EMERSONInformation and Control Systems Platform

Background

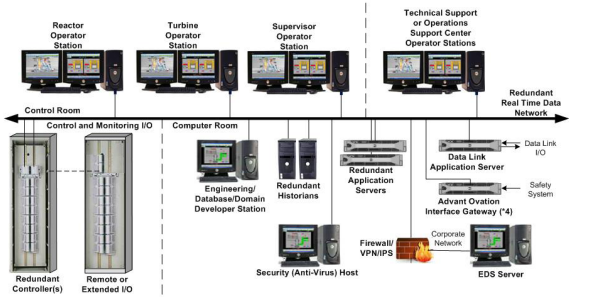

The Information and Control (I&C) Systems

Platform is a non-safety distributed computer

system for Category B and Category C

applications. The platform has been applied in

numerous nuclear retrofit projects, and is the

standard basis for non-safety related nuclear

I&C systems in Westinghouse new-build

projects worldwide.

The overall platform includes integral

resources for both control and plant computer

functions, thus eliminating the need for

these to be separate systems. The basic

architecture is flexible for use with small

stand-alone systems to full-scale plant

systems, expanding easily for future phased

system upgrades.

Description

Input/output Modules – Modular industrial grade

I/O requiring no special handling, user addressing or

configuration. Up to 128 modules per controller of analog,

discrete, digital bus and special turbine-related I/O is available,

including advanced fault diagnostics and channel isolation.

• Workstations – Operator/engineering workstations

(Windows® PC-based) feature high-resolution display of

control/monitoring graphics, diagnostics, trending, alarms

and plant-status information with easy-to-use engineering

and configuration tools. The engineering station contains

a fully embedded relational database management system

storing configuration, process-point information and control

algorithm information. System and point data (including

user-defined fields) can be imported via user-friendly database

tools (e.g. Access or Excel).

• Historian – Scalable mass storage and retrieval of process data,

alarms, sequence of events (SOE), logs and operator actions for

5,000 to 100,000 point values. Presentation capabilities include

data queries, historical trending and SOE Reports. A bundled

reporting package allows for scheduled and triggered reports

to operators, engineers and maintenance personnel.

• Connectivity Servers – Open system interfaces (ODBC,

NetDDE, OPC) provide innovative technology for securely

transporting real-time or historical process data directly to a

user desktop for critical analysis of plant performance data.

Data link interfaces to third-party devices and protocols such

as Modbus, Allen-Bradley, GE Mark V/VI, RTP I/O, Toshiba

and MHI are also supported.

Westinghouse has designed and engineered several

additional system components that complement and extend

the Ovation product line to provide monitoring and plant

computer functionality, enhanced security, and integration

of safety and non-safety platforms specifically for the

nuclear power industry.

• Application Server – Redundant application servers execute

complex calculations and monitoring from a robust Nuclear

Applications Programs (NAP) library and data link interfaces

with external plant systems. Standard, pre-tested function

blocks based on IEC 61499/61131 standards significantly lower

development and testing time. Custom sub-applications can

also be created.

• Cyber Security – Westinghouse is leading the cyber security

assessment and compliance activities in the industry in

conjunction with the new AP1000TM plants, advanced

boiling water reactor (ABWR) and existing plants worldwide.

Using cyber security assessments, communication-isolation

techniques, physical security, cyber-secure networks and

operating systems, and the Ovation product security,

Westinghouse’s cyber security team provides practical, cybersecure solutions.

• Advant Ovation Interface (AOI) – A Gateway server connects

each safety division data network to the non-safety real-time

data network, providing strict one-way flow of real-time safety

system data for display and control. Data flow is strictly one

way from the safety to the non-safety subsystem.

Combining the superior high-speed performance and

capacity of the widely used Ovation product line with broad

nuclear application experience and system integration

components, the Westinghouse I&C platform provides

a flexible and upgradeable system that addresses both

operating and new plant requirements

The platform is based on the Emerson Ovation®

product line and also integrates key components

developed by Westinghouse for nuclear I&C

applications. As a distributed process control,

information and data management system,

Ovation offers a powerful, flexible and opensystem architecture, supported with field-proven,

industry-standard hardware, software, networking

and communications components. The extended

components support plant computer, monitoring and

various system-interface applications to meet nuclear

industry requirements.

Benefits

The I&C system platform presents true open

computing, allowing users to achieve higher

plant availability, reliability, efficiency, safety and

environmental compliance.

Extensive system benefits are realized through the key

elements of the Ovation product.

• Network – A standards-compliant, fully redundant, highspeed Ethernet network using commercial hardware,

and copper or fiber cabling. Each originating drop

periodically broadcasts point value and status at the

appropriate frequency.

• Controller – Each fully redundant PC-based controller

interfaces to the I/O subsystem, performs data

acquisition, and executes simple or complex modulating

and sequential control strategies (up to 32,000 process

points per controller).

.png)

.png)