GE350 Feeder Protection System

detailed below.

5. Reconnect the slim connector to the point sensor.

Arc flash point sensors can be installed in one of two ways, using a cable tie mount or a

through-hole mount.

Cable tie mount:

• Requires a 2.5-mm-wide cable tie.

• Mount the sensor on a stick or similar using the cable tie, as shown in the following

figure.

Through-hole mount

• Requires a standard or self-tapping M3 screw, and optionally an M3 washer.

• Mount the sensor through a 10 mm hole made in the surface of any mechanical

structure inside the switchgear or on the surface of one side of the switchgear itself,

as shown in the following figure.

Make sure there is no dirt or dust inside the point sensor or on the surface because it

reduces the capturing efficiency of the device, increases its transmission loss, or both. If

the point sensor is covered with dust, clean it by blowing or wiping the dust off the point

sensor.

FASTPATH: The material of the point sensor is not affected by water-based cleaning agents, dish

soap, or organic solvents with an alcohol (ethanol) base. Do not use solvents or solvent

mixtures that contain acids because they can attack or dissolve the optical plastic

material.

Before installing the AF sensor units, ensure that all other drilling and installation is

complete to minimize possible damage to the sensitive unit and connected sensor fiber

cable.

FASTPATH: Review the sensor fiber handling guidelines above.

Sensor fiber should be held in place loosely for the best long-term performance. Avoid

over-tightening ties which may deform or break the sensor fiber.

FASTPATH: The loop sensor fiber can be connected directly to the 350 relay without a sensor fiber

extension, however, care must be taken to ensure correct alignment of the loop sensor

single connectors into the 350 light sensor input.

Installing the loop sensor fiber without an extension:

1. Plan the path of the loop sensor fiber, looping through the chamber or chambers

requiring arc flash detection. See GET-20057 3 Series Arc Flash Application Note for

detailed examples of loop sensor installation.

2. Ensure that both ends of the loop remain close together and can reach the 350 relay

light sensor inputs.

3. Install the loop sensor carefully, following all sensor fiber handling guidelines.

4. Plug the single connectors into the back of the 350 relay, ensuring correct alignment

as shown

Installing the loop sensor fiber with a sensor fiber extension:

1. Plan the path of the loop sensor fiber, looping through the chamber or chambers

requiring arc flash detection. See GET-20057 3 Series Arc Flash Application Note for

detailed examples of loop sensor installation.

2. Ensure that both ends of the loop remain close enough together to be reached by the

sensor fiber extension. If needed, gently pull apart the duplex sensor fiber extension

from the end with two single connectors, being careful not to bend the fiber with a

radius of less than 35 mm (1.3 inches).

3. Ensure that the sensor fiber extension is long enough to reach the 350 relay from the

bulkhead connector location.

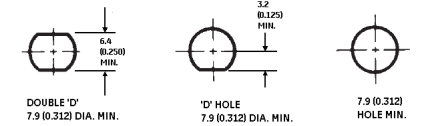

4. Mount the bulkhead connector on the side of the chamber, following the drill hole

dimensions provided. Note that the single bulkhead connector uses washers 11.0 mm

(0.420 in) wide, so the drill holes must be spaced accordingly if the loop sensor path

begins and ends in the same place.

Figure 2-26: Bulkhead connector cutout

5. Install the loop sensor carefully, following all sensor fiber handling guidelines.

6. Plug the ends of the loop sensor into the bulkhead connectors.

7. Plug the single connectors on the sensor fiber extension into the other sides of the

bulkhead connectors, and the duplex connector into the back of the 350 relay

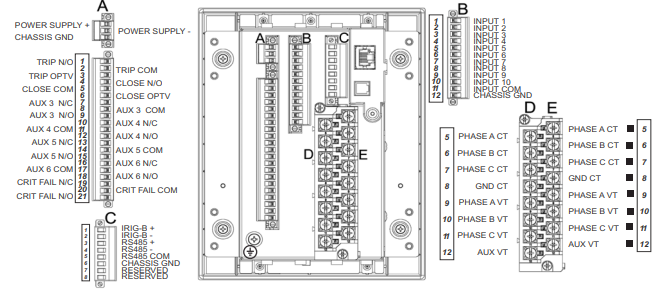

Wire range

Use the following guidelines when selecting wires or lugs to connect to terminal blocks

A,B,C,D,E (Drawout case design), and terminal blocks D,E (Non-drawout case design):

• 12 AWG to 22 AWG (3.3 mm2 to 0.3 mm2): Single wire termination with/without

9.53 mm (0.375”) maximum diameter ring terminals (#8).

• 14 AWG to 22 AWG (2.1 mm2 to 0.3 mm2): Multiple wire termination with matching

wire sizes and stranding. Two wires maximum per circuit.

• 14 AWG to 22 AWG (2.1 mm2 to 0.3 mm2): Multiple wire termination with 9.53 mm

(0.375”) maximum diameter ring terminals (#8). Two ring terminals maximum per

circuit.

• Suggested wiring screw tightening torque, tighten to 12 in-lb (1.35 N-m).

• Minimum suggested temperature rating for the conductors is 75C.

Use the following guidelines when selecting wires to connect to terminal strip F (Drawout

case design), and terminal strips A,B,C (Non-drawout case design):

• 12 AWG to 24 AWG (3.3 mm2 to 0.2 mm2)

• Suggested wiring screw tightening torque: 4.5 in-lbs (0.5 N-m)

• The uncovered communications cable shield connected to the common terminal

should not exceed 1” (2.5 cm) for proper EMC shielding of the communications cable.

Phase sequence and transformer polarity

For correct operation of the relay features, the user must follow the instrument

.png)

.png)

.png)