A-BPowerFlex 700 Adjustable Frequency AC Drive

Product Overview

The PowerFlex® 700 AC drive offers outstanding performance in an easy-to-use drive that you have come to

expect from Rockwell Automation. The PowerFlex 700 AC drive is designed to control three-phase induction

motors in applications with requirements ranging from the simplest speed control to the most demanding

torque control. The drive has volts per hertz, sensorless vector, and vector control. Vector control includes

Allen-Bradley’s patented Force Technology, which provides world class motor control.

Flexible Packaging and Mounting

• IP20, NEMA / UL Type 1 – For conventional mounting inside or outside a control cabinet. Conduit plate is removable for easy

installation and replacement without disturbing conduit.

• IP54, NEMA / UL Type 12 – standalone, wall mount drives are available for dust-tight applications with power ratings 75...200 Hp

(Frames 5 and 6).

• IP54, NEMA / UL Type 12 – Flange mount drives with an IP00, NEMA / UL Type Open front. These can be installed in a user supplied

cabinet to meet IP54, NEMA / UL Type 12. This allows most heat to be exhausted out the back of the cabinet while keeping the cabinet

protected. Power ratings range 75...200 Hp (Frames 5…6).

• Zero-Stacking™ Drive– Frame 0…6 drives can be mounted next to each other with no reduction of surrounding air temperature rating 50 °C (122 °F). This unique bookshelf design also allows access to one drive without disturbing another.

• Conformal Coating - The drive is coated in an insulator, or non-conducting substance, that helps protect it from moisture, fungus,

dust, corrosion, abrasion, and other environmental stresses caused by highly polluted atmospheres. The coating improves product

lifetime expectancy when exposure to corrosive environment is present. It helps maintain long-term surface insulation resistance,

ensuring operational integrity of the assembly.

Space Saving Hardware Features

• Integral EMC Filtering plus built-in DC bus choke common mode cores and common mode capacitors provides a compact, all-in-one

package solution for meeting EMC requirements. Frames 0…6 only.

• Internal Communications allows you to integrate the drive into the manufacturing process. Status indicators for all internal

communication options are visible on the cover for easy setup and monitoring of drive communications. You can easily manage

information from shop floor to top floor and seamlessly integrate their complete system as they control, configure, and collect data.

• Integral Dynamic Brake Transistor delivers a cost-effective means of switching regenerative energy without costly external

chopper circuits. These internal transistors are available in power ratings 0.5...200 Hp.

• Internal Dynamic Brake Resistor (up to 25 Hp) requires no extra panel space, and supplies a large amount of braking torque for

short periods.

Easy to Use Human Interface Tools

The PowerFlex 7-Class AC drives provide common Human Interface tools that are familiar and easy to use. These include the LCD Human

Interface modules and PC-based configuration tools.

Human Interface Module

The LCD Human Interface modules provide:

• Large and easy to read 7 line x 21 character backlit display

• Variety of languages (English, French, German, Italian, Spanish, Portuguese, Dutch)

• Alternate function keys for shortcuts to common tasks

• “Calculator-like” number pad for fast and easy data entry (Full Numeric version only)

• Control keys for local start, stop, speed, and direction

• Remote versions for panel mount application

Connected Components Workbench Software

Connected Components Workbench™ programming and configuration software leverage proven Rockwell Automation and Microsoft® Visual

Studio® technologies for fast and easy drive configuration, controller programming, and integration with the HMI editor.

The workbench includes:

• an intuitive interface and startup wizards

• localized language support

• online and offline configuration

• context-sensitive help

• supports PowerFlex drives, Micro800™ programmable controllers, and PanelView™ component graphic terminals

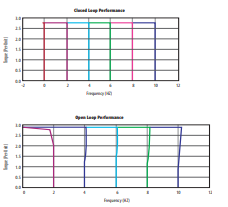

Outstanding Control and Performance

Multiple motor control algorithms allow performance that is matched to the application need:

• Volts/Hertz for simple Fan and Pump applications.

• Sensorless Vector for high torque production over a wide speed range.

• Vector for outstanding torque regulation and excellent low speed/zero speed

performance (w/Vector Control cassette).

The PowerFlex 700 drive's Vector Control uses Allen-Bradley's patented Force Technology

which provides excellent low-speed performance - whether it is operated with or without

feedback. While this industry-leading control provides the highest level of drive performance,

it is as easy to use as any general-purpose drive available.

Drives Features

• Fast-acting Current Limit and Bus Voltage Regulation result in maximum accel/decel without tripping.

• High-speed analog inputs improve drive response to torque or speed commands.

• Programming flexibility allows parameters to be linked within the drive.

.png)

.png)

.png)