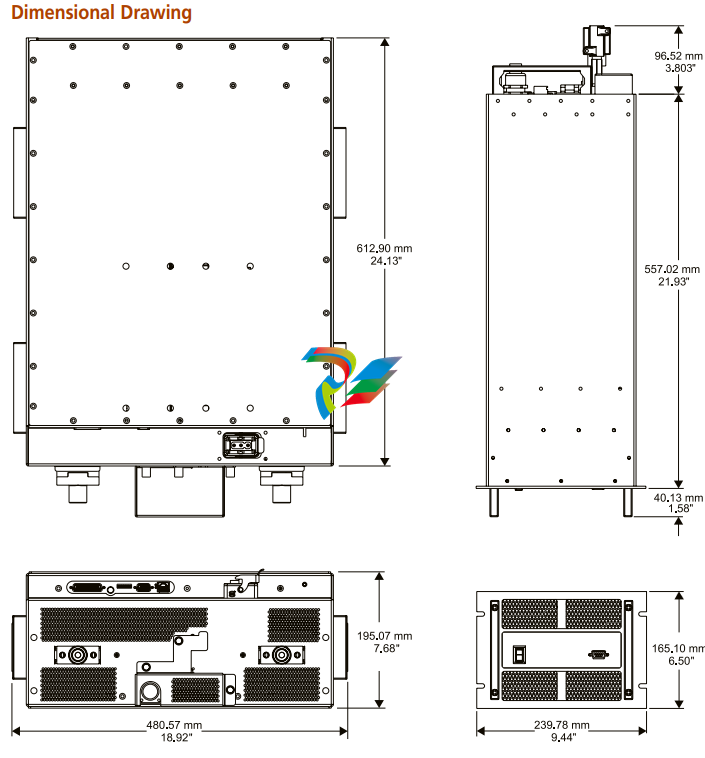

Physical

Size

Up to 2.7 kW 16.5 cm (H) x 24.0 cm (W) x 59.7 cm (D)

6.5" (H) x 9.45" (W) x 23.5" (D)

(Does not include connectors and handles)

Above 4.5 kW 19.5 cm (H) x 43.9 cm (W) x 64.4 cm (D)

7.68" (H) x 17.30"(W) x 25.35" (D)

(Does not include connectors and handles)

Weight < 29.5 kg (65 lb) max for power up to 2.7 kW

< 65.9 kg (145 lb) max for powers higher than 2.7 kW

RF Output Connector Type HN female at 2.7 kW/ QRM F for 4.5 kW

User Interface Connector 25-pin, sub-D, female

Remote Digital Interface

(AE Bus)

9-pin, sub-D, female

Electrical

Input Power

Line Voltage 180 to 229 VAC (208 V nominal), 3 Φ, 4-wire, no neutral connection required

Line Frequency 50/60 Hz

RF Output

Full-Rated Output Power 2.7 to 4.5 kW, depending on model

Accuracy +3% or 20 W, whichever is greater

Optional V and I Outputs Available for non-50-Ω power measurement

Frequency 60 MHz

.png)

.png)

.png)