A-BAdjustable Frequency AC Drive

1-22

New method of changing speed reference for IP66, NEMA/UL Type 4X rated

drives described.

2-2

Description for Up Arrow and Down Arrow keys revised. 2-4

Fault description for F3 revised. 4-3

Graphic for the “Network Wiring” section revised. C-1

Descriptions for bits 6, 7, and 15 of register address 8192 (Logic Command)

updated.

C-4

New information on reading register address 8192 added. C-4

New information on reading register address 8193 added. C-5

Graphic for the “Connecting an RS-485 Network” section corrected. D-4

New method for inverting sign of PID error added. F-6

Parameter Number Description Page

[PID Invert Error] A167 New 3-44

Parameter Number Description Page

[Control Source] d012 Options 7 and 8 added. 3-5

[Start Source] P036 Description revised for option 6. 3-10

[Relay Out Sel] A055 Description revised for option 20. 3-16

[Relay Out Level] A056 Description revised. 3-17

[Opto Outx Sel] A058, A061 Description revised for option 20. 3-18

[Opto Outx Level] A059, A062 Description revised. 3-19

[Internal Freq] A069 Default value for IP66, NEMA/

UL Type 4X drives is 0.0 Hz.

Default value for IP20 rated drives is

60.0 Hz.

3-22

[PID Trim Hi] A130 Description revised. 3-38

[PID Trim Lo] A131 Description revised. 3-38

ATTENTION: The drive contains high voltage capacitors which take

time to discharge after removal of mains supply. Before working on

drive, ensure isolation of mains supply from line inputs [R, S, T (L1,

L2, L3)]. Wait three minutes for capacitors to discharge to safe voltage

levels. Failure to do so may result in personal injury or death.

Darkened display LEDs is not an indication that capacitors have

discharged to safe voltage levels.

!

ATTENTION: Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery should plan or

implement the installation, start-up and subsequent maintenance of the

system. Failure to comply may result in personal injury and/or

equipment damage.

!

ATTENTION: This drive contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing or repairing this assembly.

Component damage may result if ESD control procedures are not

followed. If you are not familiar with static control procedures,

reference A-B publication 8000-4.5.2, “Guarding Against Electrostatic

Damage” or any other applicable ESD protection handbook.

!

ATTENTION: An incorrectly applied or installed drive can result in

component damage or a reduction in product life. Wiring or application

errors, such as, undersizing the motor, incorrect or inadequate AC

supply, or excessive ambient temperatures may result in malfunction of

the system.

!

ATTENTION: The bus regulator function is extremely useful for

preventing nuisance overvoltage faults resulting from aggressive

decelerations, overhauling loads, and eccentric loads. However, it can

also cause either of the following two conditions to occur.

1. Fast positive changes in input voltage or imbalanced input voltages

can cause uncommanded positive speed changes;

2. Actual deceleration times can be longer than commanded

deceleration times

However, a “Stall Fault” is generated if the drive remains in this state

for 1 minute. If this condition is unacceptable, the bus regulator must be

disabled (see parameter A117). In addition, installing a properly sized

dynamic brake resistor will provide equal or better performance in most

cases.

ATTENTION: To avoid an electric shock hazard, ensure isolation of

mains supply from line inputs [R, S, T (L1, L2, L3)] and wait three

minutes for capacitors to discharge before removing the external cover.

Once the cover is removed, verify that the voltage on the bus capacitors

has discharged before performing any work on the drive. Measure the

DC bus voltage at the DC– and DC+ terminals on the Power Terminal

Block (refer to page 1-13 for Power Terminal descriptions). The voltage

must be zero

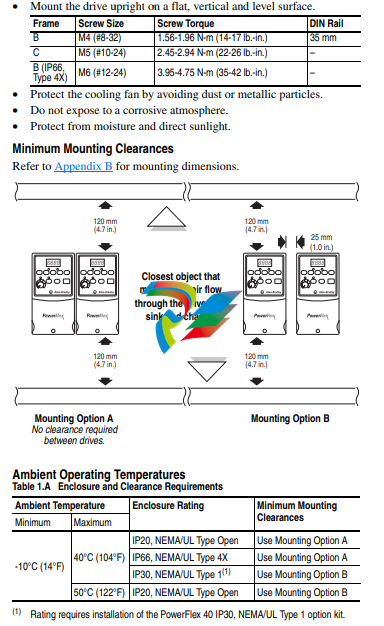

Mounting Considerations

Debris Protection

A plastic top panel is included with the drive. Install the panel to prevent

debris from falling through the vents of the drive housing during

installation. Remove the panel for IP20, NEMA/UL Type Open

applications.

Storage

• Store within an ambient temperature range of -40° to +85°C.

• Store within a relative humidity range of 0% to 95%,

non-condensing.

• Do not expose to a corrosive atmosphere.

AC Supply Source Considerations

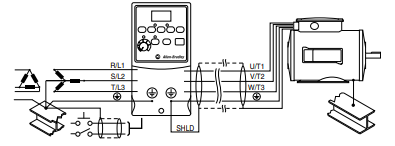

General Grounding Requirements

The drive Safety Ground - (PE) must be connected to system

ground. Ground impedance must conform to the requirements of

national and local industrial safety regulations and/or electrical codes.

The integrity of all ground connections should be periodically checked.

Figure 1.3 Typical Grounding

Ground Fault Monitoring

If a system ground fault monitor (RCD) is to be used, only Type B

(adjustable) devices should be used to avoid nuisance tripping.

Safety Ground - (PE)

This is the safety ground for the drive that is required by code. One of

.png)

.png)