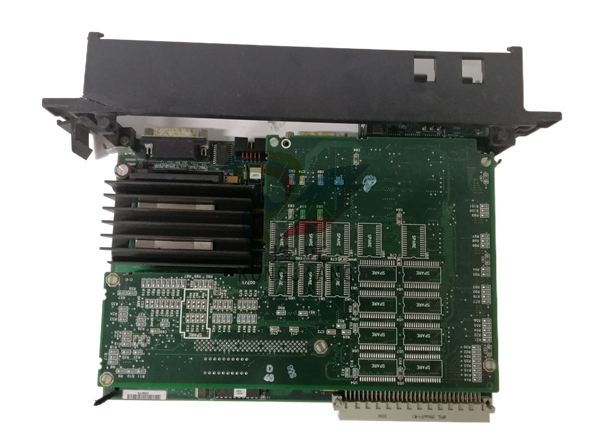

Honeywell 4409SMM - / 4409SMM (USED TESTED CLEANED)

The Honeywell 4409SMM stands out as a robust and versatile component within Honeywell’s extensive portfolio of automation products, specifically engineered for demanding environments such as the power industry, petrochemical plants, and general automation sectors. This model delivers exceptional performance through its advanced input/output (I/O) capacity, rugged durability, and precise operational metrics, making it an indispensable asset for critical industrial applications.

At the core of the Honeywell 4409SMM’s technical prowess lies its high-density I/O configuration which supports extensive signal integration, facilitating seamless monitoring and control of complex industrial processes. Its input channels are designed to handle a wide range of sensor types, including analog, digital, and high-speed pulse inputs, while the output capacity ensures reliable actuation and communication with downstream equipment. Built with industrial-grade components, the 4409SMM offers superior resistance to environmental stressors such as extreme temperatures, vibration, and electromagnetic interference, ensuring uninterrupted operation even in the harshest settings.

One of the defining performance metrics of the Honeywell 4409SMM is its rapid response time combined with precise signal processing capabilities. This ensures real-time data acquisition and control, critical for maintaining safety and efficiency in power generation plants and petrochemical processing units. Furthermore, the unit’s compatibility with Honeywell’s proprietary communication protocols enhances its integration within larger automation systems, allowing for scalable and flexible deployments.

The application of the 4409SMM in the power industry is particularly noteworthy. It excels in monitoring turbine controls, generator status, and auxiliary systems, providing operators with reliable and timely feedback to optimize energy production and prevent unscheduled downtime. In petrochemical environments, the 4409SMM’s resilience to corrosive atmospheres and its ability to process diverse input signals make it ideal for managing complex chemical reactions, pressure monitoring, and safety interlocks. Its versatility also extends to general automation tasks, where it supports factory automation, process control, and infrastructure management with equal efficiency.

Comparing the Honeywell 4409SMM to other Honeywell automation products reveals several unique advantages. For example, unlike the Honeywell 51401477-100 and Honeywell 51403578-100 models, which focus primarily on specific sensor input functions, the 4409SMM offers a more comprehensive I/O interface, enabling broader system integration. While the Honeywell RM855 and Honeywell DL-950 serve as reliable instrumentation modules, the 4409SMM’s enhanced durability and faster processing speed make it better suited for mission-critical applications in volatile industrial environments. Additionally, compared to models like the Honeywell DE132-0-A-BB-0-Z-1-0C-EE0-00 and Honeywell DMX-A-6212, the 4409SMM provides greater flexibility in terms of input/output variety and communication compatibility, simplifying system architecture.

Alongside the Honeywell 4409SMM, we also offer complementary solutions such as the Honeywell CC-PAIN01 and Honeywell PGM-7360 for advanced process monitoring and control, as well as the Honeywell 92977 and Honeywell 51108088-200 for enhanced signal conditioning and data acquisition. For applications requiring extended control capabilities, the Honeywell 51401392-100 and Honeywell BK-G100 provide reliable expansions. Furthermore, integrating the Honeywell 965-1216-011 and Honeywell AL300 with the 4409SMM creates a powerful automation ecosystem that enhances overall operational efficiency and safety.

This synergy between the Honeywell 4409SMM and other models underscores Honeywell’s commitment to delivering comprehensive automation solutions tailored to the unique challenges of the power, petrochemical, and general automation industries. The 4409SMM is not just a standalone product but a critical component that integrates seamlessly into broader Honeywell systems, offering unparalleled performance, durability, and scalability.

In summary, the Honeywell 4409SMM is a high-performance, durable automation product optimized for complex industrial environments. Its superior input/output capacity, rugged design, and rapid processing capabilities make it ideal for the application of 4409SMM in power industry, petrochemical, and general automation sectors. When combined with other Honeywell products such as the Honeywell TSENALMOX-05682 and Honeywell ED-600, it forms the backbone of resilient, efficient, and scalable automation infrastructures. For organizations seeking reliable and versatile automation solutions, the Honeywell 4409SMM represents a smart investment that delivers long-term operational excellence.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|