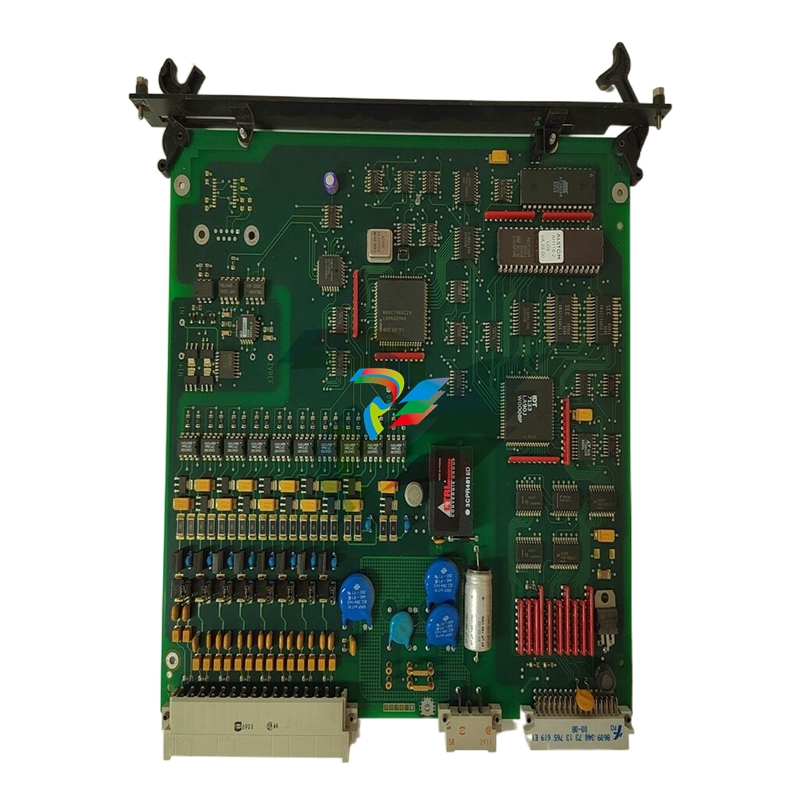

ALSTOM P139 - Micom Ptb 04 ATEX3044 P1393604544AW00E01

The ALSTOM P139 is a highly robust and versatile automation controller designed to meet the demanding requirements of the power industry, petrochemical plants, and general automation processes. Renowned for its superior input/output (I/O) capacity, the P139 supports an extensive array of analog and digital signals, providing seamless integration with complex control systems. This flexibility allows operators to monitor and control multiple parameters simultaneously, boosting reliability and operational efficiency in large-scale industrial settings.

One of the key technical features of the ALSTOM P139 is its modular architecture, which supports a scalable I/O configuration tailored to specific application needs. It typically handles up to 128 digital inputs and outputs and up to 64 analog I/O channels, enabling it to adapt from medium to large automation projects. The device’s high-speed processing unit ensures rapid data acquisition and real-time control, essential for critical applications such as turbine control in power plants or chemical process management in petrochemical facilities. Additionally, the P139 is engineered to operate reliably under harsh environmental conditions, boasting enhanced durability with resistance to temperature extremes, electromagnetic interference, and vibration – features that guarantee long-term operational stability.

Performance-wise, the ALSTOM P139 excels in precision and responsiveness. Its internal algorithms facilitate advanced control functions including PID regulation, fault detection, and predictive maintenance alerts. These capabilities reduce downtime and maintenance costs, while improving safety and productivity. The controller supports multiple communication protocols such as Profibus and Modbus, enabling seamless integration within existing automation networks and compatibility with supervisory control and data acquisition (SCADA) systems.

In practical applications, the ALSTOM P139 is widely used for controlling and monitoring critical processes in power generation facilities, where precise regulation of electrical output and system protection is paramount. In the petrochemical sector, the P139 manages complex chemical reactions and safety interlocks, helping to optimize throughput while ensuring compliance with stringent safety standards. General automation tasks such as manufacturing line control, environmental monitoring, and energy management also benefit from the P139’s flexibility and reliability.

When compared to other ALSTOM automation products, the P139 stands out for its balanced combination of high I/O capacity and rugged design. Unlike the ALSTOM SCR Control Unit, which is specialized for thyristor control in power electronics, the P139 provides broader automation functionality with extensive I/O scalability. Similarly, while the ALSTOM MICOM P139 shares the name designation, the P139 controller discussed here offers enhanced modularity and communication options that make it more adaptable for integrated automation solutions. Other products like the ALSTOM 20x4500/40E and ALSTOM 20x4496 provide targeted control features but lack the comprehensive I/O and protocol support that the P139 delivers.

Alongside the ALSTOM P139, complementary models such as the ALSTOM Profibus DP FBK PBD MV1 65B12 enable streamlined communication interfaces, while the ALSTOM Power 20x4496 and ALSTOM 20x4373/50BCOAT offer specialized power monitoring and control functions. The ALSTOM EPSC-0070 serves as an excellent relay protection device, and the ALSTOM PIB315B and ALSTOM PIB100G modules expand input/output capabilities for complex automation scenarios. The ALSTOM SKIIP2013GB172-4DK0197 power modules and ALSTOM Drives 28x3548 complement the P139 by offering advanced motor control and power electronics integration. This ecosystem of ALSTOM automation products ensures scalable, reliable, and efficient solutions tailored to diverse industrial challenges.

In summary, the ALSTOM P139 is a cornerstone product in the ALSTOM automation portfolio, delivering unmatched performance and adaptability for the power industry, petrochemical, and general automation fields. Its robust design, extensive I/O capacity, and advanced communication capabilities make it a preferred choice for projects demanding high precision and reliability. With seamless integration alongside models like the ALSTOM 20182-136-01 and ALSTOM PS421, the P139 ensures optimized control solutions that enhance productivity and safety across various industries. Whether upgrading existing systems or deploying new installations, the application of P139 in power industry, petrochemical, and general automation environments guarantees superior control and operational excellence.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|