HIMAHIMatrix Safety-Related Controller F31 03 Manual

Altitude < 2000 m

Housing Standard: IP20

Supply voltage 24 VDC

Table 2: Environmental Requirements

Exposing the HIMatrix system to environmental conditions other than those specified in this

manual can cause the HIMatrix system to malfunction.

2.1.2 ESD Protective Measures

Only personnel with knowledge of ESD protective measures may modify or extend the system

or replace devices.

Device damage due to electrostatic discharge!

When performing the work, make sure that the workspace is free of static, and wear

an ESD wrist strap.

If not used, ensure that the device is protected from electrostatic discharge, e.g., by

storing it in its packaging

Residual Risk

No imminent risk results from a HIMatrix system itself.

Residual risk may result from:

Faults related to engineering

Faults related to the user program

Faults related to the wiring

2.3 Safety Precautions

Observe all local safety requirements and use the protective equipment required on site.

2.4 Emergency Information

A HIMatrix system is a part of the safety equipment of a site. If a device or a module fails, the

system enters the safe state.

In case of emergency, no action that may prevent the HIMatrix systems from operating safely is

permitted.

Product Description

The safety-related F31 03 controller is a compact system in a metal housing with 20 digital

inputs and 8 digital outputs.

The configuration is performed using SILworX, see Chapter 4.3.

The device is suitable for sequence of events recording (SOE), see Chapter 4.2. The device

supports multitasking and reload. For more details, refer to the system manual compact

systems (HI 800 141 E).

The device is TÜV-certified for safety-related applications up to SIL 3 (IEC 61508, IEC 61511

and IEC 62061), Cat. 4 and PL e (EN ISO 13849-1) and SIL 4 (EN 50126, EN 50128 and

EN 50129).

Further safety standards, application standards and test standards are specified in the

certificates available on the HIMA website.

Safety Function

The controller is equipped with safety-related digital inputs and outputs.

3.1.1 Safety-Related Digital Inputs

The controller is equipped with 20 digital inputs. The state (HIGH, LOW) of each input is

signaled by an individual LED.

Mechanical contacts without own power supply or signal power source can be connected to the

inputs.

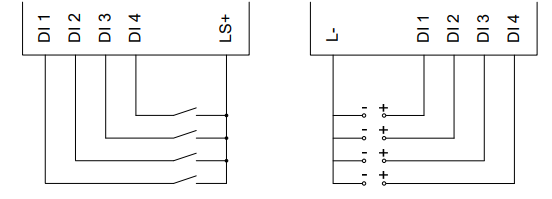

Potential-free mechanical contacts without own power supply are fed via an internal shortcircuit-proof 24 V power source (LS+). Each of them supply a group of 4 mechanical contacts.

Figure 1 shows how the connection is performed.

With signal voltage sources, the corresponding ground must be connected to the input (L-), see

Figure 1.

For the external wiring and the connection of sensors, apply the de-energized-to-trip principle.

Thus, if a fault occurs, the input signals adopt a de-energized, safe state (low level).

If an external wire is not monitored, an open-circuit is considered as safe low level.

Reaction in the Event of a Fault

If the device detects a fault on a digital input, the user program processes a low level in

accordance with the de-energized to trip principle.

The device activates the FAULT LED.

In addition to the channel signal value, the user program must also consider the corresponding

error code.

The error code allows the user to configure additional fault reactions in the user program.

Line Control

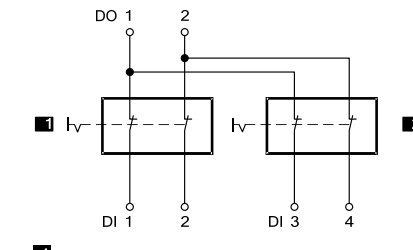

Line control is used to detect short-circuits or open-circuits and can be configured for the F31

system, e.g., on EMERGENCY STOP inputs complying with Cat. 4 and PL e in accordance with

EN ISO 13849-1.

To this end, connect the digital outputs DO 1 through DO 8 of the system to the digital inputs DI

of the same system as follows:

The controller pulses the digital outputs to detect the line short-circuits and open-circuits on the

lines connected to the digital inputs. To do so, configure the Value [BOOL] -> system variable in

SILworX. The variables for the pulsed outputs must begin with channel 1 and reside in direct

sequence, one after the other.

If the following faults occur, the FAULT LED located on the front plate of the controller blinks,

the inputs are set to low level and an (evaluable) error code is created:

Cross-circuit between two parallel wires.

Invalid connections of two lines (e.g., DO 2 to DI 3),

Earth fault on one wire (with earthed ground only).

Open-circuit or open contacts, i.e., including when one of the two EMERGENCY STOP

switches mentioned above has been engaged, the FAULT LED blinks and the error code is

created.

Safety-Related Digital Outputs

The controller is equipped with 8 digital outputs. The state (HIGH, LOW) of each output is

signaled by an individual LED (HIGH, LOW).

At the maximum ambient temperature, the outputs 1...3 and 5...7 can be loaded with 0.5 A

.png)

.png)

.png)