A-BPowerFlex 700 Adjustable Frequency AC Drive

• Flying Start delivers smooth and instantaneous connection into rotating loads, regardless of commanded direction, without the need

for any speed feedback.

• Integral Process PI Control can eliminate the need for a separate process loop controller.

• Inertia Ride-Through offers tripless operation during a prolonged power outage by using the rotating energy that is stored in high

inertia, low-friction loads.

• Position Indexer/Speed Profiler uses a 16-step indexer to provide point-to-point positioning or velocity profiling based on encoder

counts, digital inputs, parameter levels, or time.

• TorqProve™ assures control of the load when transferring control between the drive and a mechanical brake.

• Speed Regulation - Open Loop or Closed Loop

- Slip Compensation delivers a minimum 0.5% speed regulation without feedback hardware.

- Droop allows drives to load share without fighting each other.

- Encoder Feedback provides up to 0.001% speed regulation for the tightest application requirements.

• Torque Regulation - Open Loop or Closed Loop

- Open Loop torque regulation provides 5% regulation.

- Encoder Feedback provides 2% regulation and the ability to hold full load at zero speed.

Unsurpassed Capability in Network Communications

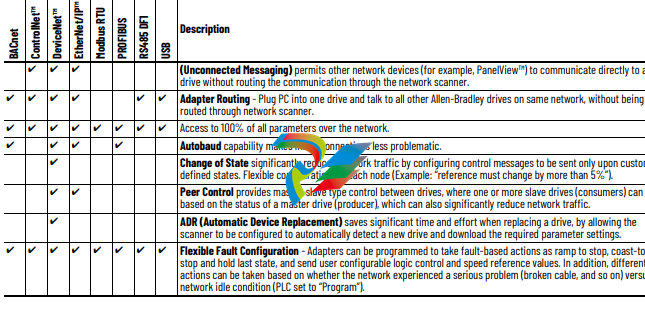

PowerFlex drives are fully compatible with the wide variety of Allen-Bradley DPI™ communication adapters, offering the following benefits:

Drive, Fuse, and Circuit Breaker Ratings

The PowerFlex 700 can be installed with input fuses or an input circuit breaker. National and local industrial safety regulations and/or

electrical codes can determine additional requirements for these installations.

The tables on the following pages provide recommended AC line input fuse and circuit breaker information. See Fusing and Circuit Breakers

below for UL and IEC requirements. Sizes that are listed are the recommended sizes based on 40 °C (104 °F) and the U.S. NEC. Other country,

state, or local codes can require different ratings. Tables with DC link fuse recommendations for DC input drives are also provided.

Fusing

The recommended fuse types are listed below. If available current ratings do not match those listed in the tables that are provided, choose

the next higher fuse rating.

• IEC – BS88 (British Standard) Parts 1 and 2, EN60269-1, Parts 1 and 2(1), type gG or equivalent must be used.

• UL – UL Class CC, T, RK1, or J must be used for Frames 0…6.

Circuit Breakers

The “non-fuse” listings in the following tables include inverse time circuit breakers, instantaneous trip circuit breakers (motor circuit

protectors) and 140M Motor Protection Circuit Breakers (MPCBs) that are rated for use as self-protected combination motor controller

(Frames 0…6 only). If one of these is chosen as the desired protection method, the following requirements apply:

• IEC – Both types of circuit breakers and 140M self-protected combination motor controllers (Frames 0…6 only) are acceptable for IEC

installations.

• UL – Only inverse time circuit breakers and the specified 140M self-protected combination motor controllers (Frames 0…6 only) are

acceptable for UL installations.

Circuit Breaker - inverse time breaker. For US NEC, minimum size is 125% of motor FLA. Ratings that are shown are maximum.

(5) Motor Circuit Protector - instantaneous trip circuit breaker. For US NEC, minimum size is 125% of motor FLA. Ratings that are shown are maximum.

(6) Bulletin 140M devices with adjustable current range must have the current trip set to the minimum range that the device does not trip.

(7) Manual Self-Protected (Type E) Combination Motor Controller, UL Listed for 208V Wye or Delta, 240V Wye or Delta, 480Y/277V or 600Y/347V. Not UL Listed for use on 480V or 600V Delta/

Delta, corner ground, or high-resistance ground systems.

(8) The A1C ratings of the Bulletin 140M devices can vary. See publication 140-TD005 or 140M-TD002.

(9) Maximum allowable rating by US NEC. Exact size must be chosen for each installation.

(10) UL Type 12/IP54 (flange mount) heat sink ambient temperature rating is 40° C/ambient of unprotected drive portion (inside enclosure) is 55° C. The ambient temperature for the UL Type 12/

IP54 standalone drives is 40° C.

(11) Must remove top label and vent plate, drive enclosure rating is IP00, NEMA / UL Type Open.

(12) Frames 0…4 temperature rating is for NEMA / UL Type Open. The adhesive top label must be removed to operate drive at this temperature. Frames 5 and 6 do not have a top label.

(13) Drives have dual current ratings; one for normal duty applications, and one for heavy-duty applications. The drive can be operated at either rating.

(14) Note: 600V class drives below 77 amps (Frames 0…4) are declared to meet the Low Voltage Directive and UK Low Voltage Regulations. It is the responsibility of the user to determine

compliance to the EMC Directive and UK EMC Regulations.

(15) When using a Manual Self-Protected (Type E) Combination Motor Controller, the drive must be installed in a ventilated or non-ventilated enclosure with the minimum volume that is specified

in this column. Application-specific thermal considerations can require a larger enclosure.

.png)

.png)

.png)