Key Features:

1) Advanced Monitoring Capabilities: The 3500/20-01-02-01 offers real-time monitoring of vibration, temperature, and other critical parameters to detect any abnormalities or potential issues before they escalate.

2) Dual Redundancy: With dual-redundant architecture, this model ensures continuous monitoring and protection even in the event of a failure in one channel.

3) Scalable System: The 3500/20-01-02-01 can be easily expanded to accommodate additional monitoring points, making it suitable for both small-scale and large-scale operations.

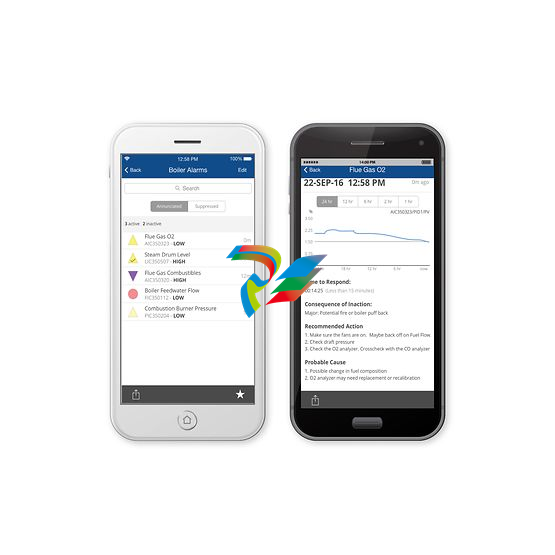

4) User-Friendly Interface: The system features an intuitive interface that allows for easy configuration, data analysis, and reporting.

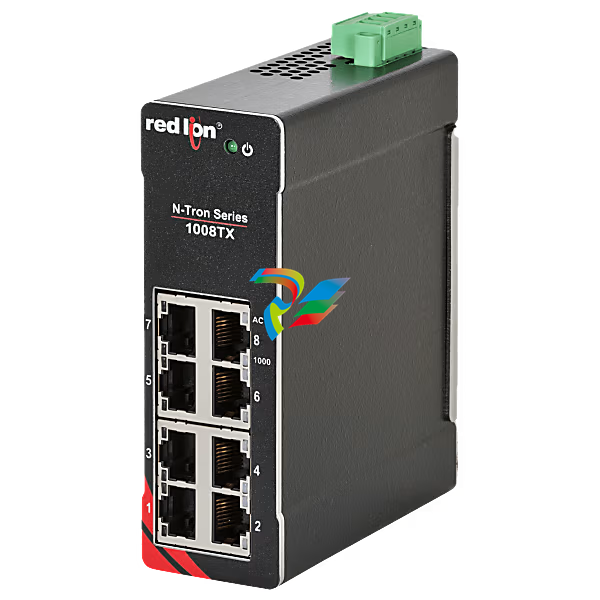

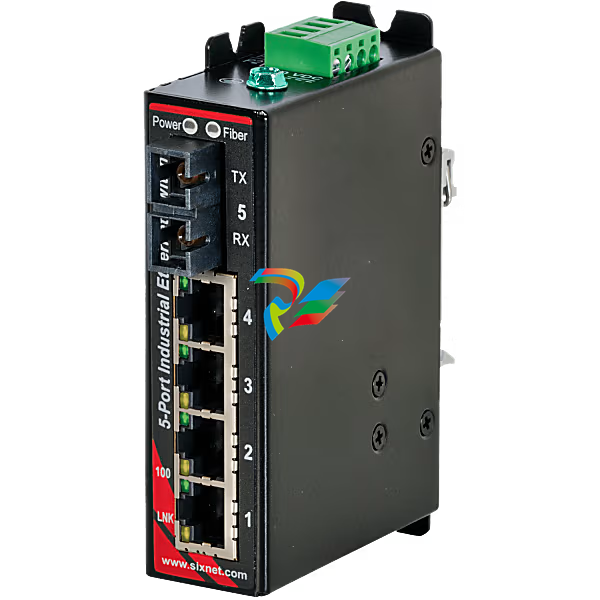

5) Remote Monitoring: Users can access real-time data and receive alerts remotely, enabling timely responses to any detected anomalies.

Typical Usage Scenarios:

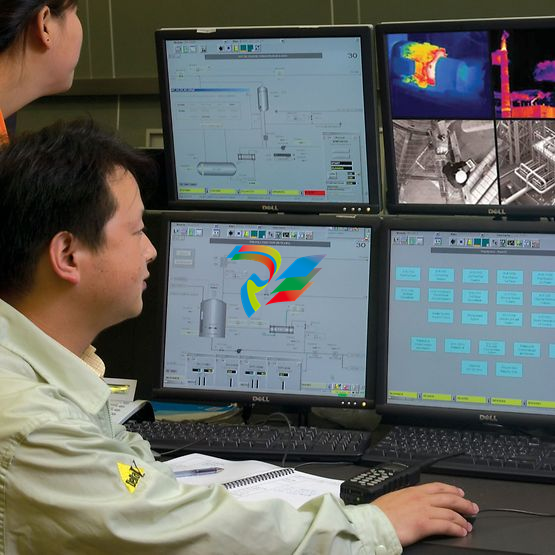

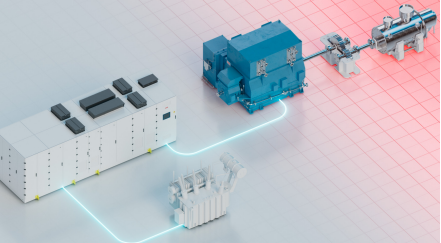

1) Power Industry: The 3500/20-01-02-01 is ideal for monitoring critical machinery in power plants, ensuring the continuous operation of turbines, generators, and other equipment.

2) Petrochemical Industry: In petrochemical facilities, this model can help prevent costly downtime by monitoring pumps, compressors, and other machinery for signs of wear or malfunction.

3) General Automation: For general automation applications, the 3500/20-01-02-01 provides essential protection for a wide range of equipment, from motors to conveyors.

Basic Advantages:

1) Increased Equipment Reliability: By continuously monitoring machinery health, the 3500/20-01-02-01 helps prevent unexpected failures and prolongs equipment lifespan.

2) Cost Savings: Early detection of issues allows for proactive maintenance, reducing downtime and repair costs.

3) Compliance: The system helps businesses meet regulatory requirements by ensuring the safety and reliability of their machinery.

Related Models:

1) Bently Nevada 3500/45-02

2) Bently Nevada 3500/92M

3) Bently Nevada 3500/60-01

4) Bently Nevada 3500/64M

5) Bently Nevada 3500/20-01-01-00

6) Bently Nevada 3500/62-01

7) Bently Nevada 3500/40M

8) Bently Nevada 3500/53-01

9) Bently Nevada 3500/44-02

10) Bently Nevada 3500/50-03

In conclusion, the Bently Nevada 3500/20-01-02-01 is a versatile and reliable machinery protection system that offers advanced monitoring capabilities, scalability, and user-friendly features. With its proven track record in various industries, this model is a valuable investment for businesses looking to maximize equipment reliability and performance.

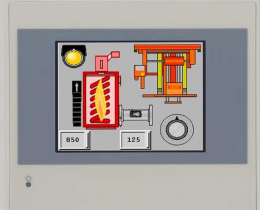

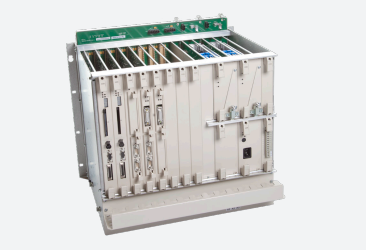

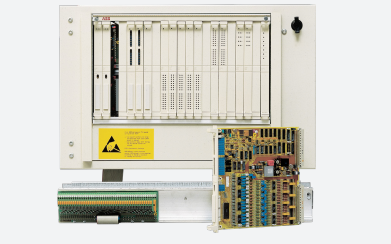

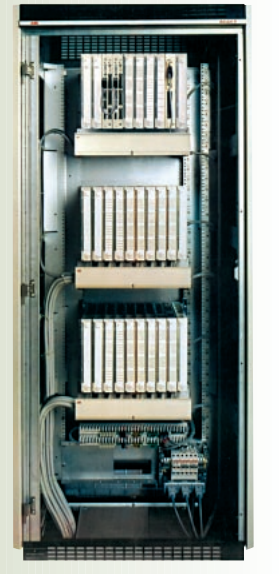

Bently Nevada 3500/20-01-02-01 - Display Module, Rack Interface

The Bently Nevada 3500/20-01-02-01 is a cutting-edge machinery protection and condition monitoring system designed for a variety of industries, including power, petrochemical, and general automation. This model comes from a reputable brand known for its reliable and high-quality products, making it a top choice for businesses looking to ensure the safety and efficiency of their equipment.

Key Features:

1) Advanced Monitoring Capabilities: The 3500/20-01-02-01 offers real-time monitoring of vibration, temperature, and other critical parameters to detect any abnormalities or potential issues before they escalate.

2) Dual Redundancy: With dual-redundant architecture, this model ensures continuous monitoring and protection even in the event of a failure in one channel.

3) Scalable System: The 3500/20-01-02-01 can be easily expanded to accommodate additional monitoring points, making it suitable for both small-scale and large-scale operations.

4) User-Friendly Interface: The system features an intuitive interface that allows for easy configuration, data analysis, and reporting.

5) Remote Monitoring: Users can access real-time data and receive alerts remotely, enabling timely responses to any detected anomalies.

Typical Usage Scenarios:

1) Power Industry: The 3500/20-01-02-01 is ideal for monitoring critical machinery in power plants, ensuring the continuous operation of turbines, generators, and other equipment.

2) Petrochemical Industry: In petrochemical facilities, this model can help prevent costly downtime by monitoring pumps, compressors, and other machinery for signs of wear or malfunction.

3) General Automation: For general automation applications, the 3500/20-01-02-01 provides essential protection for a wide range of equipment, from motors to conveyors.

Basic Advantages:

1) Increased Equipment Reliability: By continuously monitoring machinery health, the 3500/20-01-02-01 helps prevent unexpected failures and prolongs equipment lifespan.

2) Cost Savings: Early detection of issues allows for proactive maintenance, reducing downtime and repair costs.

3) Compliance: The system helps businesses meet regulatory requirements by ensuring the safety and reliability of their machinery.

Related Models:

1) Bently Nevada 3500/45-02

2) Bently Nevada 3500/92M

3) Bently Nevada 3500/60-01

4) Bently Nevada 3500/64M

5) Bently Nevada 3500/20-01-01-00

6) Bently Nevada 3500/62-01

7) Bently Nevada 3500/40M

8) Bently Nevada 3500/53-01

9) Bently Nevada 3500/44-02

10) Bently Nevada 3500/50-03

In conclusion, the Bently Nevada 3500/20-01-02-01 is a versatile and reliable machinery protection system that offers advanced monitoring capabilities, scalability, and user-friendly features. With its proven track record in various industries, this model is a valuable investment for businesses looking to maximize equipment reliability and performance.

The Bently Nevada 3500/20-01-02-01 is a cutting-edge machinery protection and condition monitoring system designed for a variety of industries, including power, petrochemical, and general automation. This model comes from a reputable brand known for its reliable and high-quality products, making it a top choice for businesses looking to ensure the safety and efficiency of their equipment.

Key Features:

1) Advanced Monitoring Capabilities: The 3500/20-01-02-01 offers real-time monitoring of vibration, temperature, and other critical parameters to detect any abnormalities or potential issues before they escalate.

2) Dual Redundancy: With dual-redundant architecture, this model ensures continuous monitoring and protection even in the event of a failure in one channel.

3) Scalable System: The 3500/20-01-02-01 can be easily expanded to accommodate additional monitoring points, making it suitable for both small-scale and large-scale operations.

4) User-Friendly Interface: The system features an intuitive interface that allows for easy configuration, data analysis, and reporting.

5) Remote Monitoring: Users can access real-time data and receive alerts remotely, enabling timely responses to any detected anomalies.

Typical Usage Scenarios:

1) Power Industry: The 3500/20-01-02-01 is ideal for monitoring critical machinery in power plants, ensuring the continuous operation of turbines, generators, and other equipment.

2) Petrochemical Industry: In petrochemical facilities, this model can help prevent costly downtime by monitoring pumps, compressors, and other machinery for signs of wear or malfunction.

3) General Automation: For general automation applications, the 3500/20-01-02-01 provides essential protection for a wide range of equipment, from motors to conveyors.

Basic Advantages:

1) Increased Equipment Reliability: By continuously monitoring machinery health, the 3500/20-01-02-01 helps prevent unexpected failures and prolongs equipment lifespan.

2) Cost Savings: Early detection of issues allows for proactive maintenance, reducing downtime and repair costs.

3) Compliance: The system helps businesses meet regulatory requirements by ensuring the safety and reliability of their machinery.

Related Models:

1) Bently Nevada 3500/45-02

2) Bently Nevada 3500/92M

3) Bently Nevada 3500/60-01

4) Bently Nevada 3500/64M

5) Bently Nevada 3500/20-01-01-00

6) Bently Nevada 3500/62-01

7) Bently Nevada 3500/40M

8) Bently Nevada 3500/53-01

9) Bently Nevada 3500/44-02

10) Bently Nevada 3500/50-03

In conclusion, the Bently Nevada 3500/20-01-02-01 is a versatile and reliable machinery protection system that offers advanced monitoring capabilities, scalability, and user-friendly features. With its proven track record in various industries, this model is a valuable investment for businesses looking to maximize equipment reliability and performance.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

![ABBCondition MonitoringMService V7.7 - User Manua MService V7.7 - User Manua [Document Type] ABB Ability™ Condition Monitoring for electrical systems - CMES User Manual MService Condition Monitoring V7.7 User Manual](https://aosspic10001.websiteonline.cn/hkw84666a/image/ABB.png)

.png)