GE350 Feeder Protection System

the following order:

A. Remove the 2 mounting screws near letters A and C, of label ABC (item#2), and

mount 2 standoffs.

B. Remove the 2 mounting screws near the letters B and E, of label ABCDE (item#3),

and mount 2 standoffs.

2. Place the IP20 cover (item#4) and secure it with 4 screws (item#5) using the suggested

tightening torque of 8lb-in.

NOTE

NOTE: Make sure the device terminals are wired before placing the cover. Use the 5 slots located

on each side of the cover to guide the wires outside of the cover.

Retrofit kit for IP20

Before attaching the cover, remove the old labels from the device (see item#2 and item#3)

and replace them with the new labels from the retrofit kit. Attach the cover as described in

the previous section.

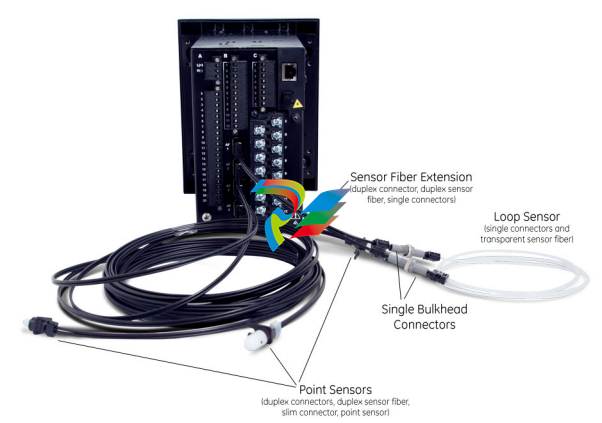

Arc flash sensors

Arc flash sensors house the fiber optics that are used to detect the arc flash. Mounting

details depend on the sensor type (point or loop).

For detailed installation, testing and maintenance guidance for Arc Flash sensors, see GET20057 3 Series Arc Flash Application Note.

If the relay is used in the computation for reducing the Hazard Reduction Category

code, operands for sensor failures must be assigned to an auxiliary output relay which

must be connected into the control logic of the breaker equipment to ensure safe

operations when the output relay is asserted. In the event of this assertion, the Hazard

Reduction Category code cannot be maintained unless backup protection is continuing

to maintain it.

CAUTION: This product uses optical electronic devices (line or point sensors) to sense arc flash

fault conditions. It is recommended to follow proper housekeeping measures &

establish a regularly scheduled preventive maintenance routine to ensure proper

device operation. For maintenance recommendations, see GET-20057 3 Series Arc

Flash Application Note

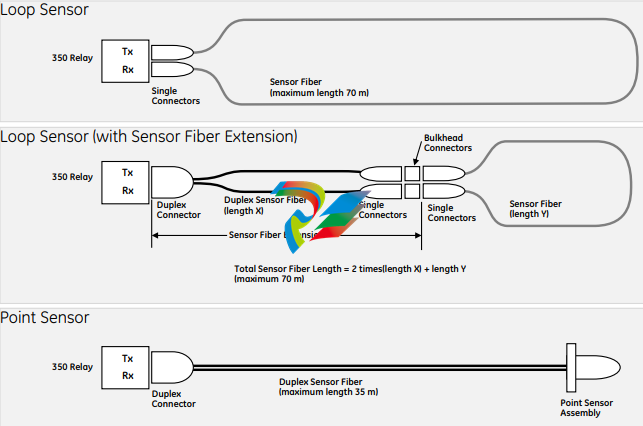

Arc flash sensors are available in two different configurations, point and loop. Loop sensors

can be used with a black-coated sensor fiber extension to connect the ends of the loop

sensor to the 350 relay through panels up to 51 mm (2 inches) thick.

Arc Flash sensor fiber is pressure sensitive and must be handled carefully to avoid

damage. Read the following guidelines fully before proceeding.

Care must be taken when handling the Arc Flash sensor fiber, which can be damaged if

twisted, bent, or clamped tightly during installation.

• Do not bend sensor fiber sharply, or with a radius of less than 35 mm (1.3 inches).

Sharp bends can damage the fiber. Do not pull or tug loops of sensor fiber, as sharp

bends may result.

• Do not clamp sensor fiber tightly during installation. Sensor fiber should be held in

place loosely for the best long-term performance. Avoid over-tightening ties which

may deform or break the sensor fiber.

• Do not pull or tug sensor fiber with force, as this may cause internal damage or

separate the fiber from the cable connector.

• Do not twist the sensor fiber, as twisting can damage the fiber resulting in

substandard performance.

• Do not attach sensor fiber directly to the bus or other live conductors.

• Avoid surface temperatures above 70 °C or 158 °F to prolong the life of the fiber.

• Secure all sensor fibers (loosely but securely) away from any moving parts.

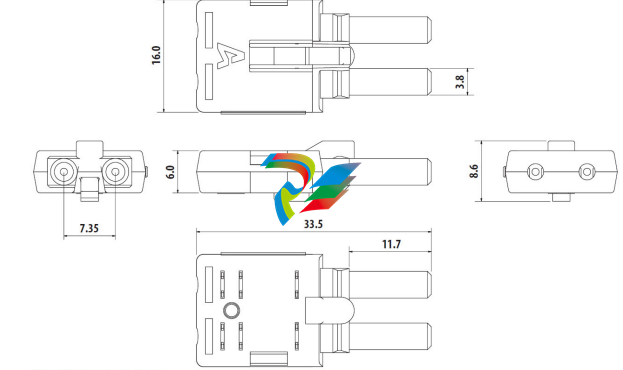

The point sensor fiber includes a duplex connector to connect to the back of the 350 relay

on one end, and a compressed slim connector that connects to the sensor itself on the

other end.

Before installing the AF sensor units, ensure that all other drilling and installation is

complete to minimize possible damage to the sensitive unit and connected sensor fiber

cable. Choose a location for the sensor clear of any obstructions that could shield the

sensor from arc flash light.

FASTPATH: Review the sensor fiber handling guidelines above.

Sensor fiber should be held in place loosely for the best long-term performance. Avoid

over-tightening ties which may deform or break the sensor fiber.

General installation:

1. Choose a location for the point sensor.

Arc flash point sensors should be installed clear of any obstructions that could shield

the sensor from arc flash light, and less than 2m (6ft 6") from any potential arc flash

source.

The sensor head should be pointed towards the most likely source of arc flash.

For further guidance selecting point sensor locations, see GET-20057 3 Series Arc

Flash Application Note.

2. Remove the slim connector from the point sensor assembly.

3. Carefully route the duplex sensor fiber from the point sensor location to the back of

the relay unit, minimizing loops and curves for the strongest possible signal. Ensure all

sensor fiber handling precautions are followed.

The slim connecter fits through holes with a diameter of 11 mm or greater, and can be

threaded through holes drilled in any panels between the relay and arc flash detection

location.

NOTE

NOTE: Install protective grommets when routing sensor fiber through metal walls.

4. Mount the point sensor using either a cable tie mount or through-hole mount, as

.png)

.png)

.png)