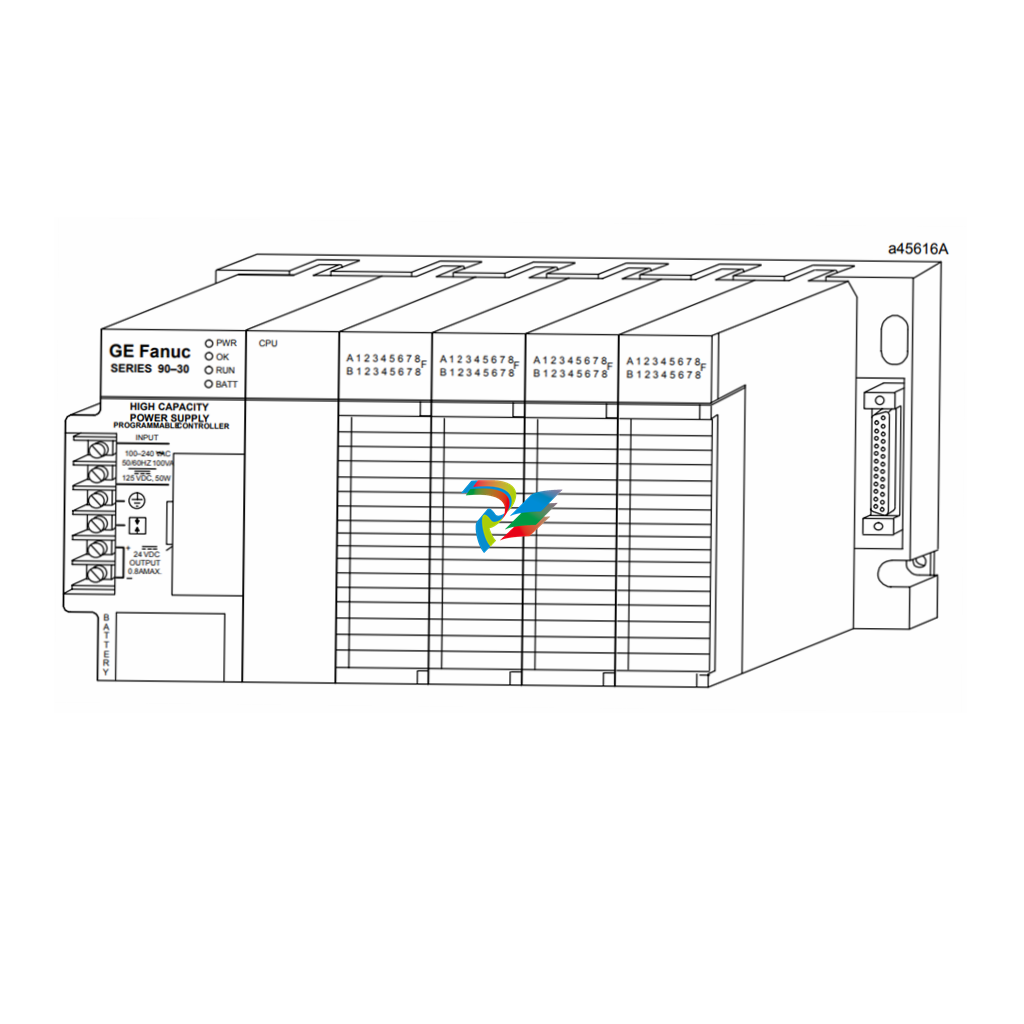

GE IC697MDL940 - Industrial Output Relay Module

The GE IC697MDL940 is a high-performance digital input/output (I/O) module designed to meet the rigorous demands of modern industrial automation, particularly within power industry, petrochemical, and general automation applications. Engineered by GE, a leader in automation products, the IC697MDL940 offers robust features that ensure reliable operation, scalability, and seamless integration within complex control systems.

This module boasts an impressive capacity of 64 digital inputs and 64 digital outputs, enabling comprehensive monitoring and control of industrial processes. Its input channels are capable of handling a wide range of voltage levels, ensuring compatibility with various sensor signals and signal conditioning requirements. The output channels are designed for high-current switching, supporting loads up to 2A per channel, which makes it suitable for controlling actuators, relays, and other heavy-duty devices. The module's durability is evidenced by its sturdy construction, capable of withstanding harsh environmental conditions such as extreme temperatures, vibrations, and electrical noise commonly encountered in power plants and petrochemical facilities.

Performance metrics of the GE IC697MDL940 are exemplary, featuring fast scan times that facilitate real-time control and monitoring, essential for maintaining safe and efficient operations. Its high reliability is supported by extensive diagnostics and error detection capabilities, allowing quick troubleshooting and minimizing downtime. Additionally, the module integrates seamlessly with GE’s family of automation controllers, including models like IC695PSA140E and IC694PWR321, offering a cohesive platform for complex automation systems.

In real-world scenarios, the GE IC697MDL940 excels in applications such as monitoring turbine operations in power plants, controlling valve actuators in chemical processing, or managing conveyor systems in manufacturing plants. Its high I/O count and robust design make it ideal for large-scale automation projects requiring extensive digital input/output handling. For example, in petrochemical complexes, the module can supervise multiple safety interlocks and process signals simultaneously, ensuring compliance with stringent safety standards.

Compared to other models in GE’s automation lineup, such as the IS220PDIAH1AD or the IS200DTAOH1ABA, the IC697MDL940 emphasizes high-density I/O capacity and ruggedness, making it particularly suited for extensive distributed control systems. While models like the IS220VCRCH1BBC focus on analog signals, the IC697MDL940 specializes in digital signaling, providing a complementary function within integrated automation solutions. Similarly, models like the IC200PNS002 and IC695CPU320-CF serve as controllers or communication interfaces, whereas the IC697MDL940 acts as a vital I/O hub.

Alongside the GE IC697MDL940, we also offer models such as the GE IS220PDIOS1A for isolated digital inputs, and the GE DS3800NTCF1C1C for communication tasks, catering to diverse automation needs. The GE IC695PSA140E offers power supply functions, forming part of the comprehensive automation environment, while the GE IS200VCRCH1BBC provides analog input capabilities that complement the digital I/O provided by the IC697MDL940.

In summary, the GE IC697MDL940 stands out as a versatile, durable, and high-capacity digital I/O module within GE’s extensive automation product portfolio. Its application in power industry, petrochemical, and general automation underscores its importance as a reliable backbone for complex control systems. Whether used to automate critical safety systems or streamline large-scale process control, the IC697MDL940 exemplifies GE’s commitment to delivering innovative, high-quality automation products. Its compatibility with other models like the IS220PDIAH1AD, IS200DTAOH1ABA, and IC695CPU315 ensures flexible integration, making it an indispensable component for advanced industrial automation solutions.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|