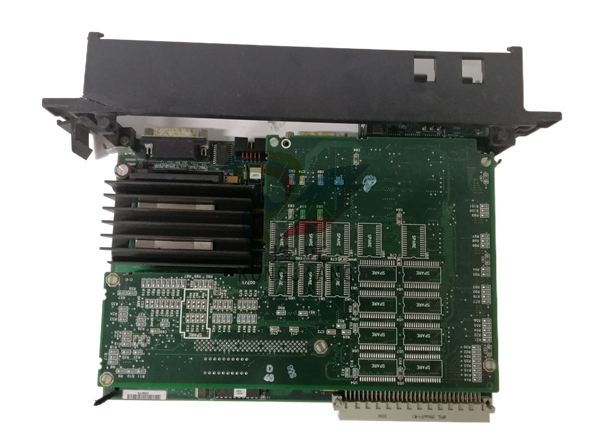

Honeywell CC-PDIS01 - PLC Module Brand New Fast Shipping FedEx or DHL

The Honeywell CC-PDIS01 is a robust and highly reliable automation controller designed specifically for demanding environments such as the power industry, petrochemical plants, and general automation applications. Engineered with precision and durability in mind, the CC-PDIS01 stands out for its exceptional input/output (I/O) capacity, high-performance processing capabilities, and unmatched resilience under harsh operating conditions.

With an extensive I/O configuration, the Honeywell CC-PDIS01 supports numerous digital and analog signals, enabling seamless integration with a wide range of sensors, actuators, and control devices. This flexibility is essential for complex automation systems where precision and real-time responsiveness are critical. The controller boasts a fast processing speed paired with low latency communication protocols, ensuring efficient data handling and swift decision-making on the factory floor or within critical infrastructure systems. Additionally, the CC-PDIS01 is built to withstand extreme temperatures, vibration, and electrical noise, making it an ideal solution for rugged industrial settings.

In real-world usage, the application of the Honeywell CC-PDIS01 in the power industry is particularly noteworthy. It facilitates the monitoring and control of electrical substations, power generation units, and distribution networks, contributing to enhanced grid reliability and operational safety. In the petrochemical sector, the CC-PDIS01 excels at managing complex chemical processing lines, providing precise control over temperature, pressure, and flow parameters to optimize output and maintain stringent safety standards. General automation applications benefit from the device’s adaptability, where it manages diverse machinery and production lines, ensuring consistent quality and minimizing downtime.

When compared to other Honeywell automation products, the CC-PDIS01 demonstrates distinct advantages in scalability and integration. For instance, while the Honeywell CC-TAON01 is known for its temperature sensing capabilities and the Honeywell CN565 excels in signal conditioning, the CC-PDIS01 offers a more comprehensive control solution with enhanced I/O versatility and processing power. Similarly, unlike the Honeywell DM106-0-B-00-0-R-1-00000-000-E0, which focuses primarily on data acquisition, the CC-PDIS01 combines acquisition with advanced processing and control functionalities, enabling it to serve as a central automation hub.

Alongside the Honeywell CC-PDIS01, several complementary models enrich Honeywell’s automation portfolio. The Honeywell PX65A pressure transmitter and the Honeywell ASDX015D44R differential pressure sensor offer precise measurement inputs that can be directly interfaced with the CC-PDIS01 for refined process control. For environmental monitoring, the Honeywell 51104410-100 and Honeywell 51305890-175 sensors provide vital data streams. The Honeywell BK-G40 and Honeywell W7704A-1004 relay modules support expanded control outputs, enhancing system flexibility. Moreover, the Honeywell 51403896-200 and Honeywell 51304584-200 I/O modules can be integrated seamlessly to increase channel availability, making the CC-PDIS01 a highly adaptable controller for varied setups.

The Honeywell CC-PDIS01’s design also incorporates advanced diagnostics and communication features, including compatibility with modern industrial protocols, which are essential for Industry 4.0 environments. This is a significant step above the Honeywell DR45AT-1100-00-011-A-00000E-0 and Honeywell DR45AT-1000-00-101-0-100000-0 models, which, while reliable, offer more limited connectivity options. The CC-PDIS01’s enhanced network capabilities facilitate remote monitoring and control, improving operational efficiency and reducing maintenance costs.

In summary, the Honeywell CC-PDIS01 is a versatile and powerful automation controller tailored for the rigorous demands of the power industry, petrochemical plants, and general automation tasks. Its broad I/O capacity, robust construction, and advanced performance metrics position it as a superior choice among Honeywell automation products. When deployed alongside complementary models such as the Honeywell CC-PCNT01 for temperature control, Honeywell 620-3590 pressure sensors, and Honeywell 51309276-150 input modules, the CC-PDIS01 creates a comprehensive and efficient automation system capable of optimizing industrial operations.

For businesses seeking reliable automation solutions, the Honeywell CC-PDIS01 offers not only enhanced performance but also seamless integration with other Honeywell components, making it an indispensable part of modern industrial automation strategies. Its proven application in the power industry, petrochemical sector, and general automation underscores its role as a cornerstone device in Honeywell’s extensive automation product lineup.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|